Массивное отделочное средство для обработки поверхности хорошее качество металлическое удаления заусенцев

- Категория: Abrasives >>>

- Поставщик: Huzhou,Xingxing,Abrasive,Co.,Ltd.Huzhou,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 109.65 $* | 114.69 $* |

| Aug-17-2025 | 109.16 $* | 114.12 $* |

| Jul-17-2025 | 91.4 $* | 96.59 $* |

| Jun-17-2025 | 107.74 $* | 112.48 $* |

| May-17-2025 | 93.45 $* | 98.8 $* |

| Apr-17-2025 | 105.89 $* | 110.87 $* |

| Mar-17-2025 | 104.13 $* | 109.46 $* |

| Feb-17-2025 | 103.6 $* | 108.88 $* |

| Jan-17-2025 | 102.97 $* | 107.96 $* |

Характеристики

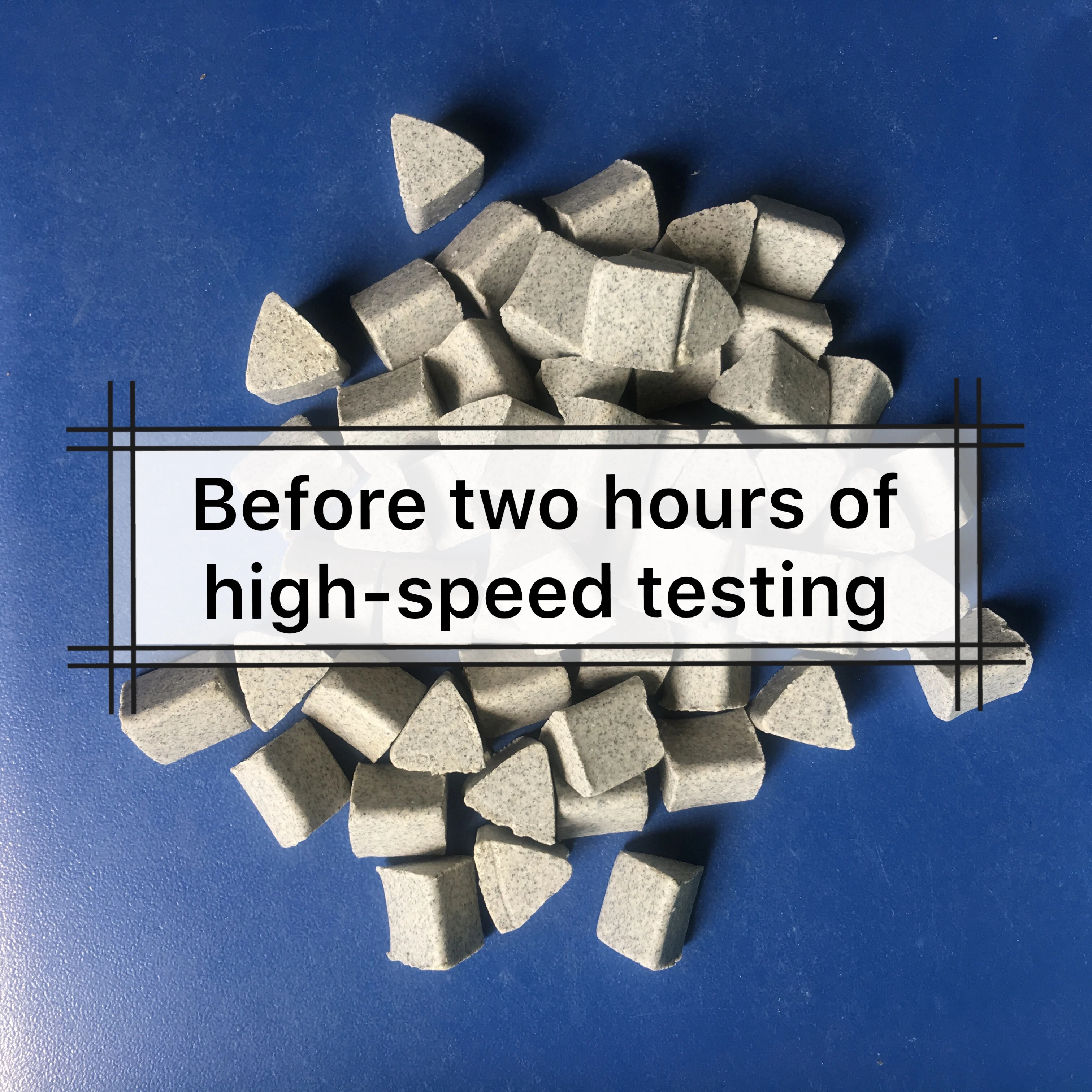

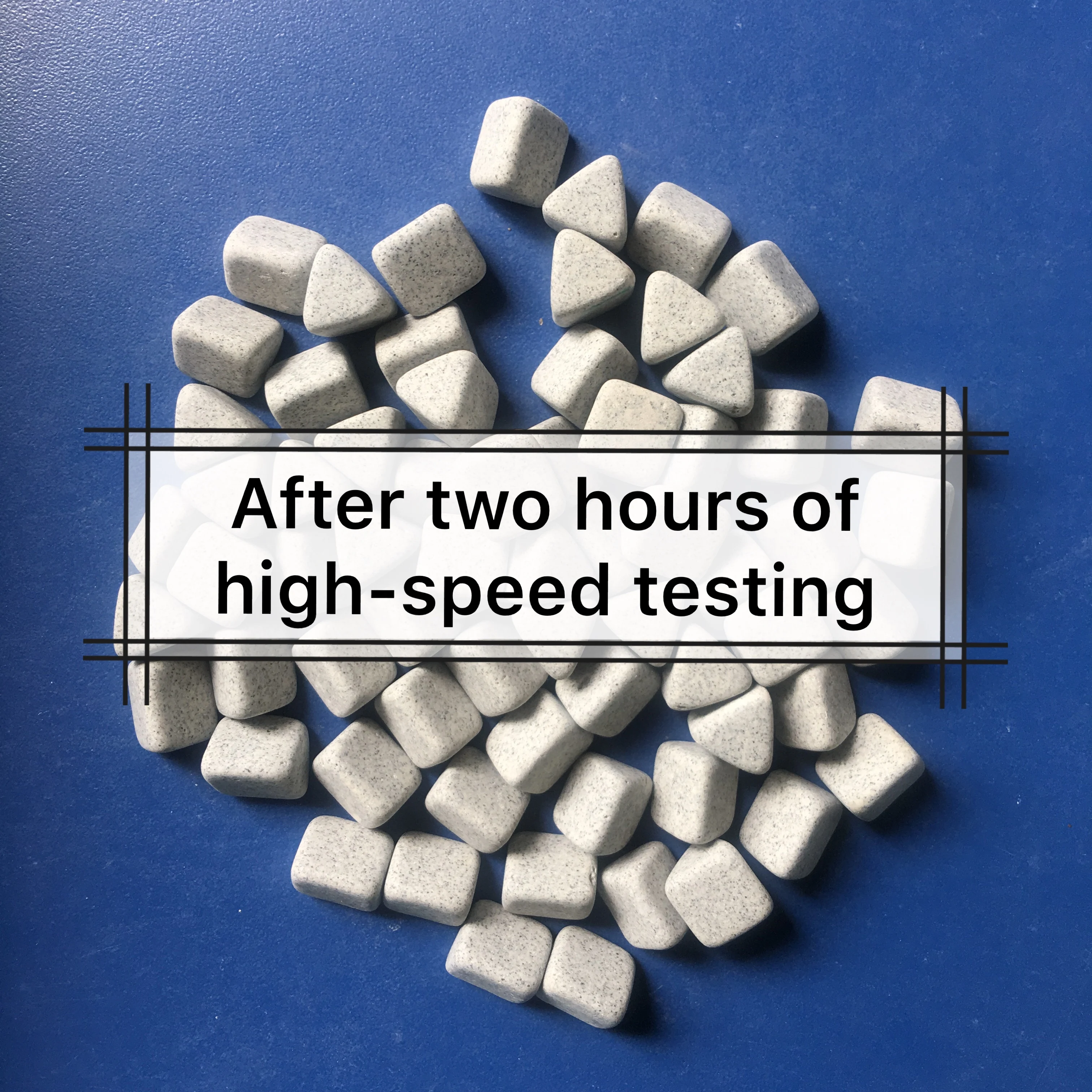

Different recipes are formulated for different industrial applications. Fast cutting, medium cutting, light cutting as well as slow-to-non cutting grade are the most common types.

