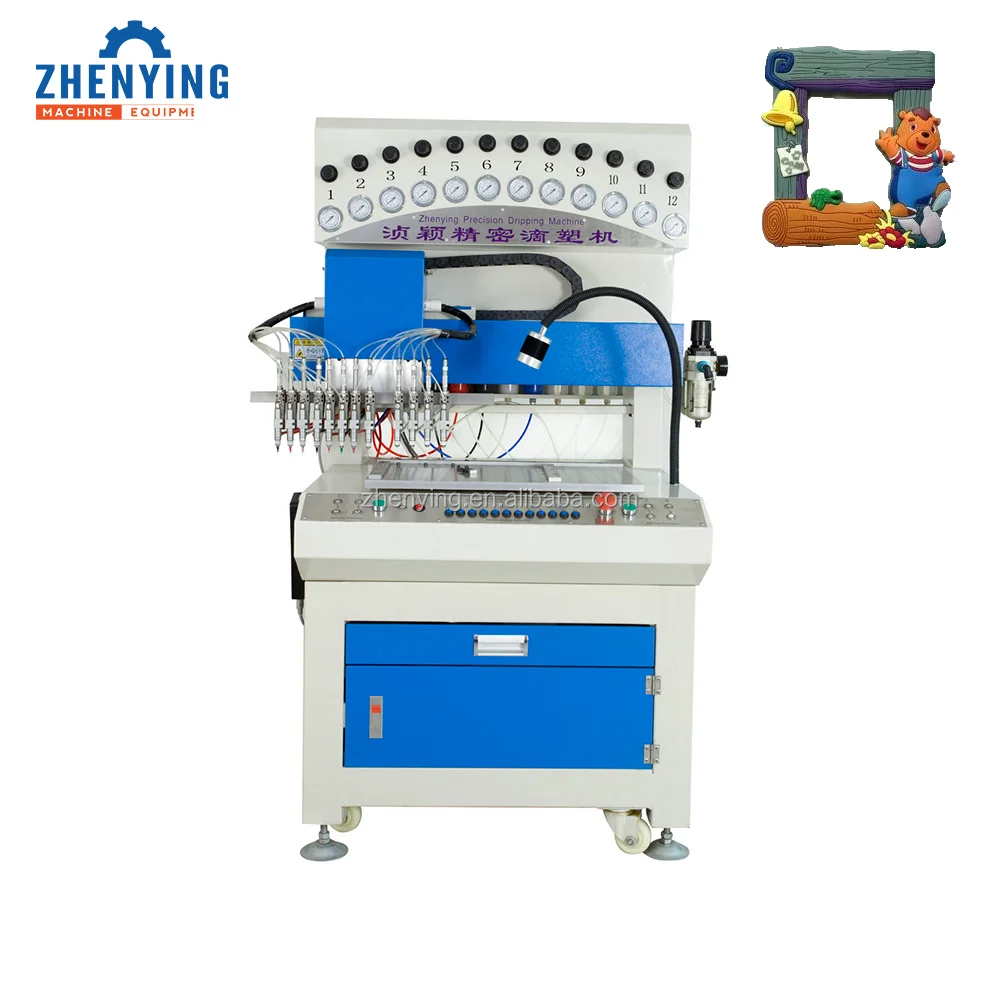

Автоматическая капельная машина для

- Категория: Rubber Product Making Machinery >>>

- Поставщик: Dongguan,Zhenying,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.73 $* | 0.2 $* |

| Aug-15-2025 | 0.36 $* | 0.59 $* |

| Jul-15-2025 | 0.90 $* | 0.94 $* |

| Jun-15-2025 | 0.17 $* | 0.64 $* |

| May-15-2025 | 0.39 $* | 0.70 $* |

| Apr-15-2025 | 0.3 $* | 0.19 $* |

| Mar-15-2025 | 0.3 $* | 0.81 $* |

| Feb-15-2025 | 0.95 $* | 0.46 $* |

| Jan-15-2025 | 0.58 $* | 0.93 $* |

Характеристики

specifications:

1.labor saved&easy operate

2.dripping process programmable

3.engergy saving&high out-put

4.English interface

5.high accuracy

6.suit for multicolors

with the automatic dispensing machine,we can make:

hot selling soft pvc car mats making machine is aplied for dispensing the label,trademark, key chain/ring/pad,zipper puller,USB drive,bracelet/wristband,watch strap/band,phone case/cover/holder,photo frame,cup wrap/mat,car mat,pen drive,glove,hand bar,miro injection,plug,rubber patch,shoe pad/sole,sleeve,trade mark,bake ware,kitchen ware,look ware,bowl,lid,look ware,neck lace,purse,gift,pad,ice tray,nipple,seal ring etc.

