Профессиональный Производитель Силиконовых

- Категория: Пресс-формы >>>

- Поставщик: INTERTECH,MACHINERY,INCORPORATION

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.58 $* | 0.26 $* |

| Aug-19-2025 | 0.41 $* | 0.30 $* |

| Jul-19-2025 | 0.86 $* | 0.47 $* |

| Jun-19-2025 | 0.16 $* | 0.45 $* |

| May-19-2025 | 0.8 $* | 0.76 $* |

| Apr-19-2025 | 0.54 $* | 0.88 $* |

| Mar-19-2025 | 0.96 $* | 0.90 $* |

| Feb-19-2025 | 0.36 $* | 0.60 $* |

| Jan-19-2025 | 0.51 $* | 0.95 $* |

Характеристики

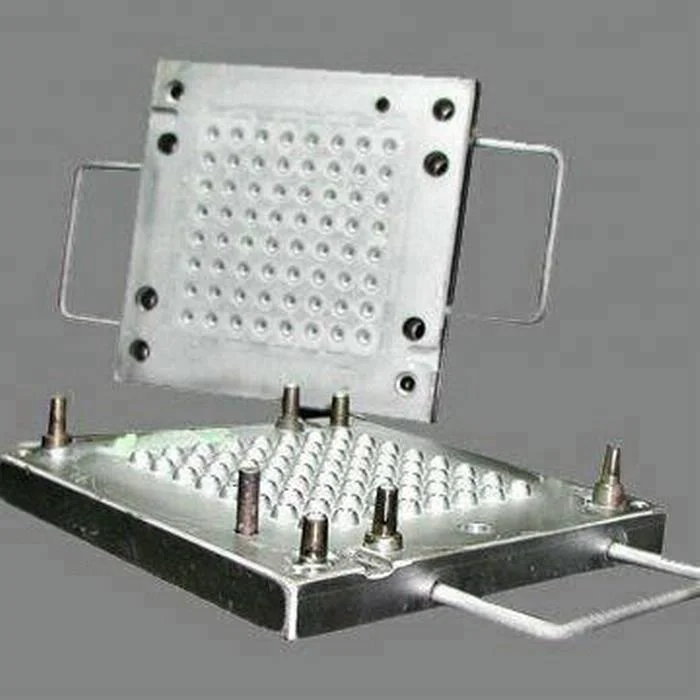

Professional manufacturer making plastic moulding silicone mold making

Intertech is a professional compression mold, rubber mold, precision compression mold,compression moulding services Supplier. Find more compression mold, rubber mold, compression moulding services information here or contact us for full service.

Intertech's silicone rubber mold are widely used in industries that span automotive, defense, sporting goods, medical devices and consumer products.

Silicone Rubber molding are used in industries that span automotive, defense, sporting goods, medical devices and consumer products. Liquid silicone rubber is usually made from low-viscosity, two-component materials.

-Capable to making silicone rubber molds in hot compression way or injection way.

-Mold cavity and mold size can be discussed upon your own requirements.

-Produced from SGS, approved silicone rubber and LSR materials.

- We usually use silicone rubber in the 40 to 70 shore A depending on customized requirements.

-Supply with minimized flash free & mark free molded silicone products.

- Available in dealing with OEM manufacturing, ODM manufacturing, customized production, contract manufacturing for silicone rubber mold & molding projects in Taiwan.

Silicone parts mold and molding application examples : Our mold development for silicone has a wide range of product application lines as such : ear plug, label, pad, gasket, protective frame, mobile phone protective cover, keypad, silicone rubber cord, check valve …etc.

*All Mold images are for demonstrations , we make Customized mold

Please send us all your project detail to us, so that we can study and send you our report.

-------------- Welcome your inquiry ! --------------

We are Alibaba SGS Verified Supplier

See more : https://intertech.en.alibaba.com/company_profile.html?spm=a2700.icbuShop.88.155.46632350V7bjiT

Quality Management Process

we check mold steel hardness and size precision. We test the mold and measure the parts and discuss all the time with customer with good report.

Dimension checking report

All sizes of mold and products are strict checked by our professional engineers in shop

Precision checking

For each time of mold testing, we do key dimensional check as per customer's request.

For each time of mold testing, we do key dimensional check as per customer's request.

Testing Machinery

1. Push-Pull Gage

2. STEREO MICROSCOPES

3. Optical Micro image Measurers

4. Profile Projectors

Mold Making Machine Equipment

1. EDM 2. Lathing machine

3. Milling Machine 4. Grinding machine

5. Drilling Machine 6. Band saw

7. 3D Printer 8. CNC Lathing

The most important service is we accept custom designed orders. As long as you offer the … Parts 2D, 3D, SAMPLE, PHOTO OF YOUR DESIGN and state clearly the mold cavity number, mold steel grade and required product quantity and material, then, we can quote our best price to you. Sample order is available after our discussion!

Product Name | Professional manufacturer making plastic moulding |

Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30% |

Mold Structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Surface Finish: | Texture (MT standard), high gloss polishing, Mirror finish etc |

Cavity / Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Mold Lead Time: | T1, 20~50 days, parts measurement report (upon required). |

Annual Output | 250 sets of mold |

Mold Steel Advantage

100% German & Japan Mold Steel !

Intel' Steel Certificate Guarantee !

Finer Even Steel Density Composed Steel!

Only With Assured Steel Hardness!

Finer Machining Way Benefit

Only With Assured Steel Hardness

Assured Hardness Certainly Needs

More Detailed & Finer Machining!

Finer Machining Consumes a lot CUTTER&TIME

But by doing above, it brings HIGH MOLD

QUALITY VALUE! !

High Mold Quality Value

You get high quality mold because it takes us

more time & finer machining process in between.

You get reliable assured consistency in

Duplicating the same product every time !

Simple Maintenance, 24hrs Running Mold,

Money Making Investment !