Китайский поставщик новый продукт изготовленный на заказ пластиковый штекер для розеток по хорошей

- Категория: >>>

- Поставщик: Shanghai,Yuanhai,Plastic,Mould,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.43 $* | 0.13 $* |

| Aug-19-2025 | 0.31 $* | 0.28 $* |

| Jul-19-2025 | 0.79 $* | 0.38 $* |

| Jun-19-2025 | 0.38 $* | 0.21 $* |

| May-19-2025 | 0.34 $* | 0.29 $* |

| Apr-19-2025 | 0.40 $* | 0.75 $* |

| Mar-19-2025 | 0.21 $* | 0.75 $* |

| Feb-19-2025 | 0.13 $* | 0.66 $* |

| Jan-19-2025 | 0.27 $* | 0.16 $* |

Характеристики

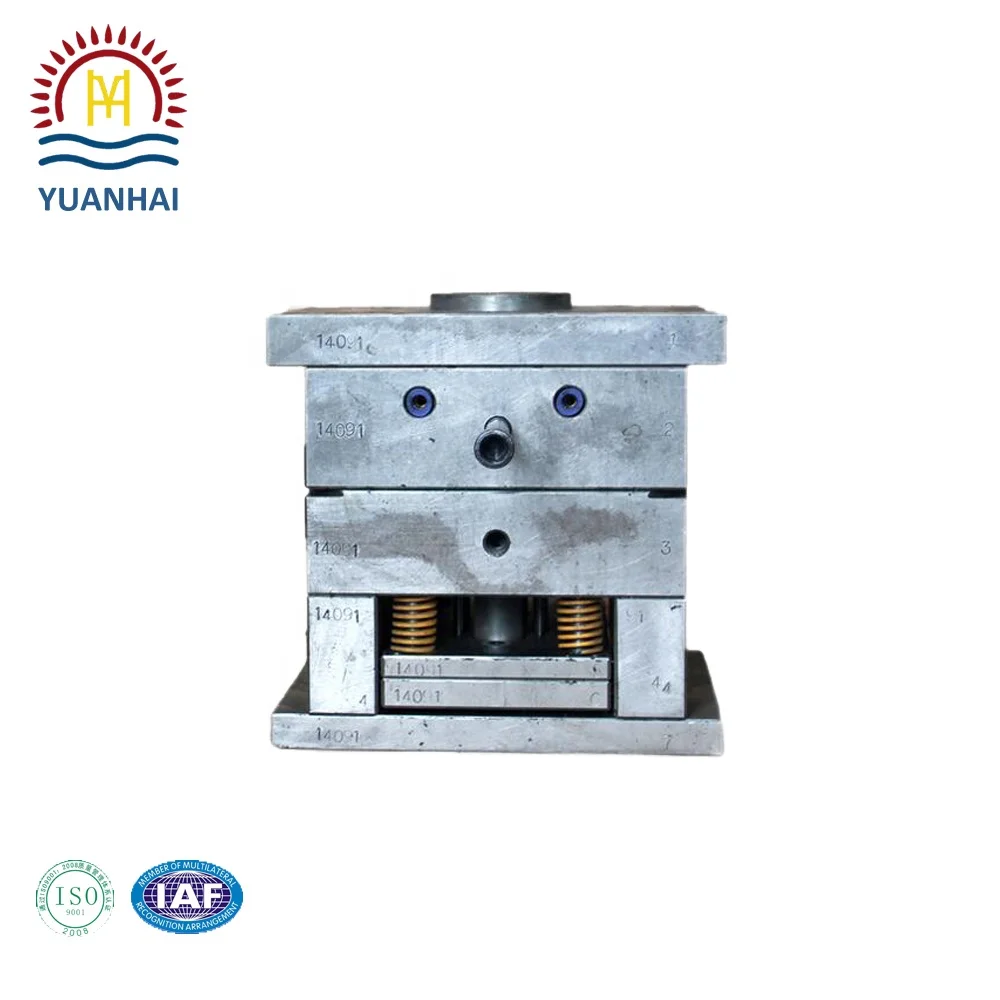

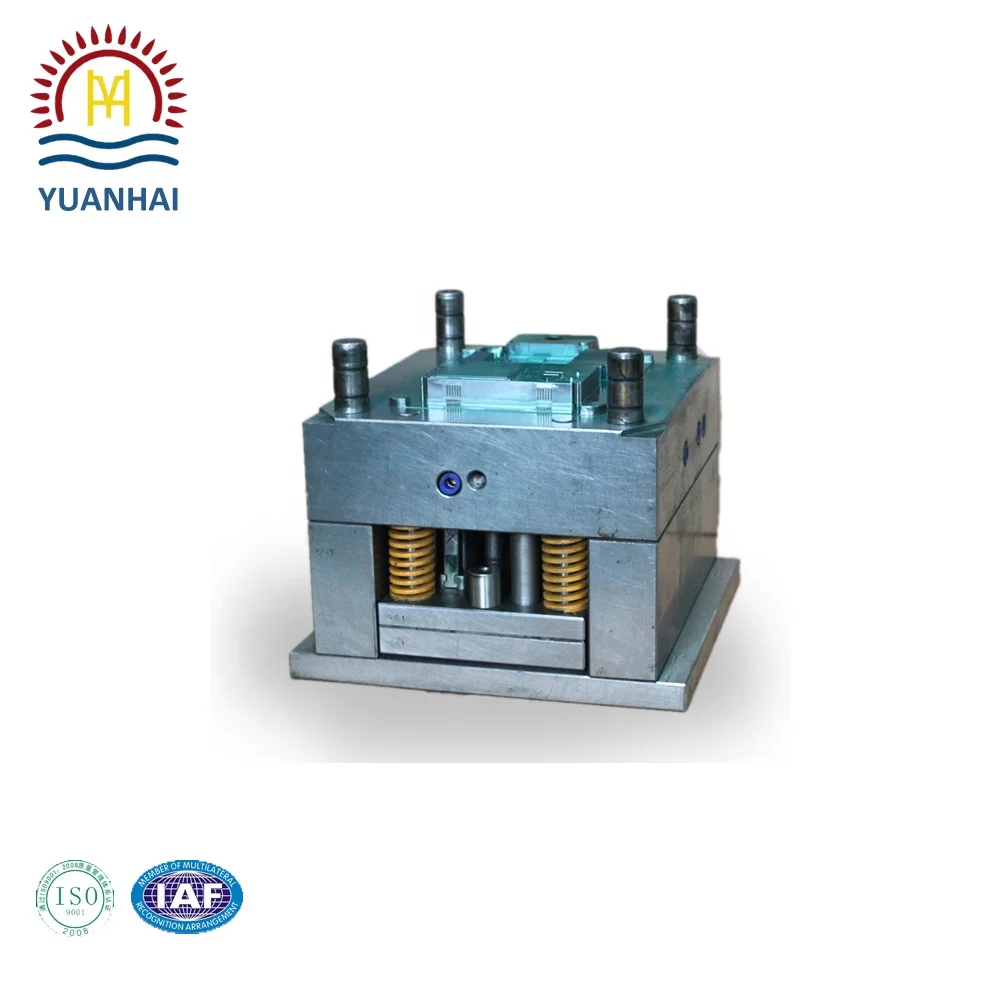

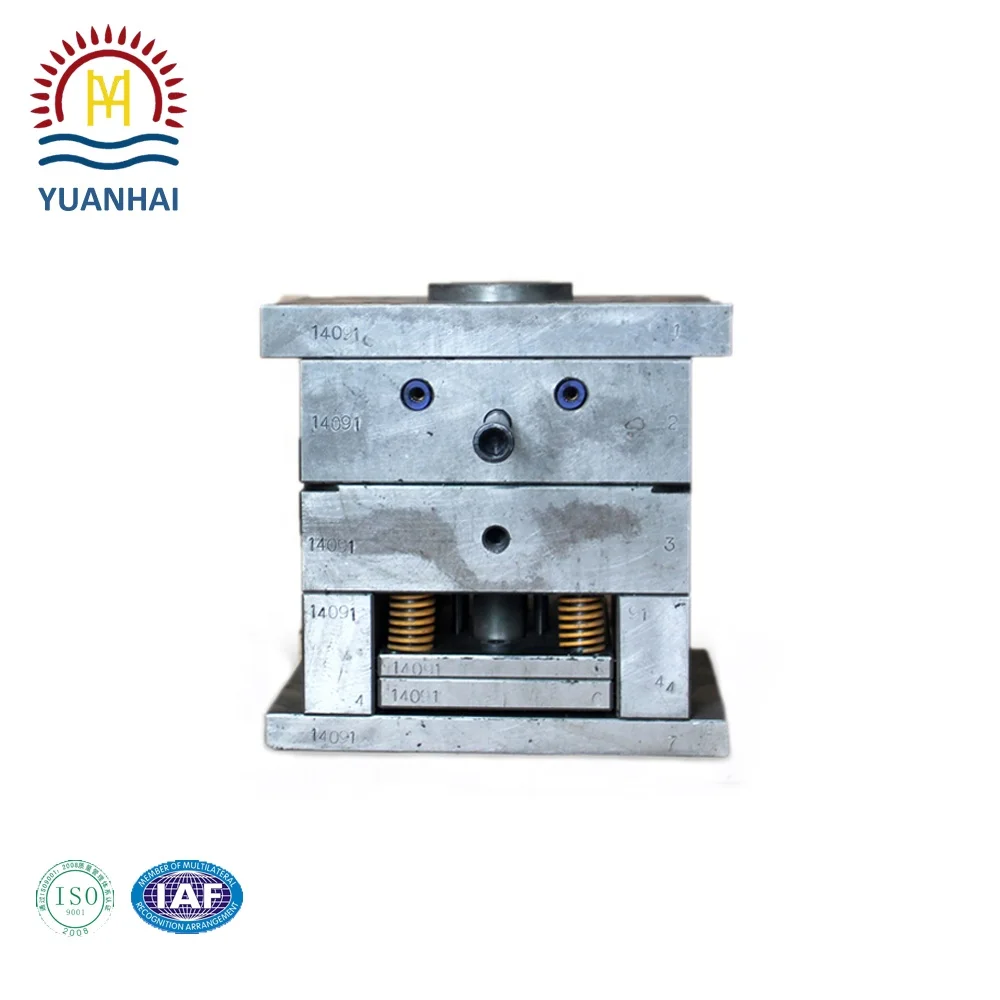

China Supplier New Product Custom Plastic Socket Plug Manufacture For Good Price

General specifications:

TECHNICAL SPECIFICATIONS | ||

Type of mould | Injection mould | Small,medium,large mold |

Mold Material | S136, P20, 718H , 2738 , NAK80 ,1.2311 etc | |

Nr of Cavities | 1+1,1+2+1,2+2,4+4,Single or mutilcativies | |

Cycle time | 10-30seconds | |

Injection machine | 90-1000ton | |

Life span of mold | 300k-1000k | |

Shrinkage | ||

Product Material | PE , PP, HDPE , PPR , PVC , PP , PS , PET , ABS , PC , etc | |

