Настраиваемые высокоточные внутренние спиральные микро конические зубчатые шестерни для

- Категория: Spur Gears >>>

- Поставщик: Micro,MIM,Japan,Holdings,Inc.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.8 $* | 0.83 $* |

| Aug-17-2025 | 0.57 $* | 0.22 $* |

| Jul-17-2025 | 0.17 $* | 0.37 $* |

| Jun-17-2025 | 0.93 $* | 0.75 $* |

| May-17-2025 | 0.24 $* | 0.10 $* |

| Apr-17-2025 | 0.78 $* | 0.99 $* |

| Mar-17-2025 | 0.72 $* | 0.95 $* |

| Feb-17-2025 | 0.29 $* | 0.67 $* |

| Jan-17-2025 | 0.13 $* | 0.13 $* |

Характеристики

Integrated helical gear and spur gear

Product Name | Integrated helical gear and spur gear |

Brand Name | Micro MIM Japan Holdings Inc. |

Place of Origin | Japan |

This component is produced with combined functions of helical gear and spur gear.

It is usually regarded that such component should be built from several parts with different functions through assembly steps.

However, μ-MIM® technology enables you to skip the assembly, and it leads to a shorter production period and thus reduction of the production cost when you are considering a mass production of similar components.

They are not produced simply small, but also with a moderate number of teeth. The module of 0.3mm or less for mass production of such a small gear is not feasible by CNC machining, but our μ-MIM® technology has achieved to the module of 0.025mm.

Furthermore, we are proud of the accuracy of our production method including the mould design, especially in such a project. This gear has been moulded in a mould designed specially.

Normally the parting lines, as well as gate marks would be expected on the surface of components. However, there seemed to be no irregular unevenness caused during moulding processes, even by optical

microscope.

We are able to produce micro metal components with high accuracy with our feedstock made of the super-fine metal powder and our original binder developed from our accumulated knowledge from plastic injection moulding, as well as with the precise tool created by the reliable partners.

Even 0.01mm tolerance range is feasible thorough the collaboration with us when the dimensions of your components are less than 5mm.

As a leading OEM MIM company, we are waiting for your enquiries.

Recommend Products

Gear

Medical forceps

Other

Micro MIM Japan Holdings Inc. and its group companies cooperate as a team to cater for various needs of our customers from different parts of the world.

Manufacturing section: Taisei Kogyo Co., Ltd., TAISEI KOGYO(THAILAND) CO., LTD.

Taisei Kogyo Co., Ltd. was established in January 1972 as a plastic injection moulding manufacturer. Aside from improving our technology in the plastic injection moulding, we organised an R&D group in Kyoto Research Park about 25 years ago, to start researching on MIM technology. We utilise our knowledge and experience from the plastic injection moulding and developed original MIM material (binder system and feedstock), which makes it possible to manufacture small and complex shaped MIM components for serial production. Taisei Kogyo Co., Ltd. has obtained ISO13485 in May 2019. TAISEI KOGYO (THAILAND) CO., LTD. was established in August 2011 and started its operation in 2012. We maintain the same production standard as Japanese factory.

Похожие товары

Цементный смеситель Hino Crown Wheel и шестерни

US $5.79-$6.89

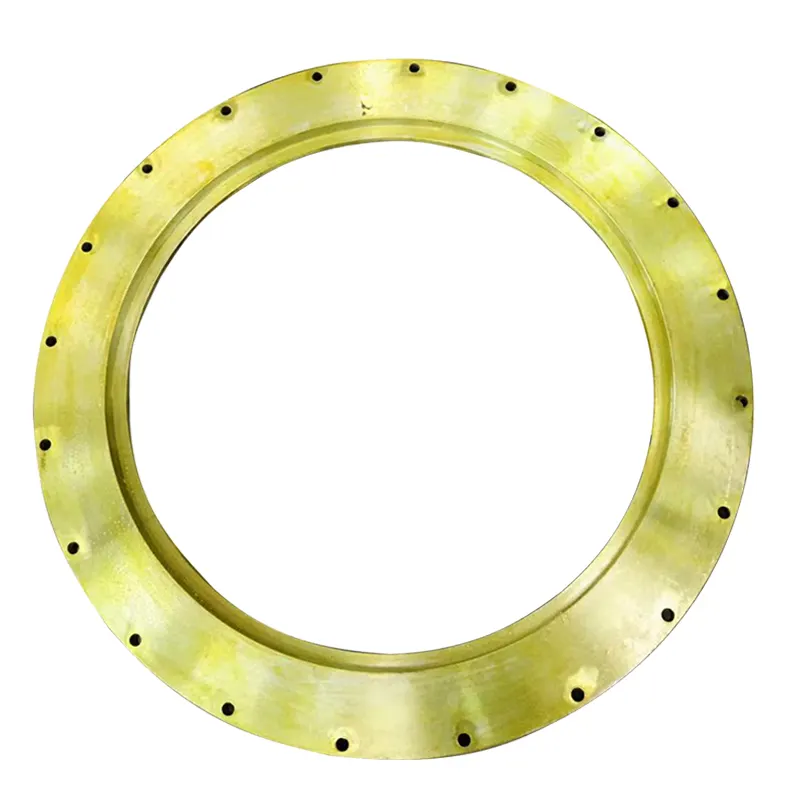

Спиральный угол 7, внутреннее спиральное кольцо

US $23.00-$87.00

OEM высококачественные медные шестерни из латуни

US $10.00-$99.00