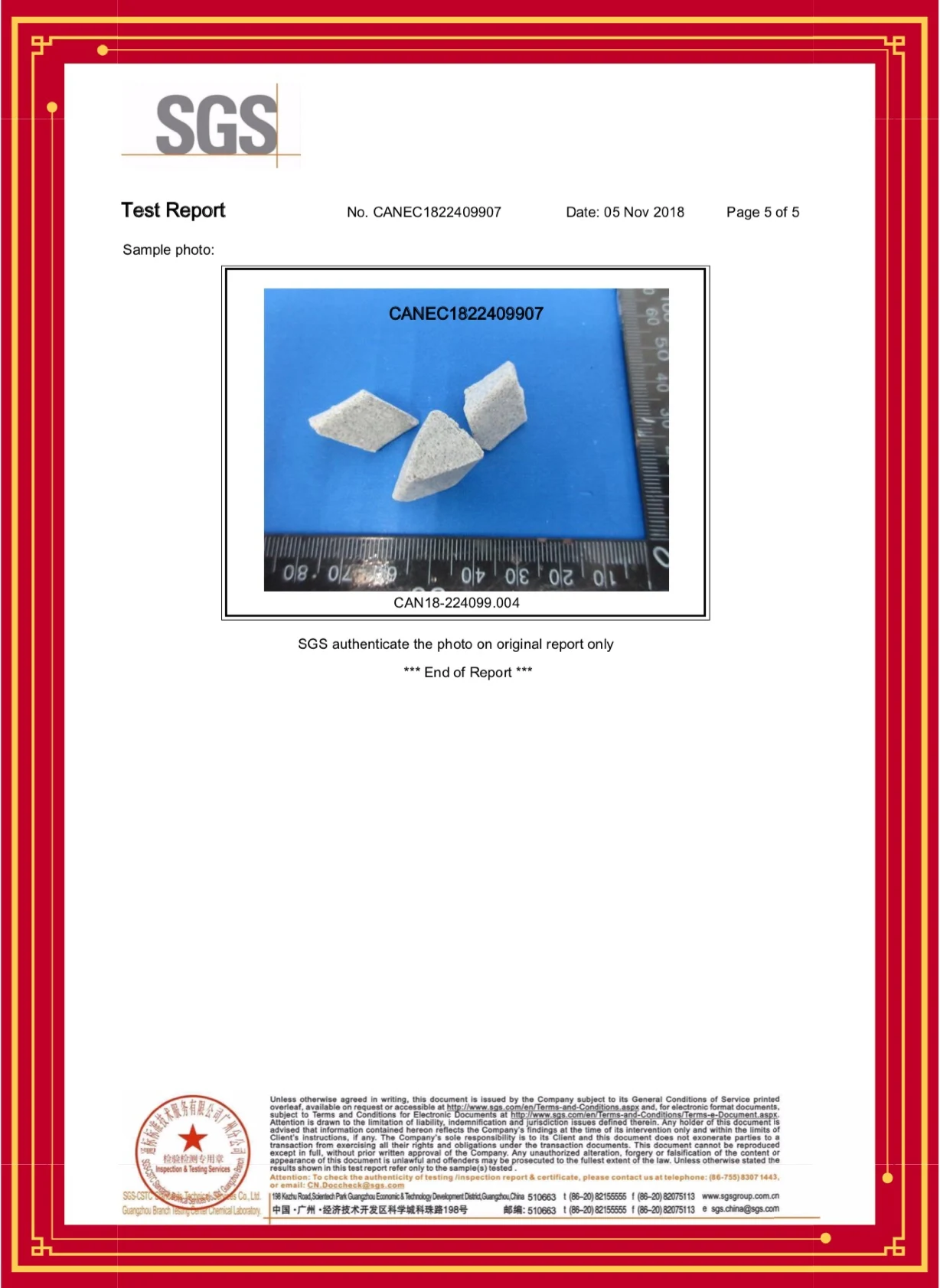

Ball | Straight/angle cut triangle | straight/angle cut cylinder | Cone | Tri-star/Angle Tri-star | Straight/angle cut ellipse |

1-5 | 3x3 4x4 | 2x4 3x6 | 20x20 | 6x6 | 8x3x8 |

6-10 | 5x5 6x6 | 5x10 6x12 | 30x30 | 10x10 | 10x5x10 |

11-15 16-20 | 8x8 10x10 12x12 15x15 20x20 25x25 | 8x15 10x15 12x25 15x25 | 40x40 | 15x15 20x20 | 15x7x15 25x10x25 |

21-25 | 30x30 35x35 40x40 45x45 | 16x30 20x40 35x40 | 22.23x9.53 28.58x9.53 | 28x15x28 |

