Индия Австралия Канада для угля гипса поролонового железа Экструзионное Оборудование Для Брикетирования на

- Категория: Металлургическое оборудование >>>

- Поставщик: Zhengzhou,Kehua,Industrial,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.28 $* | 0.78 $* |

| Aug-16-2025 | 0.92 $* | 0.97 $* |

| Jul-16-2025 | 0.6 $* | 0.49 $* |

| Jun-16-2025 | 0.80 $* | 0.35 $* |

| May-16-2025 | 0.37 $* | 0.21 $* |

| Apr-16-2025 | 0.41 $* | 0.9 $* |

| Mar-16-2025 | 0.10 $* | 0.77 $* |

| Feb-16-2025 | 0.16 $* | 0.83 $* |

| Jan-16-2025 | 0.67 $* | 0.29 $* |

Характеристики

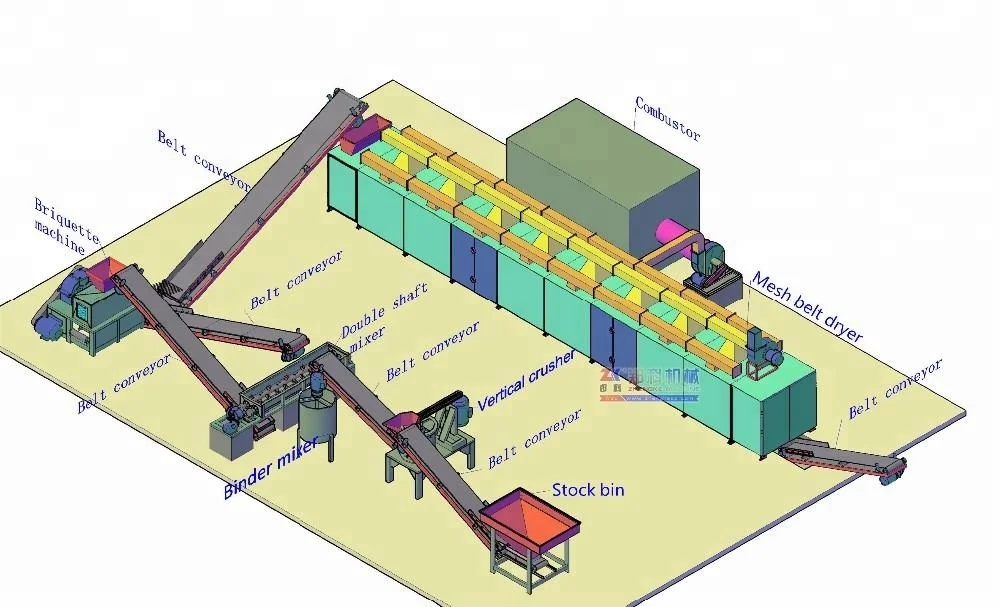

India, Australia, Canada for coal, charcoal, sponge iron briquette extrusion equipment for sale

Compacting your powder into briquette or producing granules with an extrusion equipment can make both you and your customers happy. The briquettes and granules are easier to handle than powders — they’re much less dusty, don’t segregate by size, shape, or density, and provide several other benefits as well.

Roll compaction is a form of high-pressure agglomeration. The method requires an extrusion equipment, which exerts mechanical pressure on a powder or other dry bulk material as it’s forced between two counter-rotating rolls.

Extrusion equipment is widely used for mineral powders, metal powders, chemical powders, biomass powders, etc. Thus, extrusion equipment is widely used in many industries, such as metallurgy, chemistry, refractory materials, energy, heating, transportation, etc. Final products could be round, oval, oblate, pillow, square, etc.

Request for raw materials:

Size: It's better to be less than 3mm. If not, crusher is needed.

Uniformity: Mixer may be needed to make materials homogeneous.

Moisture content: 9-15%. If higher than this, rotary dryer is needed.

We could provide customized service for clients:

Binder: Professional advice for you. Organic and inorganic binder: starch, molasses, pitch, asphalt, sodium silicate, gypsum, magnesia, etc.

Hydraulic system: Hydraulic system could supply higher, stable pressure and protect machine from the damage of impurities entrained in the raw materials.

Feeding system: According to the property of raw materials, gravity feeder or force-feeder is equipped.

Dry/wet press: Some materials require no binder added. In this case, dry press is necessary.

Size and shape: We can design the pockets on the surface of roller to meet the request for size, shape, capacity.

Zhengke is not only an equipment manufacturer, but also thermal solution and briquette solution provider. With an experience of 16 years, we have serviced both domestic and international clients with rotary dryer and briquette machine. Headquarter in Gongyi, branches in Shanghai and Zhengzhou, now we are expanding business rapidly. We are confident in ourselves to cooperate with clients from different countries and regions.

| Model | Roller diameter (mm) | Capacity (t/h) | Power (kw) | Size and shape |

| ZKBM290 | 290 | 1-3 | 5.5 | customized |

| ZKBM360 | 360 | 4-6 | 11/15 | customized |

| ZKBM430 | 430 | 6-8 | 18.5 | customized |

| ZKBM500 | 500 | 8-12 | 18.5/37/55 | customized |

| ZKBM500-3 | 500 | 5-8 | 37 | customized |

| ZKBM500-4 | 500 | 8-12 | 55 | customized |

| ZKBM650 | 650 | 10-15 | 37/45 | customized |

| ZKBM750 | 750 | 15-20 | 75/90/110 | customized |

| ZKBM850 | 850 | 20-25 | 90/110 | customized |

| ZKBM1000 | 1000 | 25-30 | 90/110/132 | customized |