Injection Type | Hot Runner | QTY of Drops |

| Cold Runner | Hot sprue,Sequential Injection |

Gate Point | Edge gate, Pin point gate, Sub gates, Fan gate, bayer | |

Surface finish | Tech polish, High gloss, Texture,VDI 3400 | |

Mould hot treatment | Tempering , Quending , Nitriding | |

Main Processing Equipment | Sodick, Seiki, CNC , high speed carve , EDM ,wire cut , drill | |

Design Group

Tooling Workshop

Mould Making Step

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellent ,but simple design.

8.Good after-service

9.Punctual delivery time

Shanghai Yuanhai Plastic Mould Co., Ltd. is located in Qingpu District of Shanghai ,and has evolved to be one of the leading customized injection mould manufacturer.Our factory covers an area of one thousand square meters. We are strong in technology and specialized in plastic, die casting, rubber mold design and manufacture.

After nearly a decade of development, we now have more than forty staff members including 25 mold technicians and 9 mold modeling and product design engineers. In particular, our company adopts 3D laser scanners to aid in product development and mold design engineering departments.

We have our own complete moulding design centre. The CNC and CAD/CAM capacity and processing equipment have been qualified to ensure high quality products, Our company consistently insists on development depending on trustworthiness, existence depending on quality, scientific research depending on development, benefits depending on management.

We have our own mold tooling workshop,specialize in OEM service.

Our team:

The injection workshop:

Certificate

Other plastic injection molds:

Package

- Moulding Parts

- Inner Packing:Pack in Wrap bag or Paper Box

- Outer Packing:Strong Carton

- Plastic Mould

- Inner Packing:Pack in Wrap bag

- Outer Packing:Wooden Pallet

- Our Package is strong enough for sea ,inland shipping and air

- As Per customer Request

Payment Terms

- Shipping Porting :Shanghai China

- T1(First Testing) Sample :25 Days more or less

- Leading Time:35 Days around

- Payment Method:30% for deposit by T/T ,40% for first Testing ,the balanced paid before shipping,L/C,Western Union ,MoneyGram ,etc .

After Sales Service

- Pls contact us in team after you receive the moulds

- Tel:0086-21-67679181 Fax:0086-21-57670797