Спиральная катушка машина для переплета

- Категория: Переплетные машины >>>

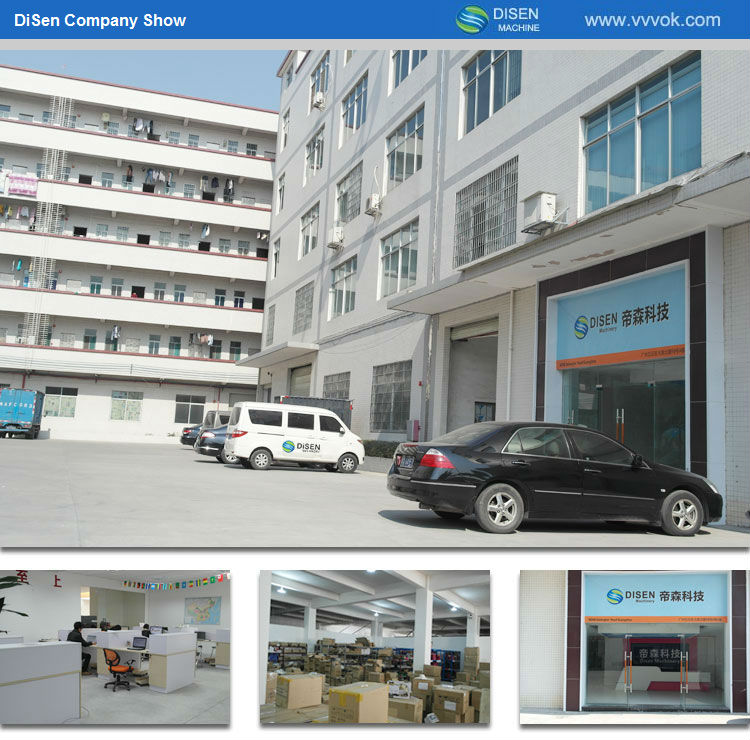

- Поставщик: Guangzhou,Disen,Electromechanical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 238.34 $* | 250.13 $* |

