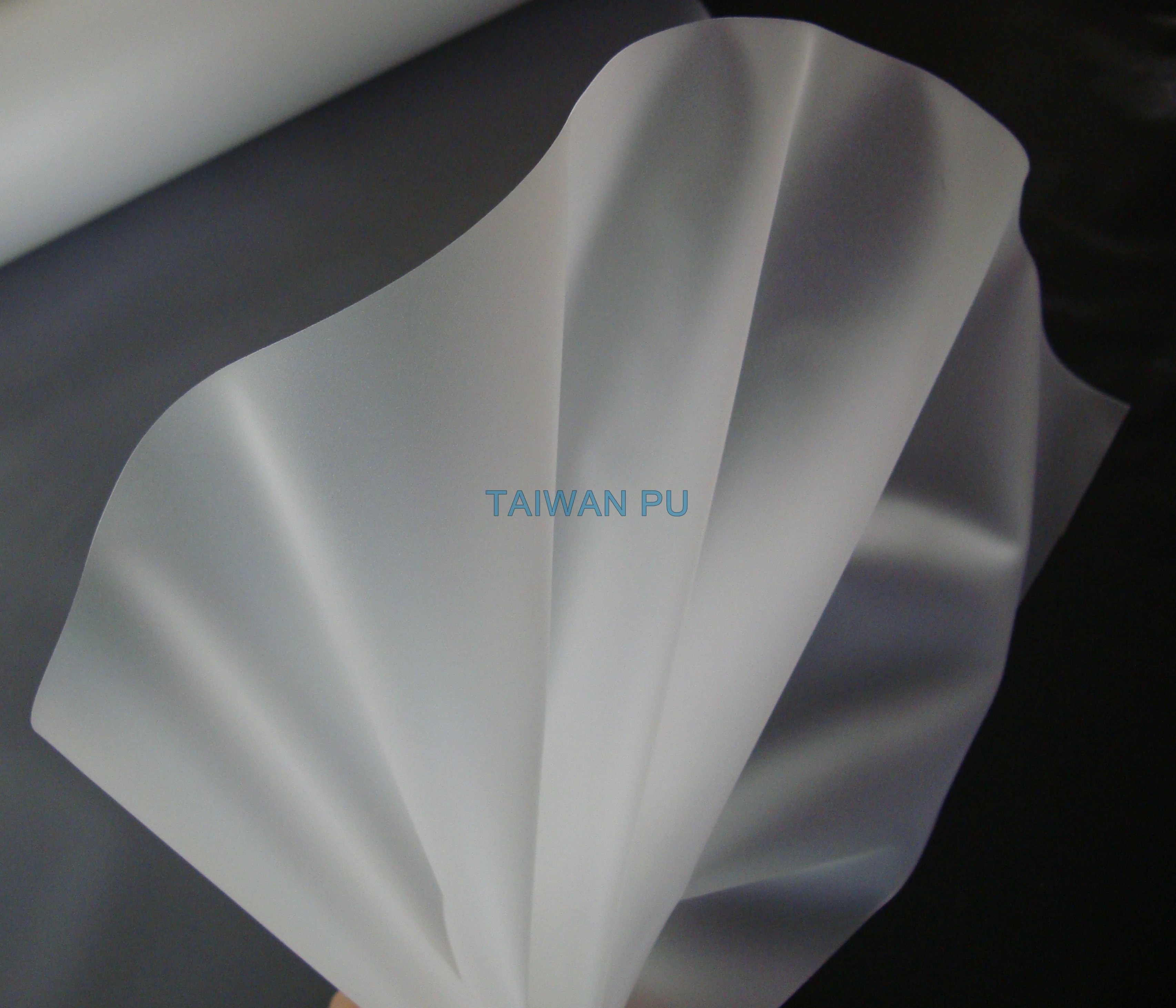

Отличный удлинение и прочность на растяжение ТПУ пленка

- Категория: ТПУ >>>

- Поставщик: TAIWAN,POLY-URETHANE,INDUSTRIAL,CO.,LTD.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.26 $* | 0.98 $* |

| Aug-18-2025 | 0.29 $* | 0.8 $* |

| Jul-18-2025 | 0.73 $* | 0.59 $* |

| Jun-18-2025 | 0.73 $* | 0.24 $* |

| May-18-2025 | 0.78 $* | 0.26 $* |

| Apr-18-2025 | 0.95 $* | 0.56 $* |

| Mar-18-2025 | 0.51 $* | 0.27 $* |

| Feb-18-2025 | 0.18 $* | 0.55 $* |

| Jan-18-2025 | 0.93 $* | 0.69 $* |

Характеристики

Product Description

Excellent Elongation and tensile strength TPU film in TPU

Advantage

- Excellent abrasion resistance

- High tear resistance

- Low temperature flexibility

High temperature resistance

Long-term durability

Various hardnesses

Environmentally friendly

Excellent Elongation and tensile strength

Application

TPU Film can use for medical, life preserver, outdoor, protective, shoes parts, ball, clothes, toys, infusion bed, water bags, industry and so on.

