Фрезерная вставка RCKT/ RDKT1204 из карбида вольфрама для резки

- Категория: Токарный инструмент >>>

- Поставщик: Zhuzhou,Jinggong,Cemented,Carbide,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.32 $* | 0.31 $* |

| Aug-17-2025 | 0.56 $* | 0.65 $* |

| Jul-17-2025 | 0.89 $* | 0.44 $* |

| Jun-17-2025 | 0.61 $* | 0.2 $* |

| May-17-2025 | 0.51 $* | 0.39 $* |

| Apr-17-2025 | 0.6 $* | 0.18 $* |

| Mar-17-2025 | 0.9 $* | 0.84 $* |

| Feb-17-2025 | 0.97 $* | 0.80 $* |

| Jan-17-2025 | 0.48 $* | 0.22 $* |

Характеристики

Tungsten Carbide Milling Insert RCKT/ RDKT1204-H2 For Steel Cutting

Tungsten Carbide Cutting Insert with different shapes and material for different cutting purpose and with high wear impact resistance which is a good substitution of ceramic insert, coating insert and alloy insert. It is suitable for hot process composite material for surface refurbishing and making capable to provide comprehensive coatings to enhance the wear resistance, thermal resistance, corrosion resistance and impact resistance of protect surface and special coatings of sealing, insulation and super-conduction.

