Полностью автоматическая машина для производства бетонных блоков кирпичей укладывания

- Категория: Brick Making Machinery >>>

- Поставщик: Shandong,Gaotang,Huatong,Hydraulic,Pressure,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.32 $* | 0.33 $* |

| Aug-18-2025 | 0.56 $* | 0.85 $* |

| Jul-18-2025 | 0.37 $* | 0.88 $* |

| Jun-18-2025 | 0.59 $* | 0.2 $* |

| May-18-2025 | 0.58 $* | 0.48 $* |

| Apr-18-2025 | 0.57 $* | 0.91 $* |

| Mar-18-2025 | 0.37 $* | 0.67 $* |

| Feb-18-2025 | 0.82 $* | 0.99 $* |

| Jan-18-2025 | 0.40 $* | 0.51 $* |

Характеристики

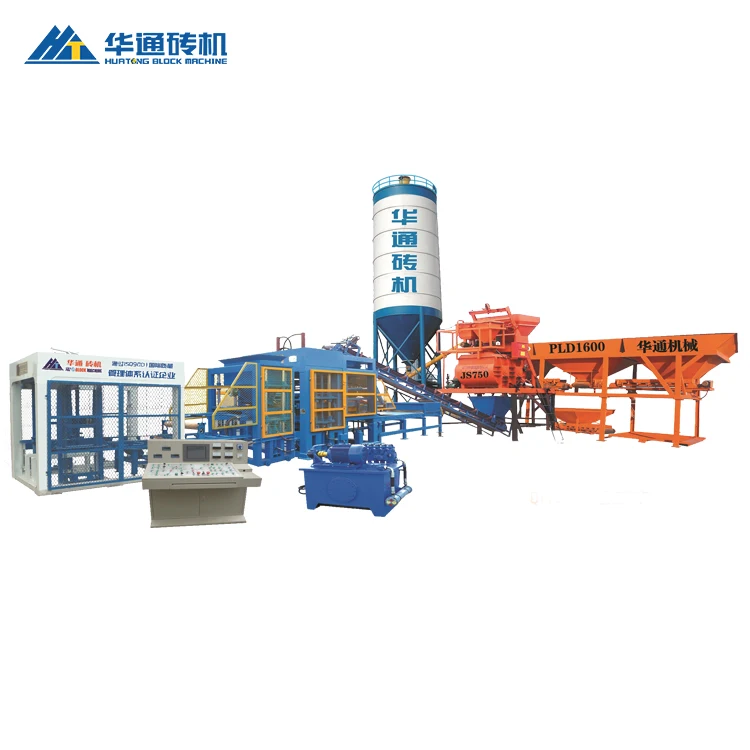

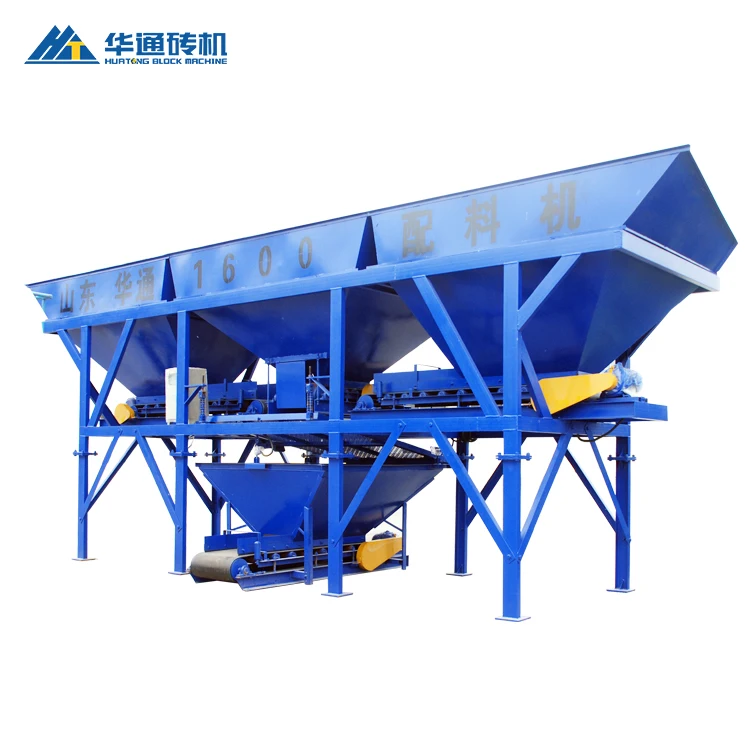

QT10-15Automatic Block Making Machine

New Condition and Concrete Brick Raw Material block making machine

specification

Main Technical Specifications | |

Standard | JC/T920-2003 |

Vibration Frequency | 3800 cycles/minute |

Vibration Pressure | 75KN |

Production/mould | Hollow block(390x190x190mm) 10Pics/mould |

Solid brick (240×115×53 mm) 48 Pics/mould | |

paver brick(200×100×60mm)27 Pics/mould | |

Cycle Time | 15-25seconds |

Production/day(8hours) | Hollow block (390×190×190 mm) 12000-17000Pics |

Solid brick (240×115×53mm) 90000-100000Pics | |

Paver brick (200×100×60 mm) 34000-45742Pics | |

Motor Power | 45Kw |

Water Consumption | 5-10T |

Number of workers | 7-10worker |

Space of Ground | 6600m2 |

Gross Weight | 16T |

Machine Dimension | 5400×2050×3050mm |

Main materials | Cement,crushed stone dust,gravel,sand,coal fly ash,iron/aluminium dust,crushed cinder and some industrial wastes |

Products of machine | Hollow blocks,Solid bricks,Pavers,Kurbstones,Slope blocks,slabs, interlock bricks and so on. |

This type of Block Making Machine has the following advantages

Performance and feature

Good design:The bnlance system adopts four-pole guarding way with long guide unit to ensure the exact movement of mould box and pressing head.Gear balance system can make pressing head and mould box move stably in the production.The way of concrete feeding is revolving,convective and compulsive to ensure block density and reduce feeding cycle.Gear driving mode of feeding is more steady.The way of feeder moving is two curved arms drived by two cylinders,which makes feeder move quickly,durablly,and steadly.Stacker is controled by frequency conversion to adjust speed.The movement of stacker is flexible and steady.

