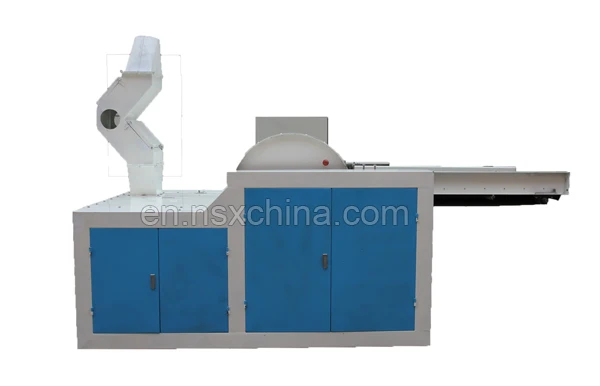

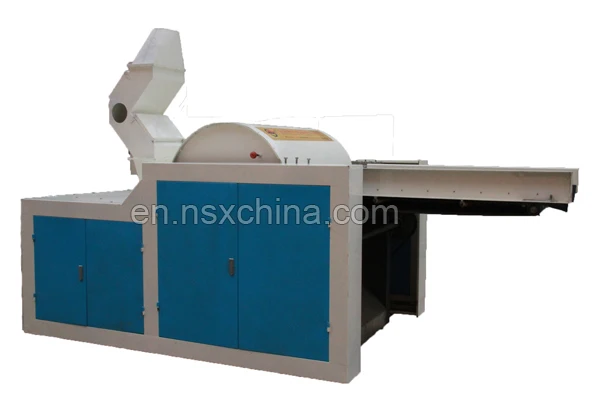

NSX-FS500 пряжа нейлоновая джутовая нетканое текстильное волокно полиэфирная ткань скребок спиннинг многокомпонентная машина для переработки

- Категория: Станки для текстильного сырья >>>

- Поставщик: Qingdao,New,Shunxing,Environmental,Protection&,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.80 $* | 0.59 $* |

| Aug-16-2025 | 0.39 $* | 0.38 $* |

| Jul-16-2025 | 0.60 $* | 0.99 $* |

| Jun-16-2025 | 0.3 $* | 0.96 $* |

| May-16-2025 | 0.58 $* | 0.92 $* |

| Apr-16-2025 | 0.87 $* | 0.38 $* |

| Mar-16-2025 | 0.39 $* | 0.70 $* |

| Feb-16-2025 | 0.77 $* | 0.39 $* |

| Jan-16-2025 | 0.78 $* | 0.4 $* |

Характеристики

NSX-FS500 yarn nylon jute yarn nonwoven textile fiber polyester Fabric Scrap spinning waste Multi combination Recycling Machine

NSX-FS500 yarn nylon jute yarn nonwoven textile fiber polyester Fabric Scrap spinning waste Multi combination Recycling Machine

Full-closed design

This line,which designed and manufactured based on the advanced experience,is the comprehensive characteristic of the fiber peocessing machines at home and abroad.To be certificated,this line basically mmet the requirements of high quality,high output,low consumption,and have advantages such as compact model,easy operation,safety,etc.

The line designed to use the tearing cylinder fast-moving mechanical centrifugal force to exclude impurities from cotton material and tear material,compared to the trodictional processing technology of fiber tearing,and it keeps the fiber length ang less cotton knots.The line is the ideal type to process the old quilter cornor,waste yarn,cloth,linen and other textile waste material.

Mechanical (Special indication :) | |

Capacity | Processing capacity : hard waste polyester:300-400kg/hour Fabric (any material) knitting and weaving: 400-500kg/hour |

Power | 171kw (start up) running condition:85kw |

Color | BLUE AND WHITE (RAL5009 AND RAL 7044) |

MATERIAL | Q235-A/S235 Carbon steel (INDUSTRY STANDARD:GB/T700-2006) |

Design execution | DIN-metrical |

Voltage | 380v/50hz 3phase/ customer requirement |

Main motor | D&D (4&8 class main motor ) |

Electric cabinet | SIEMENS S7 PLC TOUCH PANEL |

Operation | Switching or touch panel |

Pin Cylinder | Aluminum spiked bar/strong tapered steel pins (GB/T699-1999) |

Steel pins | #75 carbon steel and quenching 820℃ (GB/T699-1999) |

Wire cylinder | HT-350 GRAY PIG IRON( GB/T9439-2010 &GB /9439-88) |

Wires | White shark brand (ISO9001/CE) |

Bearing | SKF ----------(Self-aligning ball bearing ) rake≤3° |

Axis/feeding roll | DIN45C steel with quenching 840℃/ rigidity(58-62HRC) |

Electrical material | Schneider & Siemens |

Operation | Switching or touch panel |

Condenser | Big drum on the top of the chute feeding system with mote removing |

Blade of cutter | Import from Japan and strong blade ----62HRC. |

Lubrication system | Automatic lubrication system (for each bearing of the machine) |

Drive Chain | C67E steel with quenching 830℃±20℃,oil cooling . (GB/T 1222-2007) |

Motor wheel | HT-250 pig gray iron ,Parkerizing ,dynamic balance test (EN standard) |

Drive sprocket | DIN 45C steel tempering 600℃ ,≥55HRC |

Feeding roll Subplate | Casting steel -----ZG270-500 |

Magnet | AlNiCo Magnet IEC404-5 |

Side cover | 1.5 mm thickness carbon steel with spray painting |

Feeding spring & scale pillar |

|

Packed in wooden cases.

Water transport

NSX-FS500 yarn nylon jute yarn nonwoven textile fiber polyester Fabric Scrap spinning waste Multi combination Recycling Machine