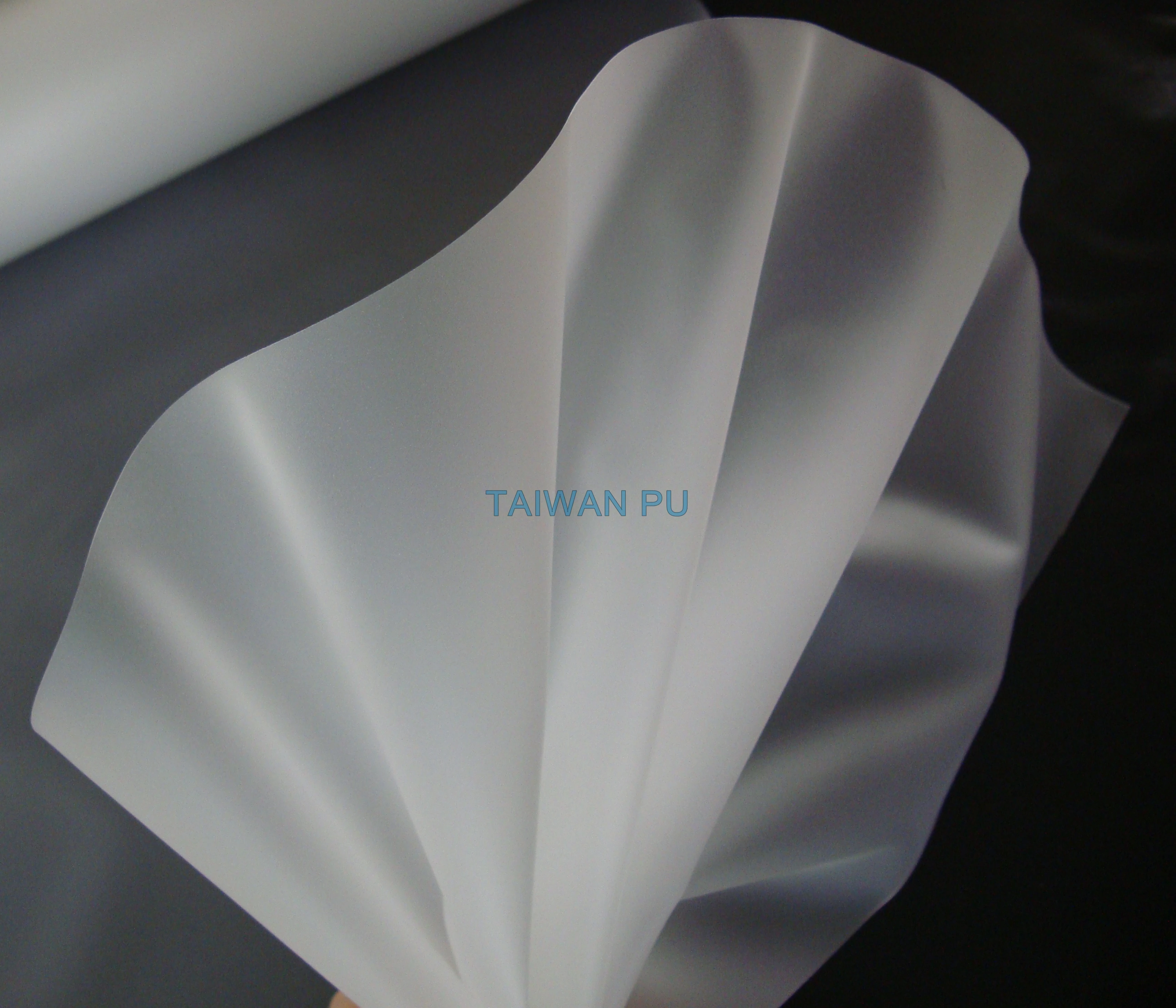

Термопластичная термопластичная пленка из ТПУ с высокой

- Категория: TPU >>>

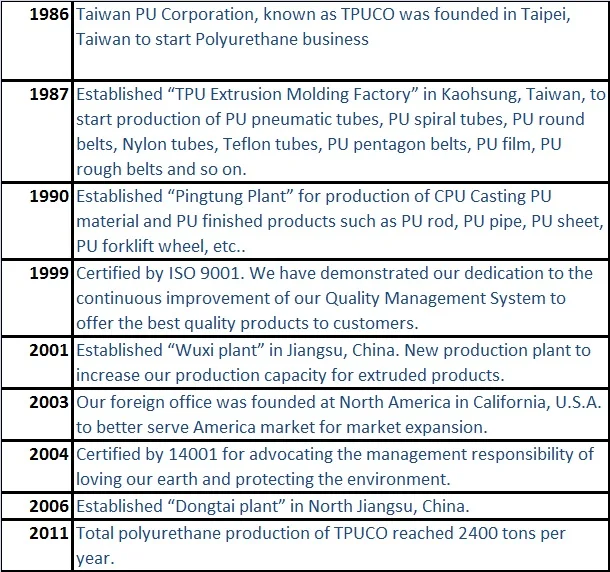

- Поставщик: TAIWAN,POLY-URETHANE,INDUSTRIAL,CO.,LTD.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.87 $* | 0.61 $* |