Machine Detail:

Mode | ZY-G082 |

Travel rangeX/Y/Z(mm) | 650/400/70 |

Speed X&Y & Z (mm/sec) | 0.1~600/400 |

Size | 1050×950×1600mm |

Weight(kg) | 450 |

Accuracy | 0.0001mm |

Repeat Accuracy | ±0.02 mm |

video mode | LCD |

Motor System | 400W servo-motor |

operation mode | Point-to-point/straight line segment |

Transmission Model | Imported precision screw + precision linear guide |

External Control Interface | RS232 |

Power | AC 220V 1200W |

Working Temperature | -5-40°C |

Features of pvc car mat dropping machine:

1.Labor saving, improve the production efficiency, one automatic dispensing machine can replace 4-6 skilled workers, one worker can operates several sets machines, greatly saving labors, some works can

do as dozens of workload, cut down the production phase. Solve the problems of labor shortage, more hard for practiced hand, hard manage, plant cover large, high input cost.

2.Special software, easy operation, multi-needles multi-colors, dropping accuracy. 8-12 colors(can extensible to 16 needles), multi needles can dispensing at the same time.

3.High precision, fast and liquidity walk in arc, three-dimensional. Coordinated system control, the precision can be 0.01mm, the products it produced is very stabilized, the products present of pass can over 99.9%, can improve the working efficiency 200-800%.

4.High stability: adopts CNC engraving machine rack construction technology, the materials adopts cast iron and granite, the rack will not be out of shape in 5-8 years, adopts origional imported screw rod, electrical equipment, moving stability and reliable, low failure rate.

5.Automatic dispensing machine operation guideline: to make the dispensing machine working in high efficiency, must do as follows:

(1) worker: using our dispensing machine, is to liberation the workers out of the boring and repeat dispensing training part.

(2) The workers main job is changed from dispensing and drying mold to control the machine production. The workers just need careful, strong sense of responsibility, the workers can take up their squires after training 2 or 3 days. But training to be a skilled dropping worker, it need 1-3 months.

6.Dispensing machine can undertake repeating pinpoint dispensing work. When it is in regular production, the dispensing needles do not connect with the molds, the distance to the molds is adjustable as you need, the dispensing speed is adjustable, dispensing quantity adjustable, do not need repair and clean the molds, at the same time replenish the bed materials, the thickness is the same, do not need repair.

7.Must bring a clean filter materials, if the materials is not clean, it will make the needle blocking, influence the speed. Just with suitable viscosity, string well-distributed, clean and healthful pvc materials, can make sure the dispensing machine continuation and efficiency production.

8.The molds need balance at four sides, the same thickness, clean and healthy. In a word, how to use the dispensing machine is depend on the operators, only make the good operate in each steps, the machine can express its largest advantage, so create highest profit.

JINYU PVC CAR MAT DROPPING ADVANTAGE:

Embedded system

Different from other mocker, jinyu always using the embedded systems, you can edit it on the mould picture or artwork on computer and then transfer the processing file to the CHIVANE machine to enable the running.

Professional software

Several edit tools available, with it, you can even processing difficult gift items by only drag mouse, the processing file can be save, copy and use again when next repeat orders.

The updated software can also calculate the whole needed work time for stitch, then you can have a idea in advance for its efficiency and delivery time.

High precision

Real micro-injection, thick or thin area was controled by the pressure and pause time of each needle, you can set and adjust it well enough on the edit software and then no need to wipe the the mould and deflashing at all.

Fluid system

Open fluid tank design, you can reloading the liquid material without shutting down the machine.

Advanced liquid control technology reliable advanced technology is applied to control liquid precisely and no need to maintain. It has obviously a advantage over the constantly flow change for syringe machine or high maintenance cost for rubber ring machine.

Application of pvc car mat dropping machine:

The pvc car mat dropping machine aplied for dispensing the bracelet, trademark, mobile phone case, mobile phone button, coil and speaker outerring etc. We can modify and customize carious dispensing machine as customer required, and add special software function for the machine.

samples of pvc products:

need more information,please contact me freely!