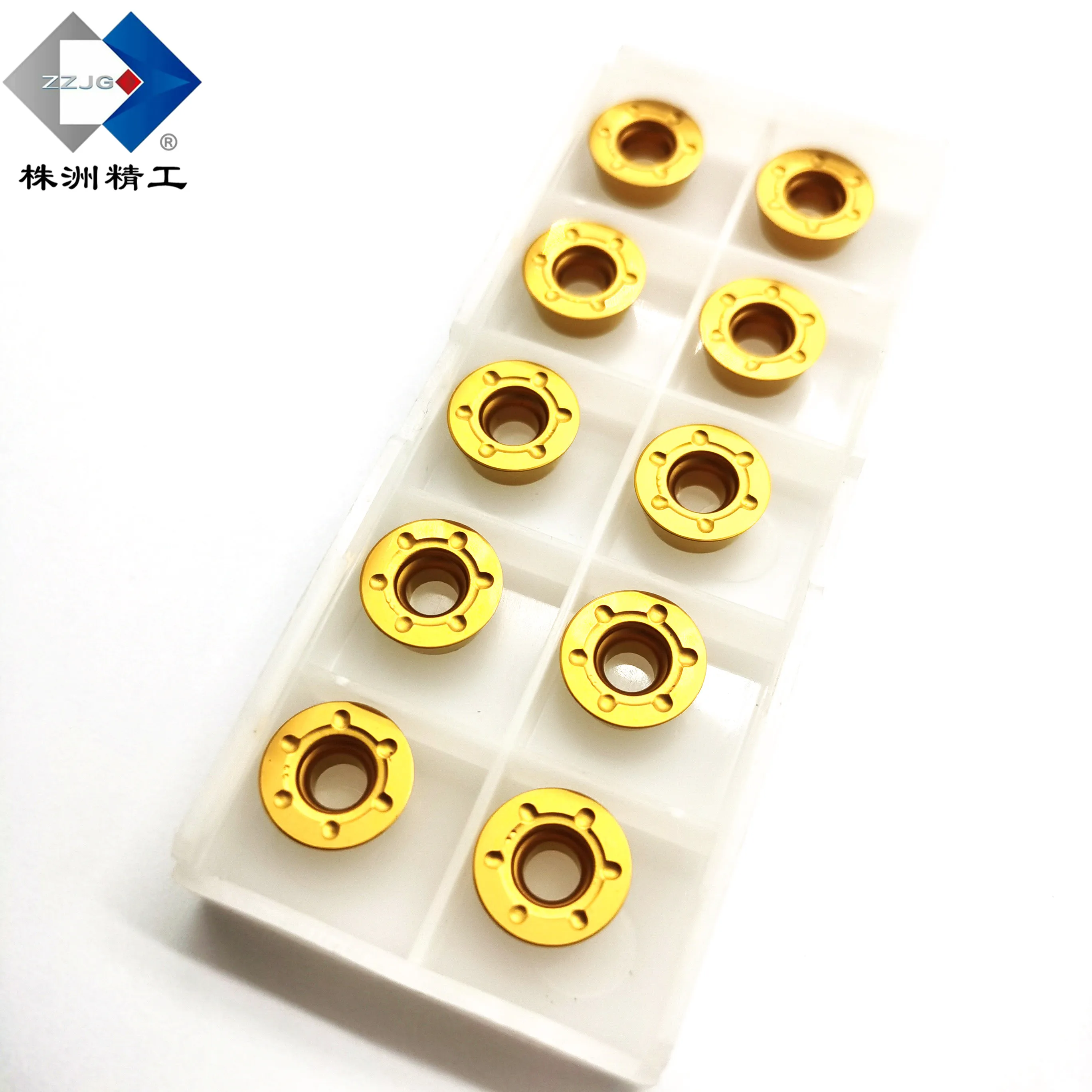

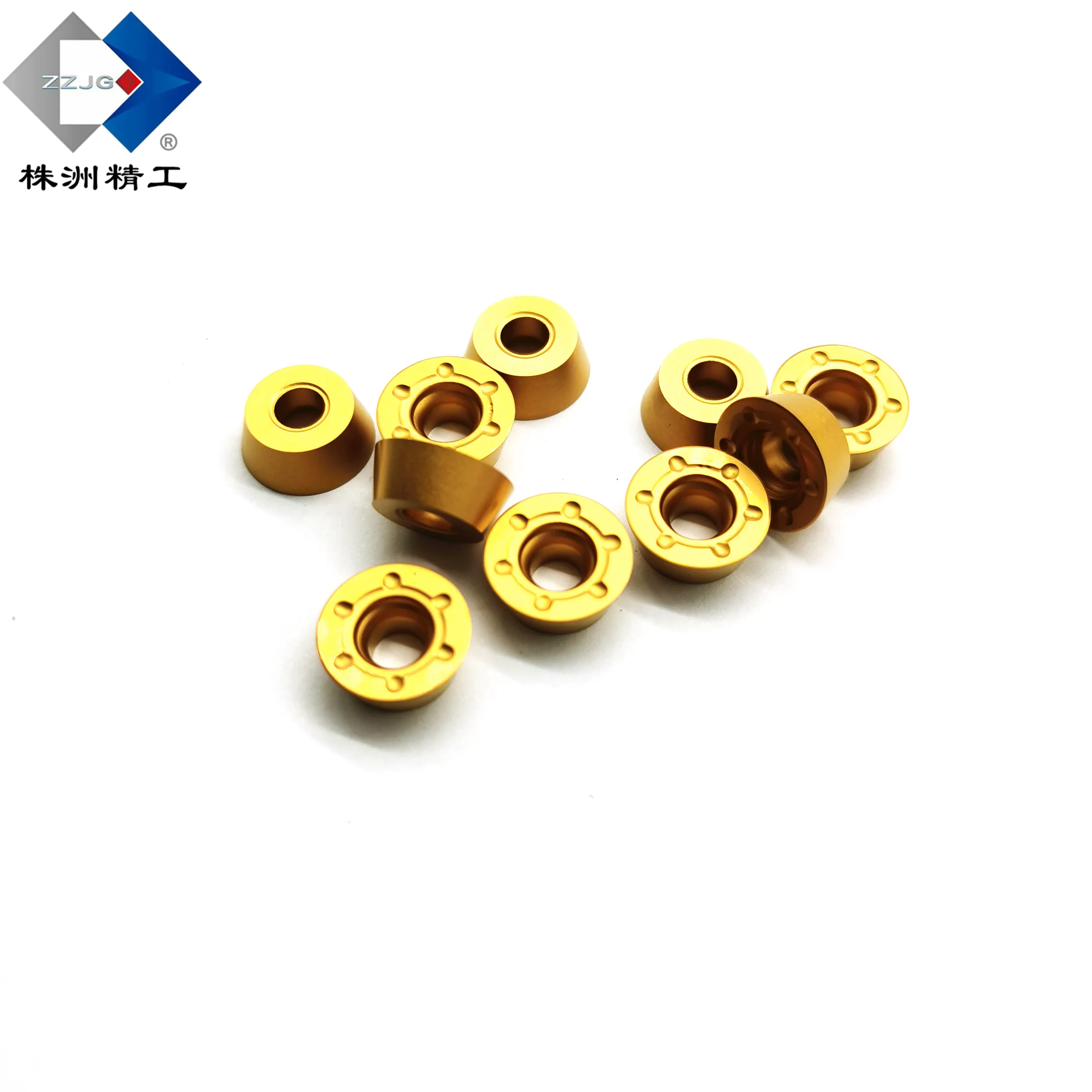