| Aug-17-2025 | 0.81 $* | 0.21 $* |

| Jul-17-2025 | 0.93 $* | 0.86 $* |

| Jun-17-2025 | 0.3 $* | 0.38 $* |

| May-17-2025 | 0.13 $* | 0.61 $* |

| Apr-17-2025 | 0.60 $* | 0.55 $* |

| Mar-17-2025 | 0.30 $* | 0.94 $* |

| Feb-17-2025 | 0.98 $* | 0.77 $* |

| Jan-17-2025 | 0.8 $* | 0.19 $* |

Характеристики

Product Description

High temperature resistance hermoplastic TPU Film

Advatage

- Excellent abrasion resistance

- High tear resistance

- Low temperature flexibility

- High temperature resistance

- Excellent Elongation and tensile strength

- Environmentally friendly

- Various hardnesses

- Long-term durability

Application

For medical, life preserver, outdoor, protective, shoes parts, ball, clothes, toys, infusion bed, water bags, industry and so on.

Specification

| Thickness | 0.1mm~2mm | Thickness Tolerance | ±10% |

| Width | 1000~1370mm | Surface Style | Glossy and Matte |

| Length | 100mm~1000mm (or more) | Color | Natural, Black, White, Red, Yellow, Transparent |

General Material Comparisons

| JUYONA Polyurethane Films | Flexible Vinyl(PVC) | Low Density Polyethylene | Natural Rubber | Neoprene | ||

| Hardness(Shore A) | 75-97 | 40-90 | 90-95 | 30-95 | 40-95 | |

| Specific Gravity | 1.1~1.3 | 1.3~1.4 | 0.9~1.0 | 0.9~15 | 1.2 | |

| Elongation (%) | 400~600 | 200~400 | 200~600 | 100~800 | 100~700 | |

| Tensile (PSI) | 4~10 | 1~3 | 1~2 | 1~4 | 1~3 | |

| Low Temp. Flex | Excellent | Fair-Poor | Good | Excellent | Good | |

| Resistance to: | ||||||

| Abrasion | Excellent | Fair | Poor | Good | Good | |

| Tearing | Excellent | Fair | Poor | Good | Good | |

| Oil | Good | Fair | Poor | Good | Good | |

| Ozone | Excellent | Excellent | Excellent | Poor | Good | |

| Water | Good- Excellent | Good | Excellent | Good | Good | |

| Heat Sealable | Yes | Yes | Yes | NO | NO | |

| Heat Bond | Yes | Yes | Yes | NO | NO | |

| Solvent Bond | Yes | Yes | Yes | NO | NO | |

| Ultrasonic Bond | Yes | Yes | Yes | NO | NO | |

| Thermoformable | Yes | Yes | Yes | NO | NO | |

Physical Properties

| Polyester base | Polyether base | |

| Tensile Properties (D638) | ||

| Modulus @ 100% strain (psi) | 800 | 1000 |

| Modulus @ 300% strain (psi) | 1800 | 2000 |

| Modulus @ break (psi) | 7000 | 7000 |

| Modulus of elasticity up to 10% strain (psi) | 30 | 35 |

| Elongation @ break (%) | 400 | 450 |

| Set @ break (%) | 30 | 35 |

| Set @ 100% strain (%) | 3 | 5 |

| Tear Properties | ||

| Die C (D624) pli | 425 | 400 |

| Split (D 1938) pli | 400 | 375 |

| Abrasion Resistance | ||

| Mg. weight loss/1000 cycles1000 gmload, H18 (ASTM C501) (mg) | 70 | 30 |

| Maximum Service Temperature | ||

| Continuous (°C) | -40~105 | -52~95 |

| Compression Properties (shape factor=0.56) | ||

| Set, Method A, 22hrs.70°C(D395) (%) | 11 | 12 |

| Set, Method B, 22hrs.70°C(D395) (%) | 18 | 23 |

| Durometer (D2240) (Shore A) | 85 | 85 |

| Thermal Properties | ||

| Melting Point Range (°C) | 182~204 | 176~198 |

| Specific Gravity (D792) | 1.2 | 1.14 |

| Yield Factors | ||

| Square Feet/Pound/Ml. Thickness | 160.3 | 168.8 |

| Vapor Transmission Rates (E96) | ||

| (Inverted @ 22±2°C grams weight loss/100 sq. in./24hrs. @mil thickness) | ||

| Distilled Water | 2 | 2.1 |

| Superunleaded gasoline | 4.7 | 20 |

| Humid Again Resistance | Fair to poor | Excellent |

| (90% relative humidity at160°F/70°C) | ||

| Notice: These values are based on the test of our present laboratory test specimens. | ||

**More information, please access our website:

https://www.taiwanpu.com/productInfo/PU%EF%BC%8BFilm/PU%EF%BC%8BFilm

Company Information

Packaging & Shipping