Автоматический диспенсер для органического силикона полиуретановый герметик эпоксидной

- Категория: Gluing Machines >>>

- Поставщик: Guangzhou,Zhengqi,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 777343.2 $* | 792890.12 $* |

| Jul-16-2025 | 630443.63 $* | 643052.63 $* |

| Jun-16-2025 | 765101.36 $* | 780403.81 $* |

| May-16-2025 | 758980.20 $* | 774160.66 $* |

| Apr-16-2025 | 605960.72 $* | 618079.29 $* |

| Mar-16-2025 | 746739.39 $* | 761674.86 $* |

| Feb-16-2025 | 740618.96 $* | 755430.62 $* |

| Jan-16-2025 | 734497.74 $* | 749187.60 $* |

Характеристики

3 axis automatic epoxy resin ab glue dispensing machine dispenser gule automatic

Choosing Meter Mix Dispense Equipment

In applications the dual cartridges are impractical due to large quantities used. Dispensing equipment can be used to assure the correct mix ratio, then the adhesive is dispensed through adynamic /static mix tip.

Piston Pump metering and mixing dispensing equipment is ideal for higher viscosity epoxy and medium production output.

Cylinder pump metering and mixing dispensing equipment is preferred for lower viscosity adhesives and are used in fully automated high production environments.

2-component dosing / dispensing

Nowadays a modern production without two-component materials is unimaginable.

I.Machine description and working principle

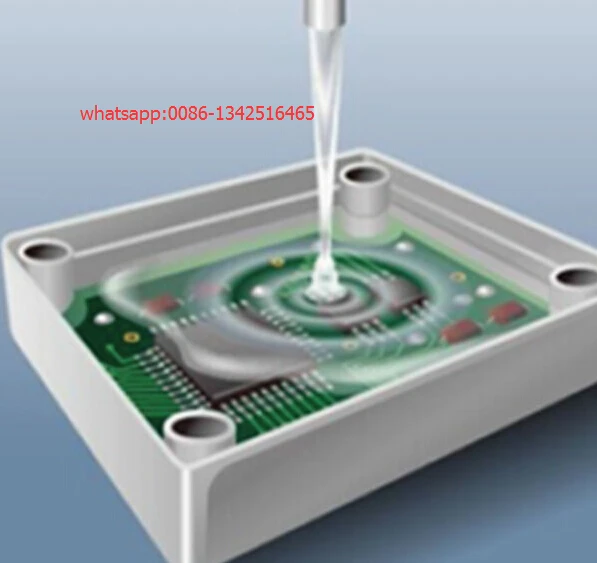

Automatic glue mixing machine is mainly used for a two-component glue( Epoxy/ Silicone/PU,etc adhesive), automatic metering and mixing the ratio of glue. The glue are stored in two barrels separately, according the glue weight ratio and volume demand automatic metering by two sets of precision pump, supply to a mixing device fully mixing, and then potting/dispensing the desired products.

II.Main Function:

1.Automatic metering and mixing

2.Manual Gluing

3.Auto alarm for lack of material or full material

4.Gluing ratio and quantity adjustable

5.Auto cleaning

6.Glue tank Vacuum Defoaming (Optional)

7.Glue barrels,metering pump,glue pipe can be heating (Optional)

Such as: Crystal or less additive glue --Silicone, epoxy, polyurethane(PU), etc.

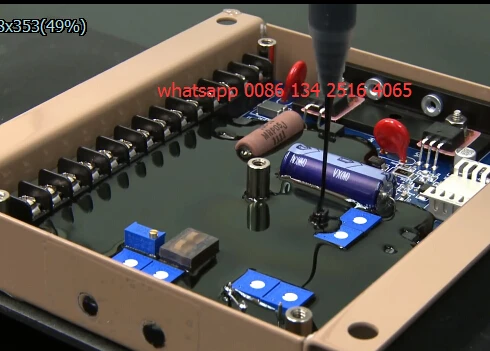

Applications:LED products ,Crafts,Electronic components

Such as:Wall washer light, LED bar, LED strip, Ads module, Sensor, Photovoltaic module, Photovoltaic inverter

| Floor type 2 components glue dispensing machine | |||||||

| Model | JYPJ-1000 | PGB-700 | PGB-1200 | PGB-1500 | PGB-3000 | PGB-200 | |

| Axis(mm) | X | 700 | 1200 | 1500 | 3000 | 480 | |

| Y | 700 | 1200 | 480 | 480 | 480 | ||

| Z | 100 | 100 | 100 | 100 | 100 | ||

| Dimension(mm) | L | 1050 | 1520 | 1765 | 1765 | 2015 | |

| W | 850 | 1150 | 1350 | 2050 | 2870 | ||

| H | 1500 | 1350 | 1350 | 1400 | 1350 | ||

| Weight(kg) | 255 | 350 | 400 | 450 | 600 | ||

| Package volum(CBM) | 1.2 | 3.5 | 4.5 | 5.5 | 9 | ||

| Rated power consumption | 380/220/110V 50/60Hz 900W (Optional) | ...2000W | |||||

| Moving Speed | 300mm/s | ||||||

| Moving Precise | ±0.05mm | ||||||

| Moving Path | Point, line, square, circle, arc,dome | ||||||

| Glue mixing ratio | 1:1~10:1 | ||||||

| Potting Speed | 5-66/5s(Adjustable) | ||||||

| Potting Precise | Amount±1%, Ratio:±1% | ||||||

| Air Pressure | 0.5-0.8MPa | ||||||

| Head Sealing pressure | MAX≤2.6Mpa | ||||||

| Glue water viscosity | <50000CPS(inquiry for above) | ||||||

| Operation Method | Auto, Manual | ||||||

| Program Method | Teaching Program | ||||||

| Electronic Control System | Smart control card+PLC+Touch Screen (Program setting, modify, save) |

||||||

| Glue Stop System | A, B Glue independent movement auto resorption system | ||||||

| Mixing Stirring System | High speed dynamic stirring mixing device(static option) | ||||||

| Glue ratio control | High precise metering pump | ||||||

| A,B glue supply system | A | Gear pump.screw pump.cylinder pump | Bucket stirring optional |

Heating optional |

10L,25L,40L Customizable |

Vacuumable | |

| B | Gear pump.screw pump.cylinder pump | ||||||

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com