Vibration System:The vibration adopts frequency conversion technique.The assembly is oil immersed vibration.This improve high speed loading and makes concrete liquefied and air-outed.The five advantages is vibration assembly synchronization,soft starter,densify block,electric saving and quick moulding.

High automatic level:The machine is high automatic level and advanced design.It adopts international high computor technique to make machine and electric control system to be one part.Our technicians put fault diagnosis,problem alarming into computer by safty logic control.The screen will show fault and methods to client if there is some problems

Steady&Safe System :It adopts separation of high and low voltage electricity ,low voltage controls high voltage technique.This will solve problem of high voltage interfere and ensure gaining of exact signal.It is safe for people and machine .

Waste-Recycle:The raw materials could be sand,stones and so on .The blocks made by our machine is high tensity,low weight ,low cost The machine can realise immidiate stacking if raw materials is good without burning and steaming.

This machine value is higher than its price.You will earn back your cost in short time for its simple operation,advanced moulding,power saving and special production.

certificate

Based on customers idea,normally it's suitable for shipping.

SHANDONG HUATONG HYDRAULIC MACHINERY CO.,LTD,one of the best block making machine manufacturers in China,is located at Renhe Zone,Gaotang County,Shandong Province,China.And Gaotang is well known as water city and famous for its penmanship and paintings.

Huatong covers25000square meters with 8000 square meters construction area,possessing modern assembly line workshops and offices.There are all kinds of machine tools and heat treatment facilities.There are many senior engineers and management personnels

blocks made by our machine

Our Services

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of build factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick)

(3) 24 hours service

(4) Welcome to visit our factory and production line anytime

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side.

(2) Set up, fix,and operate

(3) Will not train the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time,keep well communication with each other.