Specification

| Thickness | 0.1mm~2mm | Thickness Tolerance | ±10% |

| Width | 1000~1370mm | Surface Style | Glossy and Matte |

| Length | 100mm~1000mm (or more) | Color | Natural, Black, White, Red, Yellow, Transparent |

General Material Comparisons

| Polyurethane Films | Flexible Vinyl(PVC) | Low Density Polyethylene | Natural Rubber | Neoprene | ||

| Hardness(Shore A) | 75-97 | 40-90 | 90-95 | 30-95 | 40-95 | |

| Specific Gravity | 1.1~1.3 | 1.3~1.4 | 0.9~1.0 | 0.9~15 | 1.2 | |

| Elongation (%) | 400~600 | 200~400 | 200~600 | 100~800 | 100~700 | |

| Tensile (PSI) | 4~10 | 1~3 | 1~2 | 1~4 | 1~3 | |

| Low Temp. Flex | Excellent | Fair-Poor | Good | Excellent | Good | |

| Resistance to: | ||||||

| Abrasion | Excellent | Fair | Poor | Good | Good | |

| Tearing | Excellent | Fair | Poor | Good | Good | |

| Oil | Good | Fair | Poor | Good | Good | |

| Ozone | Excellent | Excellent | Excellent | Poor | Good | |

| Water | Good- Excellent | Good | Excellent | Good | Good | |

| Heat Sealable | Yes | Yes | Yes | NO | NO | |

| Heat Bond | Yes | Yes | Yes | NO | NO | |

| Solvent Bond | Yes | Yes | Yes | NO | NO | |

| Ultrasonic Bond | Yes | Yes | Yes | NO | NO | |

| Thermoformable | Yes | Yes | Yes | NO | NO | |

Physical Properties

| Polyester base | Polyether base | |

| Tensile Properties (D638) | ||

| Modulus @ 100% strain (psi) | 800 | 1000 |

| Modulus @ 300% strain (psi) | 1800 | 2000 |

| Modulus @ break (psi) | 7000 | 7000 |

| Modulus of elasticity up to 10% strain (psi) | 30 | 35 |

| Elongation @ break (%) | 400 | 450 |

| Set @ break (%) | 30 | 35 |

| Set @ 100% strain (%) | 3 | 5 |

| Tear Properties | ||

| Die C (D624) pli | 425 | 400 |

| Split (D 1938) pli | 400 | 375 |

| Abrasion Resistance | ||

| Mg. weight loss/1000 cycles1000 gmload, H18 (ASTM C501) (mg) | 70 | 30 |

| Maximum Service Temperature | ||

| Continuous (°C) | -40~105 | -52~95 |

| Compression Properties (shape factor=0.56) | ||

| Set, Method A, 22hrs.70°C(D395) (%) | 11 | 12 |

| Set, Method B, 22hrs.70°C(D395) (%) | 18 | 23 |

| Durometer (D2240) (Shore A) | 85 | 85 |

| Thermal Properties | ||

| Melting Point Range (°C) | 182~204 | 176~198 |

| Specific Gravity (D792) | 1.2 | 1.14 |

| Yield Factors | ||

| Square Feet/Pound/Ml. Thickness | 160.3 | 168.8 |

| Vapor Transmission Rates (E96) | ||

| (Inverted @ 22±2°C grams weight loss/100 sq. in./24hrs. @mil thickness) | ||

| Distilled Water | 2 | 2.1 |

| Superunleaded gasoline | 4.7 | 20 |

| Humid Again Resistance | Fair to poor | Excellent |

| (90% relative humidity at160°F/70°C) | ||

| Notice: These values are based on the test of our present laboratory test specimens. | ||

**More information, please access our website:

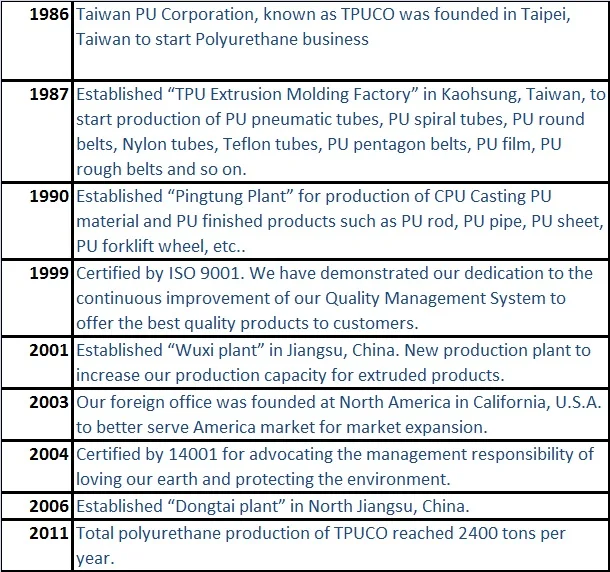

Company Information

Packaging & Shipping