Hrc55-65 AISI52100 100CR6 конический роликовый подшипник хромистой стали шарики для

- Категория: Bearing Balls >>>

- Поставщик: Ningyang,Xinxin,Stainless,Steel,Ball,Manufacture,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.47 $* | 0.76 $* |

| Aug-17-2025 | 0.73 $* | 0.32 $* |

| Jul-17-2025 | 0.61 $* | 0.67 $* |

| Jun-17-2025 | 0.92 $* | 0.24 $* |

| May-17-2025 | 0.61 $* | 0.82 $* |

| Apr-17-2025 | 0.84 $* | 0.62 $* |

| Mar-17-2025 | 0.89 $* | 0.10 $* |

| Feb-17-2025 | 0.63 $* | 0.10 $* |

| Jan-17-2025 | 0.16 $* | 0.88 $* |

Характеристики

hrc55-65 AISI52100 iso 3290 bearing steel balls for bearings

SPECIFICATION:

1)material: GB GCr15(AISI 52100, JIS SUJ-2, DIN 100Cr6)

2)Size: 0.5mm-80mm

3)Grade:G10-G1000

4)4)Hardness: HRC 61--66

5) Producing standard:GB308-2002

6) 6)Feature: Good wearing, excellent surface quality and high hardness.

7)Using:

(1). General industry for automobile, motorcycle, bicycle,manufacturing, special bearings & micro – ball for the electronics industry.

(2). High accuracy & low noise motor bearing& household

appliance bearings

(3). High - speed, low noise special bearing

(4). Ball valves for liquid and gas etc.

1)Material Comparison List

CHINA | USA | JAPAN | GERMANY | FRANCE | ENGLAND | ITALY |

GB | AISI | JIS | DIN | BS | BS | UNI |

GCr15 | 52100 | SUJ-2 | 100Cr6 | 100C5 | Si35534A99 | SKF3 |

chromium |

| 1.30% TO 1.60% |

carbon |

| .98% TO 1.05% |

manganese |

| 0.25% TO 0.45% |

silicon |

| 0.15% TO 0.35% |

phosphorous |

| 0.010% MAX. |

sulphur |

| 0.008% MAX. |

Heading:

In the first step, heading machines cut wire into short lengths and form it into spherical shapes between dies.

Deflashing:

The flash line, a ridge left by the forming dies, is removed as balls roll between heavy,cast iron plates.

Soft Grinding:

Similar to deflashing, except that a grinding stone is used to improve precision.

Heat-treating:

Carbon steel balls are next carburized and hardened. Heat treatment imparts the desired hardness and case depth.

Descaling:

This step removes the residues and by-products from the heat-treating process.

Hard Grinding:

Slow, meticulous grinding assures proper sizing and sphericity, with tolerances as closeas ±.0001".

Lapping:

Several proprietary lapping processes can bring balls to the requirements of ISO 3290 Grade10 - 48.

Finishing:

Proprietary chemical and mechanical processes give the balls their final micro-smoothed finish, for increased wear resistance and product longevity.