2. Regularly introduce new products and new functions and technologies to users.

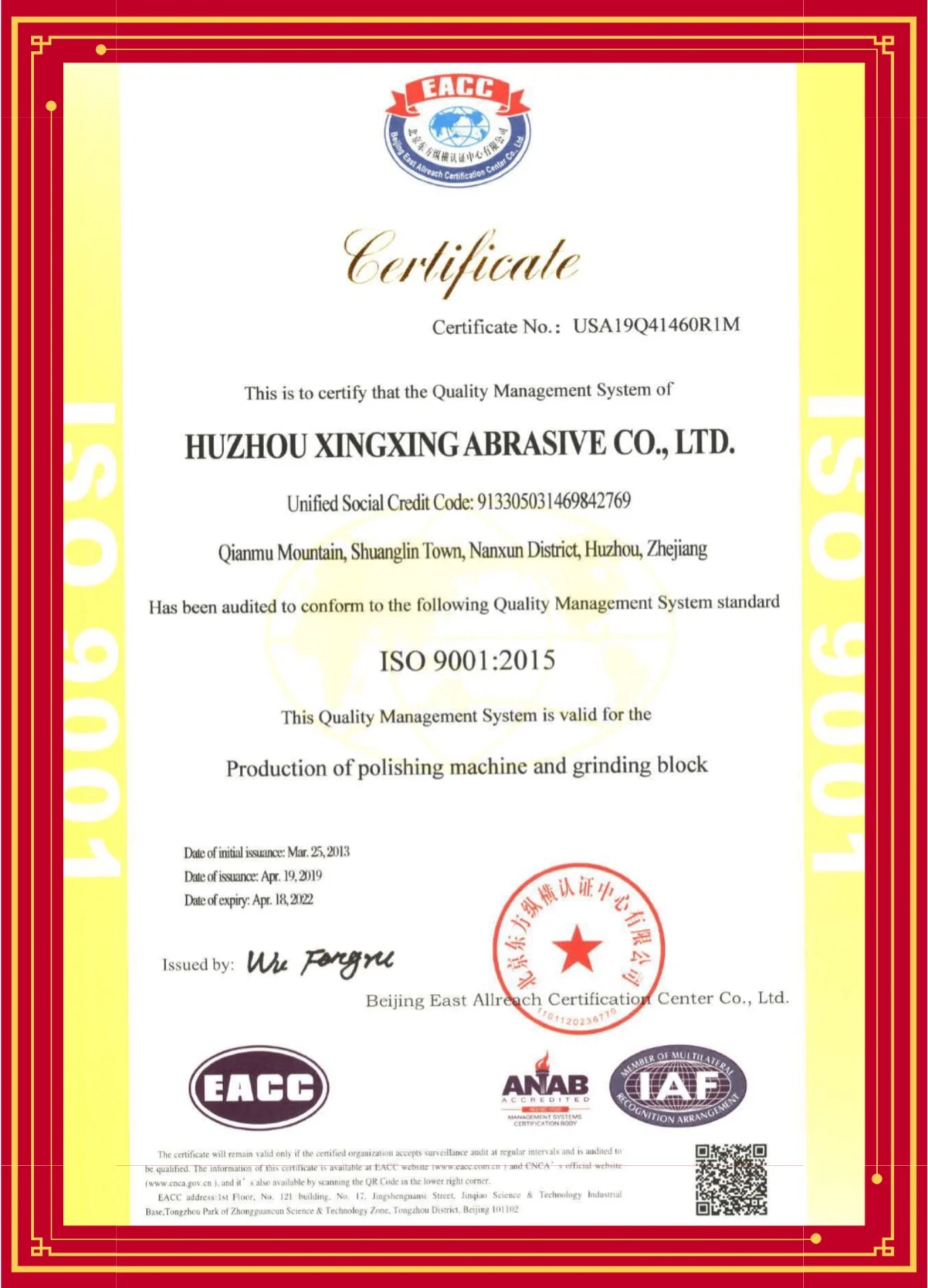

The company has been awarded province and municipal titled " Excellent Technology Advancement"

for several times. The company has set up a strict quality assurance system, it passed the ISO:

9001:2000 in 2004, and CE certification in 2008.

The company mainly has three production workshops for mass finishing machinery, mass finishing

media, and compound, which are integrated to offer our customers with complete mass finishing

solutions. The company has a variety of finishing machines available in five categories: Vibratory

finishing machine, Centrifugal barrel machine, Centrifugal disc machine, Rotating barrel machine,

and shot blasting machine.

There are three series of mass finishing medias as ceramic media, plastic media, special media, and

more than thousand specifications.

In addition, Xingxing Abrasive also supply 12 kinds of polishing compound for mass finishing solutions.

The mass finishing product serves every sector of modern industry, such as aviation, automobile,

motorcycle, engine, compressor, textile machinery, alloy metal, non-metal workparts,, magnetic

products, and decorations, etc

Our factory