| Aug-19-2025 | 236.10 $* | 248.0 $* |

| Jul-19-2025 | 198.61 $* | 208.63 $* |

| Jun-19-2025 | 232.66 $* | 244.60 $* |

| May-19-2025 | 202.87 $* | 212.45 $* |

| Apr-19-2025 | 228.13 $* | 239.29 $* |

| Mar-19-2025 | 226.33 $* | 237.86 $* |

| Feb-19-2025 | 224.87 $* | 235.74 $* |

| Jan-19-2025 | 222.46 $* | 233.11 $* |

Характеристики

Product Name: CC2916 Coil & Comb 2-in-1 funcational binding machine

|

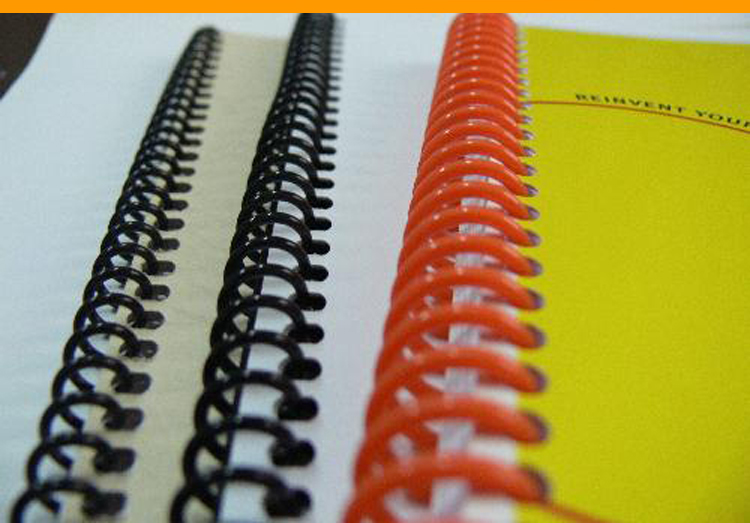

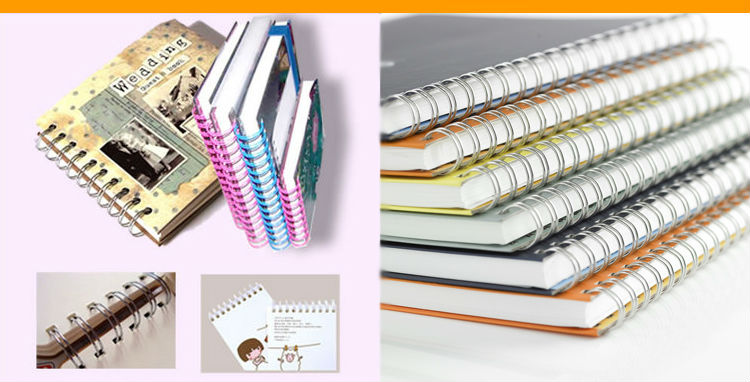

Spiral coil binding machine price Comb type rubber ring bookbinding machine comb binding machine is all in the binding machine, use cost a minimum, simple, easy disassembly, repeated binding; is suitable for small office or the general meeting document binding, and small text printed agency. A binding machine has two kinds of binding method, this is also one of its major features. Comb binding is a loose leaf type, add and delete pages conveniently, can realize the text 360 degree flip, ring diameter size, text binding determines the thickness, the binding mode as the rubber ring size, color and the colour of the cover a larger choice, so the match results also differ in thousands, bind the product elegant, unique style. Wire binding machine is generally divided into 2:1 (21 holes) and 3:1 (34 holes) two. The 3:1 wire binding machine binding effect is more delicate, suitable for text binding thin, suitable for Design Institute, General Planning Bureau or small and medium-sized printing center; type 2:1 is suitable for binding thick documents.

Spiral coil binding machine price 1, install the handle: the box with handle sleeve into the binding machine right axis position (Note: handle working angle), locking screws. 2, paper consumption: according to the various models specification paper quantity to decide, not excessive. Otherwise it may lead to the following adverse circumstances: The handle is not under pressure, wear paper barrier, cannot penetrate. The margin is not balanced, prone to the edge of the paper roll angle. 3, paper margins of adjustment, the principle is: according to the pull ring diameter size determines the margin size. The method is: use the adjustment screw (installed in the binding machine behind) to achieve the purpose of adjusting the scale of the margin. The rule is: pull ring diameter, paper margins up, pull ring diameter is small, small paper margins. 4, the perforating operation method: The paper organized, close to the positioning block, the paper into the machine in parallel, the top place. The paper is pressed by the left hand, right hand holding the handle, press down to the blade through the paper, and then lift up the handle. Hands steady will lay the paper out, such as the emergence of paper hanging phenomenon, repetition will handle pressure, then go to can be out of paper. Note: This article from the My12345 collection, reprint please indicate the source. 5, pull method of binding ring: According to the amount of paper, pull the ring size of different sizes, the handle slowly push pull ring to open, and then move the paper hole into the pull ring, the handle slowly pulled back, let pull ring teeth inserting paper hole, the handle is pulled in place, tighten the pull ring, binding will be installed the.

Spiral coil binding machine price •Made of better structural section, the binder is solid, steady, durable, and pleasing to the eye. •Being controlled wholly by industrial grade chip with liquid crystal display, having human feeling style interface design with trouble prompt, the binder is simple and convenient for operation, and easy to be learnt and grasped. •The binder’s mechanism is set up with fully automatic device, being extremely convenient for sorting out book core, automatically clamping book, saving time and manpower. •Sun cutter, grooving cutter etc. main components are made of imported materials to ensure the stability of milling back and grooving, and the effect of wrapping books. •Backfeed in real time of circuit sine curve heating and glue trough made of all-aluminum ensure collosol to be uniform. •Vertical clamping-surface mechanism makes binding book back to be straight, and edges and corners to be distinct, and the words on book back to be precise. •Fully-opening surface-setting structure makes taking book on surface-setting to be extremely convenient with great facility. 1. Humanization designs such as LCD display, automation, error hint function, make it quite easy to operate. 2. Import silent cylinder, reliable power, stable, pressure display, convenient adjustment. .The opening assembling style makes the operation really convenient. 3. The main import components such as sun milling cutter, necking tool etc .stabilize the machine, and increase the life expectancy. 4. This machine has whole frame mechanism, Smooth shape; Elegant, beautiful aspect, and opening assemble style. We are professional finishing equipment manuafcturer since 1994. We believe our products will provide you with great business benefits and advantage. Our Faith: Honesty based quality first and service oriented! Our Aim: To help agents and distributors create as much benefit as we can! To help Customer do excellent jobs with our machines! If you have any inquiry, please dont hesitate to contact DiSen Machine. We will reply you at the first time as we can.

|