Изделия для резки

- Категория: Roofing Felts >>>

- Поставщик: Hongzhida,Packaging,(shenzhen),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.81 $* | 0.4 $* |

| Aug-15-2025 | 0.12 $* | 0.27 $* |

| Jul-15-2025 | 0.79 $* | 0.84 $* |

| Jun-15-2025 | 0.79 $* | 0.89 $* |

| May-15-2025 | 0.79 $* | 0.68 $* |

| Apr-15-2025 | 0.62 $* | 0.14 $* |

| Mar-15-2025 | 0.75 $* | 0.59 $* |

| Feb-15-2025 | 0.58 $* | 0.26 $* |

| Jan-15-2025 | 0.64 $* | 0.26 $* |

Характеристики

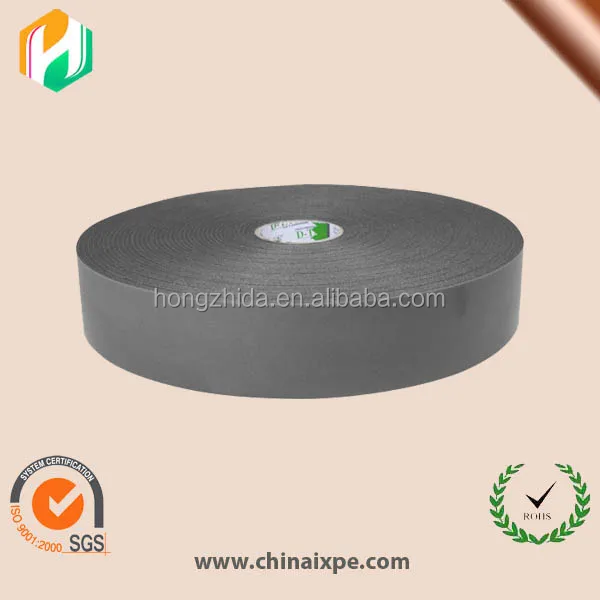

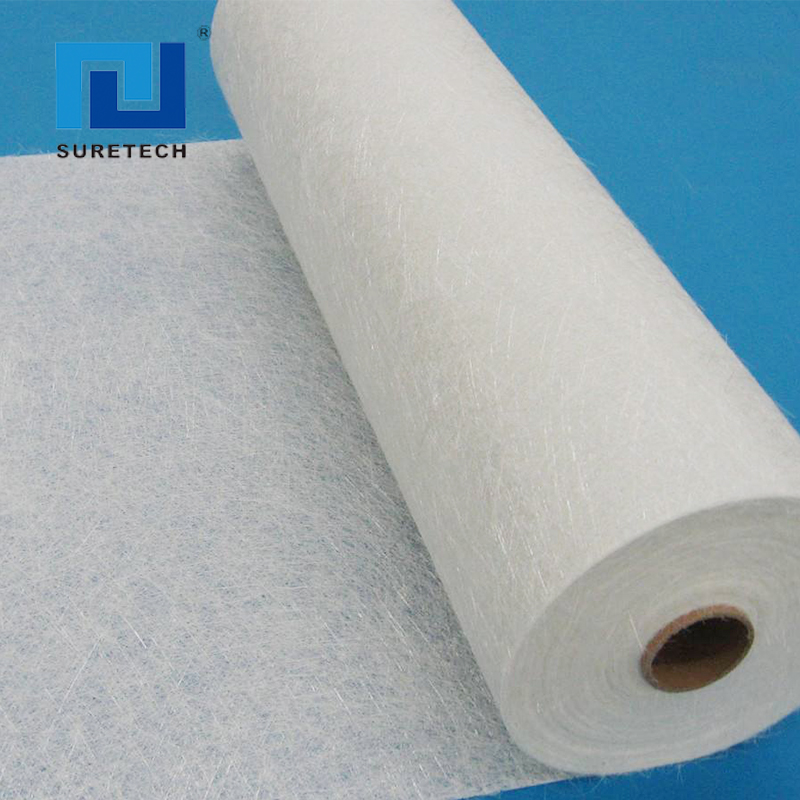

XPE foam cutting

XPE foam is closed cell foam made from Polyethylene and blended copolymers. It has a high level of chemical cross linking. The result is semi-rigid product with a fine uniform cell structure that is suitable for use in a wide variety of situations and applications.

Our featured foams are able to be supplied in sheets, blocks or profile cut to meet your demands.

Featured advantages

• Non-toxic and odor-free

• Oil & grease resistant

• Impact and vibration absorption

• Moisture proof and sound insulation

• Suitability for thermo-forming and thermo-molding

Data sheet

| Product name: | XPE FOAM |

| Materials: | Low density polyethylene |

| Density: | From 28kg/m3 and 200kg/m3 |

| Thickness: | From 3mm to 15mm |

| Width: | 1000mm, 1200mm, 1500mm |

| Length: | optional |

| Optional service: | Laminating, cutting and slitting |

| Supplied Form: | Rolls, sheets and sponges |

Technical specifications

| Property / Testing Standard | Unit | XPE-010 | XPE-015 | XPE-020 | XPE-025 | XPE-030 |

| Density / GBT6343 | kg/m3 | 100±10 | 65±5 | 50±5 | 40±5 | 33±3 |

| Tensile strength / GBT10808 | MPa | 1.3/0.9 | 0.8/0.6 | 0.65/0.5 | 0.5/0.35 | 0.35/0.25 |

| Tear strength / GBT6344 | N/cm | 45/60 | 33/41 | 22/28 | 20/26 | 15/19 |

| Thermal conductivity / GBT3399 | W/m.K | 0.052 | 0.050 | 0.048 | 0.047 | 0.046 |

| Water absorption / GBT8810 | mg/cm2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 |

| Service temperature | degree | From -80 to +120 | ||||

Factory overview

Product display

Studay case

Production flow chart

![]()

Why will you choose us?

• Outstanding technology and knowhow that answer customer production and quality requirements.

• Our advanced production facilities that enable us to meet changing market demands.

• And –above all – superior customer service.

• Our R&D department is constantly working to further improve HZD™’s products. We also work with customers around the world, both to develop innovative solutions for specialized requirements and to provide technical support.

![]()

![]()

Office Tel. | +86-0769-82928696 |

Skype: | steven.foam |

E-mail: | steven.foam at hotmail.com |

Website: | www.chinaixpe.com |

Address: | NO.6 Hongli Road, Dalang Town, Dongguan, Guangdong, China 523000 |