ZH-1800BFT автоматический герметический гофрированные аварии днища замка коробка для склеивания

- Категория: Post-Press Equipment >>>

- Поставщик: Wenzhou,Hoson,Printing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.63 $* | 0.27 $* |

| Aug-16-2025 | 0.37 $* | 0.48 $* |

| Jul-16-2025 | 0.37 $* | 0.88 $* |

| Jun-16-2025 | 0.15 $* | 0.19 $* |

| May-16-2025 | 0.83 $* | 0.21 $* |

| Apr-16-2025 | 0.52 $* | 0.72 $* |

| Mar-16-2025 | 0.32 $* | 0.77 $* |

| Feb-16-2025 | 0.31 $* | 0.28 $* |

| Jan-16-2025 | 0.50 $* | 0.1 $* |

Характеристики

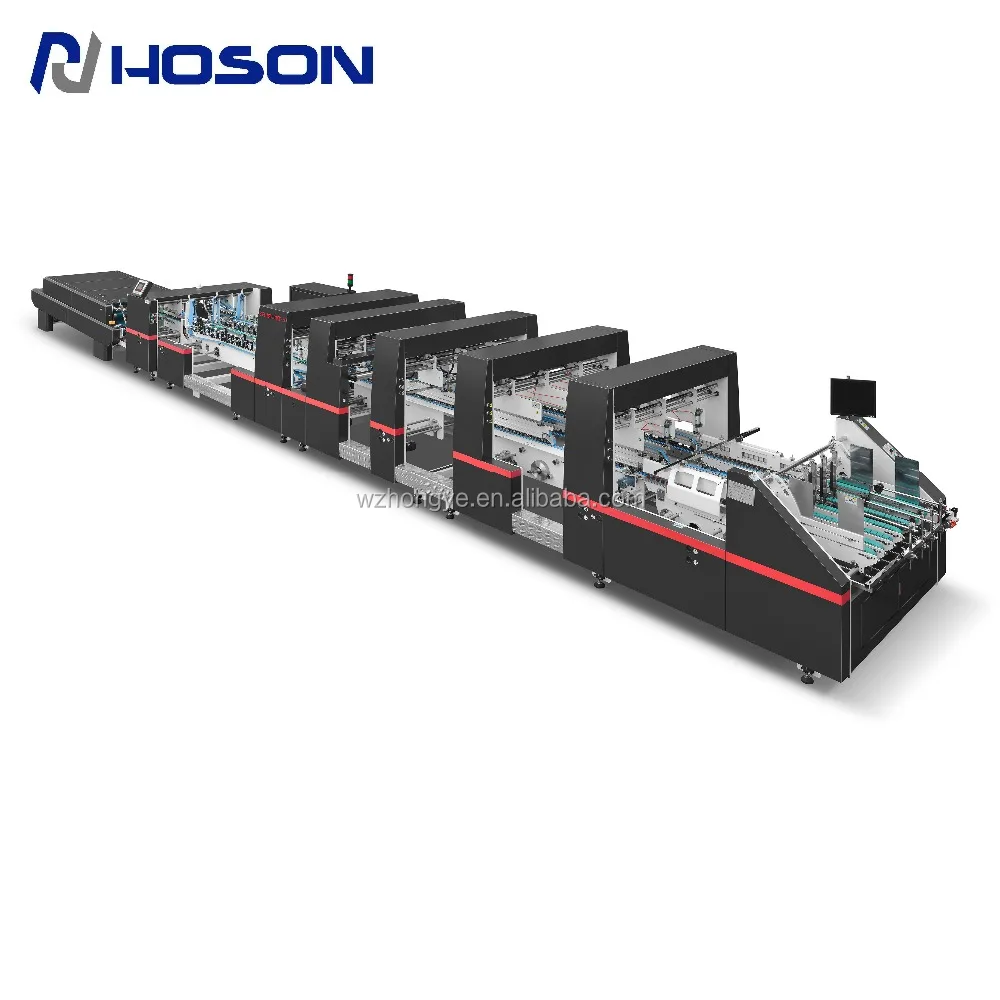

ZH-1800BFT Crash Lock Bottom Automatic Folder Gluer (Papeboar and corrugated)

1. Crash lock bottom box

2. Straight line box

3. Double walls box

Box

Box Type | Picture | A Max | A Min | B Max | B Min | C Max | C Min | D Max | D Min |

Crash-lock Bottom Box |

| 1450-500mm | 900-400mm | 300mm | 50mm | ||||

Straight Line box |  | 1600-350mm | 900-500mm |

|

| ||||

Double Walls Box |  | 1380mm | 900mm | 150mm | 850mm | ||||

Para.

1 | Line speed | 0-200m/min , Continuous adjustment |

2 | Usage paper | 350-800 g/ms, paperboard, E/B Flute |

3 | Box forming | Bottom-lock, straight line box, double walls box |

4 | Fold method | 1st folds 180°, 3rd folds 90°, 2nd & 4th folds 180° to form box. |

5 | Paper feeding | Automatic feeding, grinding unit |

6 | Electric Power | 22.0 KW |

7 | Dimension | 15.0*2.3*1.7m |

8 | Weight | 8700 kgs |

Detailed Photo

Features:

1) This machine is designed for Crash lock bottom box, straight line box and double walls box. In pre-folding part, the 1st fold at 90o, the 3rd fold at 90o. In the folding and forming part, the 2nd and 4th fold at 180o

2) It is equiped with good parts: Taiwan Motor, Schneider Inverter/PLC/Electric, Japanese Nitta Belts, Japanese Bearing, Germany Continental Timing Belts etc.

3) Two gluing unit: Top gluing unit for bottom gluing and lower gluing unit for side glue. Both of them supply line glue, to help the box sticked more firmly.

4) Equipped with PLC and touch screen system to make the operation more convenient. Out-put quantity/Speed/Counting etc. is able to be set by this system. A wireless remote controlled included in this machine to help the operation more easy. Counting is through photo-electric sensor&electromagnet kicking.

5) Pressing unit designed with Pneumatic system, which make the gluing more firmly and stable.

6) For Corrugated box (E flute), optional designed with correction unit that could help the paper running and folding in the aligning line.

7) Feeding is controlled by separated motor. Feeding belts can designed with draft design (belts with holes). Paper is usually feed by severa thick belts unde the help of vibration moto. Feeding is continuous, exact and autoamtic with this system.

8) Grinders are provided in both sides of machine, to make gluing more stable and firm.

9) An Electric adjustment system in this machine make it conveniently whne adjusting the space of carriers which usually based on the double-face tooth rods adjusting system

10) Germany HHS spraying system and Plasma device for optional.

HOSON welcome your inquiry.