China factory direct sale fiber block pallets for

- Категория: >>>

- Поставщик: Dongyue,Machinery,Group,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.83 $* | 0.48 $* |

| Aug-16-2025 | 0.45 $* | 0.1 $* |

| Jul-16-2025 | 0.90 $* | 0.91 $* |

| Jun-16-2025 | 0.31 $* | 0.25 $* |

| May-16-2025 | 0.65 $* | 0.32 $* |

| Apr-16-2025 | 0.53 $* | 0.86 $* |

| Mar-16-2025 | 0.51 $* | 0.48 $* |

| Feb-16-2025 | 0.44 $* | 0.35 $* |

| Jan-16-2025 | 0.61 $* | 0.88 $* |

Характеристики

Specification

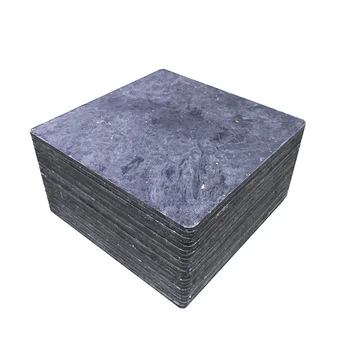

Pallet size | Size Customized |

Impact Strength | More than 30 KJ/m² |

Temperature tolerance | 60-90 degree |

Water Absorption | Less than 1% |

Theoretical life | More than 8 years |

Surface wearable | Shore 76D |

GMT Plate elastic modulus | 2.0-4.0GPa |

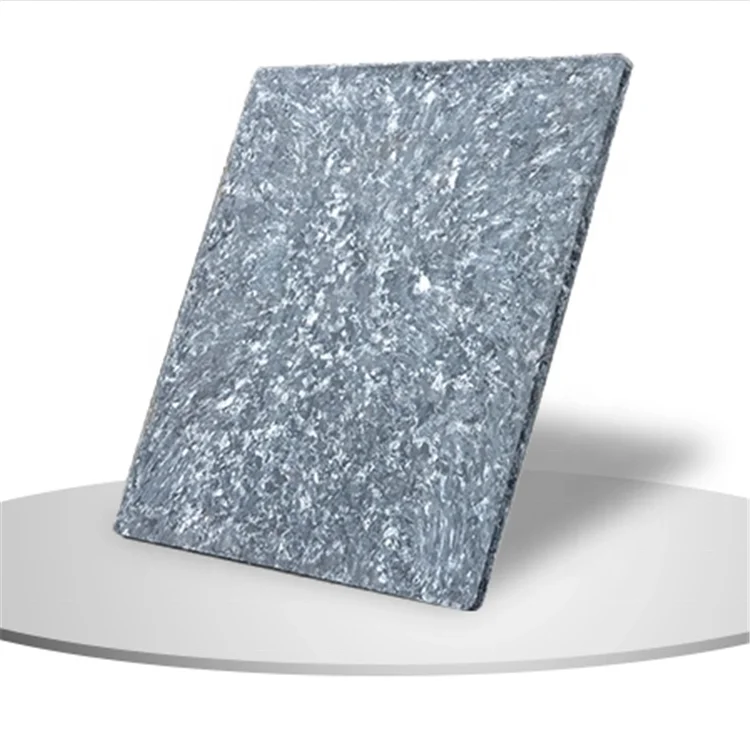

Detailed Images

Related Products

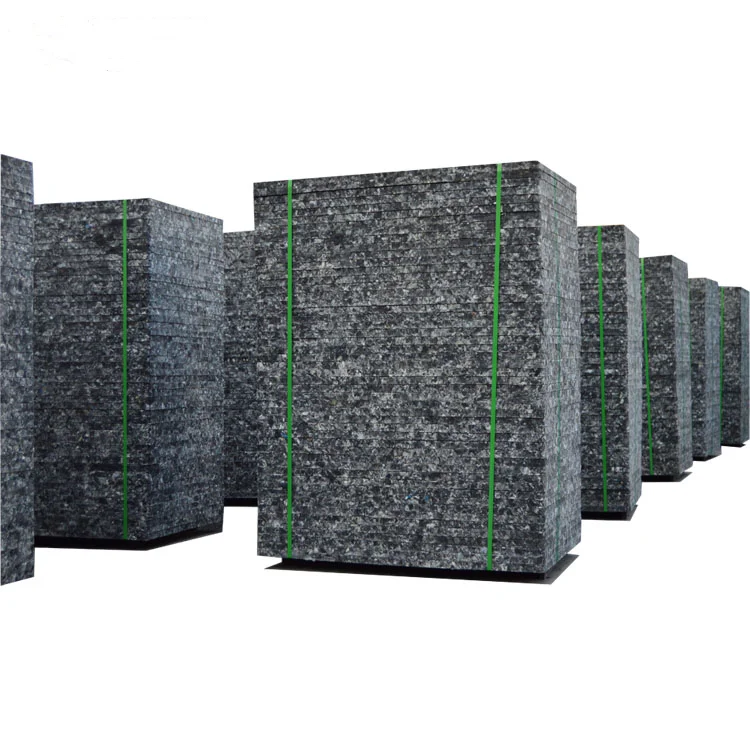

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

advantage

Advantages of GMT pallets

GMT(Glass Mat reinforced Thermoplastics), or glass fiber mat reinforced thermoplastic composite material, which is made of fiber

as reinforcing material and thermoplastic resin as base material made by method of heating and pressurizing. It becomes widely

used composite material in the world and is considered as one of the most prospective development new material in the 21st

century.

1.Light weight

Taking one pallet size 850*680 for example, with same thickness, our GMT pallet is lighter; for same weight, our GMT pallet is

thinner. GMT pallet is lightest with high strength.

2.High Impact Resistant

Impact strength of PVC plate is less than or equal to 15KJ/m2, GMT pallet is greater than or equal to 30KJ/m2, comparing the

impact strength under the same conditions.

Drop hammer experiment in the same height shows that: when GMT pallet slightly cracked, PVC plate has been breakdown by drop

hammer. ( Below is the laboratory drop tester: )

3.Good Rigidity

GMT plate elastic modulus 2.0-4.0GPa, PVC sheets elastic modulus 2.0-2.9GPa. The following diagram: GMT plate bending effect

compared with the PVC plate under the same stress conditions

4.Not Easily Deformed

5.Waterproof

Water absorption rate <1%

6.Wear-resisting

Surface hardness shore: 76D. 100 minutes vibration with materials and pressure. Brick machine screw off, pallet is not destructed,

surface wear is about 0.5mm.

7.Anti-high And Low Temperature

Being used at min 20 degrees, GMT pallet won't deform or crack.

GMT pallet is able to withstand high temperature of 60-90℃, won't easily deform, and suitable for steam curing, but PVC plate is

easy to deform at high temperature of 60 degree

8.Long Service Life

Theoretically, it can be used more than 8 years

Похожие товары

Сверхпрочный жесткий дешевый 1200 hdpe евро пластиковый поддон китай

US $10.00-$20.00

Никогда не боялся влаги, ПВХ поддон, пластиковый поддон для бетонного блока

US $600.00-$680.00

Европа промышленности пластиковые виргинские HDPE сетки поддон

US $25.32-$28.32

Пластиковый поддон для литья под давлением с тремя направляющими

US $28.43-$32.77