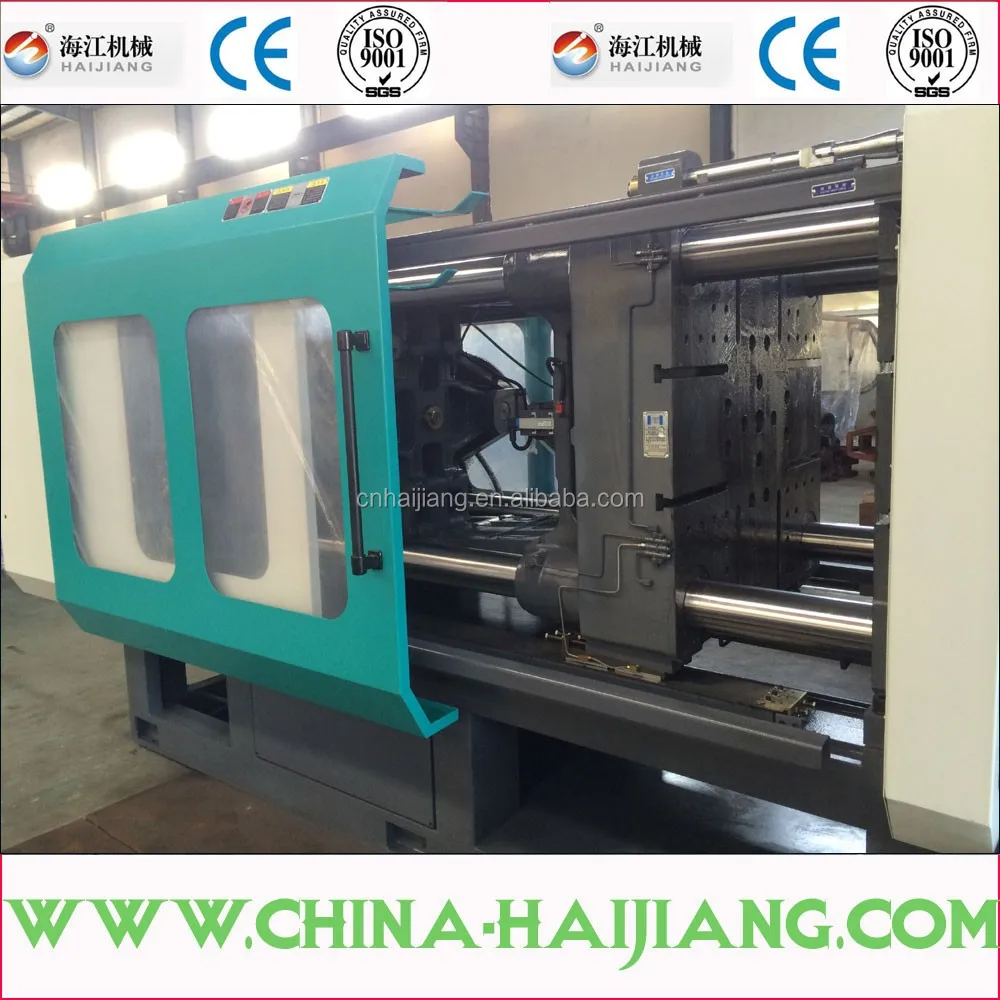

50T ПЭТ машина для литья под

- Категория: Установка для инжекционного прессования >>>

- Поставщик: Ningbo,Haijiang,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 11900.88 $* | 12495.93 $* |

| Aug-16-2025 | 11800.15 $* | 12390.27 $* |

| Jul-16-2025 | 9900.52 $* | 10395.79 $* |

| Jun-16-2025 | 11600.76 $* | 12180.72 $* |

| May-16-2025 | 10100.58 $* | 10605.36 $* |

| Apr-16-2025 | 11400.92 $* | 11970.38 $* |

| Mar-16-2025 | 11300.87 $* | 11865.81 $* |

| Feb-16-2025 | 11200.88 $* | 11760.68 $* |

| Jan-16-2025 | 11100.24 $* | 11655.72 $* |

Характеристики

We supply different types of injection molding machines such as double color injection moulding machine, PET preform injection moulding machine, fast speed plastic injection machine, servo motor injection moulding machine and variable pump plastic injection moulding machine, Parameters of 50T PET preform plastic injection moulding machine as below;

SPECIFICATION | HJK50 | ||

| A | B | |

INJECTION UNIT | |||

Screw Diameter | mm | 28 | 32 |

Screw La/D Ration | L/D | 20 | 17.5 |

Shot Size(Theoretical) | cm3 | 63 | 82 |

Injection Weight(PS) | g | 57 | 73 |

Injection Rate | g/s | 55 | 66 |

Injection Pressure | MPa | 168 | 129 |

Screw Speed | rpm | 0-175 | |

CLAMPING UNIT | |||

Clamp tonnage | KN | 500 | |

Opening stroke | mm | 240 | |

Space Between Tie Bars | mm | 280*260 | |

Max.Mold Height | mm | 300 | |

Min.Mold Height | mm | 140 | |

Ejector Stroke | mm | 55 | |

Ejector Tonnage | KN | 18 | |

OTHERS | |||

Max.Pump Pressure | MPa | 16 | |

Pump Motor Power | KW | 5.5 | |

Heater Power | KW | 3.1 | |

Machine Dimension(L*W*H) | m | 2.6*0.75*1.37 | |

Machine Weight | t | 1.5 | |

Oil Tank Capacity | L | 190 | |

Main features;

Double-cylinder balanced injection system;

Multi-stage pressure &speed injection;

Back pressure adjustment device;

Low pressure mold protection;

Single hydraulic core pulling and inserting;

Multiple hydraulic ejector knock-out;

Mechanical, electrical safety device;

Auto lubrication system;

Hydraulic pressure full proportional control;

Computer control system;

Molding data memory system;

Automatic mould adjust function.

Energy saving with variable pump;

Five-point inward moving toggle system ensure high rigidty and precision for mold clamping and also reducing stress and stain effects;

Oil pipelines are positioned for aesthetic appearance and easy for maintenance;

The moving platen is fitted with adjustable slide support system to improve platen parallelism and provide better tie bar and mould protection and lengthen the working lifetime;

Nozzle alignment is provided using a simple mechanism with fine adjustment for accurate centering.

Special designed screw for PET preforms, we provide turn-key project for bottle making lines of which include PET preform injection moulding machine, blowing machine, auxiliaries.

PET preforms made by the injection molding machine;

Mold cavities can be designed 1 mold 2 cavities, 1 mold 4 cavities, 1 mold 8 cavities, 1 mold 12 cavities, 1 mold 16 cavities, and as most one mold 96 cavities, per customer's daily capacity requirements.

Neck size including 28mm,30mm,34mm and etc.

Bottle size from 150ML to 20L.

One mold 32 cavities;