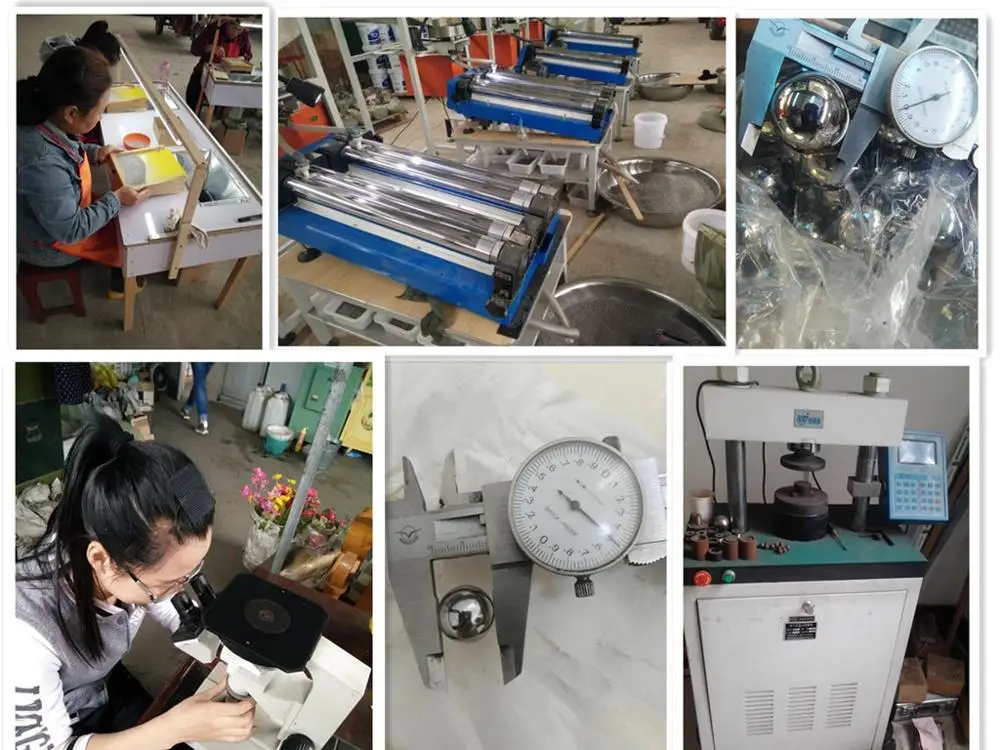

1. Ball chose by people

2. Ball select by machine

3. Ball test by Vernier calipe

4. check ball surface by magnifying glass

5. Ball test by three needle gauge

6. Ball test hardness by hardness tester

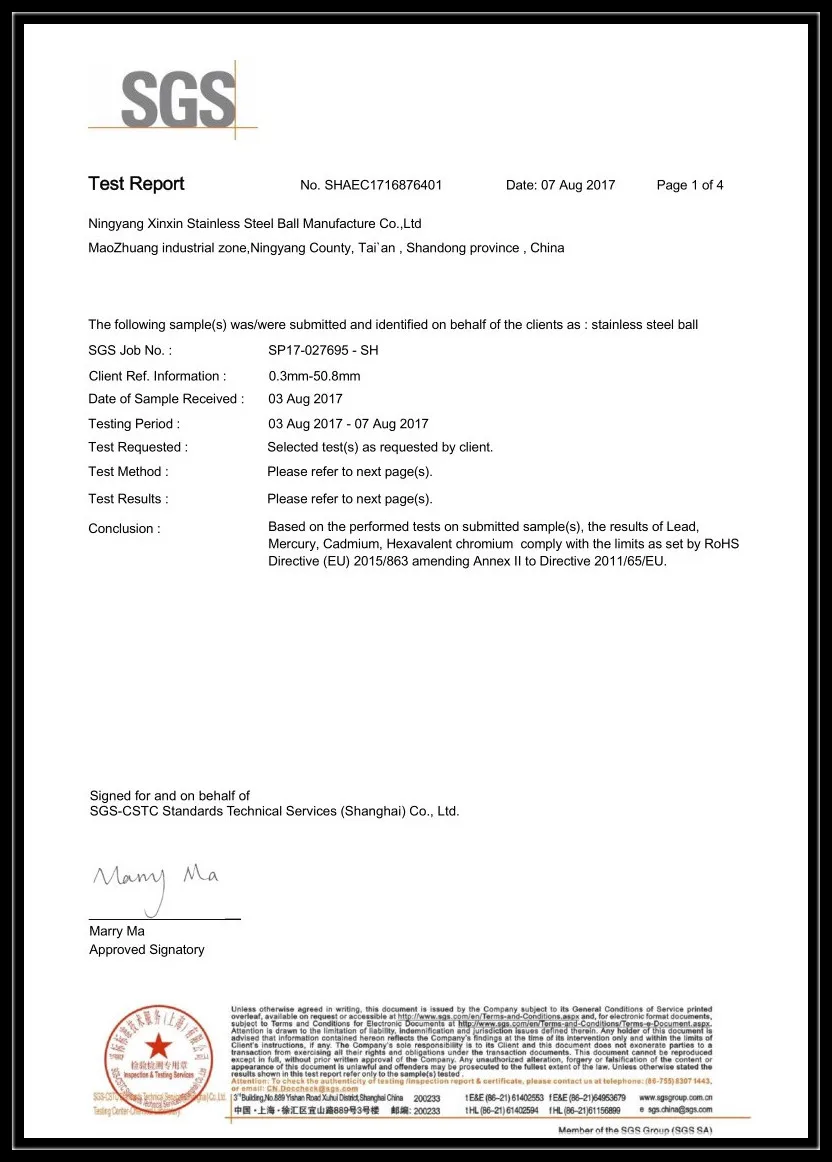

Our factory already get ISO

Package type : a, Steel drum packing

1) 250 kg per steel drum

2) 4 drums on one pallet

3) Drum with pallet size: 75*75*65cm

b, Carton package

1) 25 kg per carton , 36 cartons on one pallet

2) Carton size: 30*20*15

Glass ball ,plastic ball ,Ballcone ,Brass ball,Ceramic ball