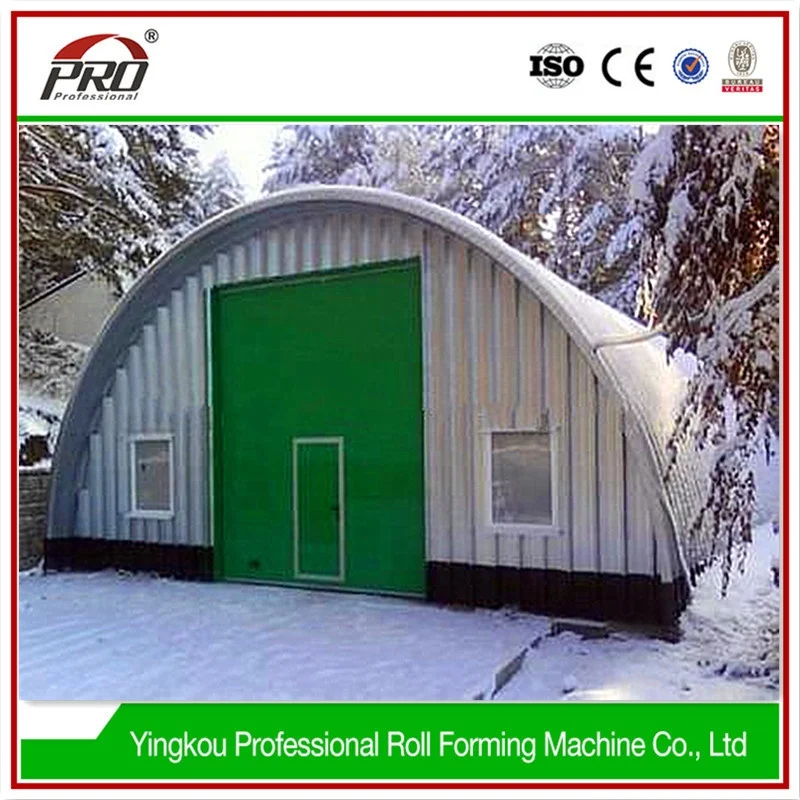

Длительный пролет кровельного листа б/у роликогибочная

- Категория: Машины для производства плитки >>>

- Поставщик: Yingkou,Professional,Roll,Forming,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 27370.97 $* | 28739.95 $* |

| Aug-19-2025 | 27140.73 $* | 28497.81 $* |

| Jul-19-2025 | 22770.80 $* | 23909.26 $* |

| Jun-19-2025 | 26680.91 $* | 28014.6 $* |

| May-19-2025 | 23230.75 $* | 24392.20 $* |

| Apr-19-2025 | 26220.17 $* | 27531.56 $* |

| Mar-19-2025 | 25990.96 $* | 27290.93 $* |

| Feb-19-2025 | 25760.85 $* | 27048.67 $* |

| Jan-19-2025 | 25530.30 $* | 26807.9 $* |

Характеристики

Technical Parameter of PRO-600-305

Technical Parameter of PRO-914-610

Related Production

Accessories List

Design Drawing

This is machine making 600-305 plate type. If you want machine making orther plate type, please tell us and we have professional team to design for you!

Rollers and Shafts Detail

Our roll forming machine’s rollers and shafts are connected with pin inside and screw outside, and with reinforcing design on both sides of rollers, which can fix the rollers and shafts tightly without deformation.

Main Machine Detail

Our roll forming machine includes 20 more wider rollers than other supplier’s machine, which can make the appearance of finished arch more beautiful.

Impeller Detail

10mm thickness smooth impeller, produced by CNC machining center.

Cutting Detail

Cutting material: Cr12 MoV, best and sharpest cutting material.

Adjust Span Detail

There is hand wheel with scale in bending part, for span height adjustment.

Pre-Sales Service

* Support inquiry and consult.

* Design machine you want.

* View our Factory.

* Provide the technical support.

During the Production

* We will send photo of making machine process detail every once in a while.

After-Sales Service

* Training how to use machine.

* Training how to make project.

* Engineers available to service machinery overseas.

FAQ

Payment

T/T( 30% by T/T in advance, the rest 70% to be paid by T/T after you inspect the machine in seller's factory before delivery )