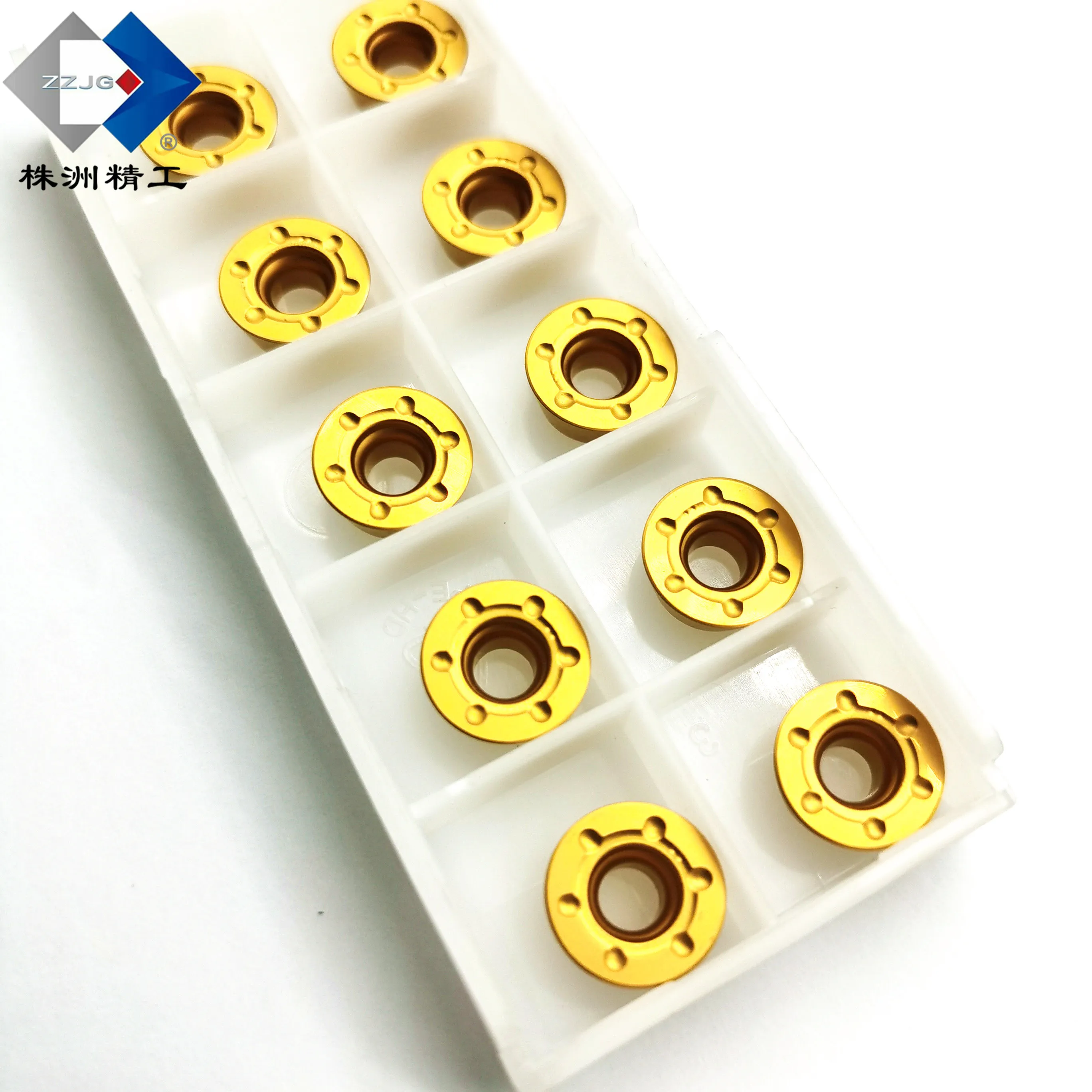

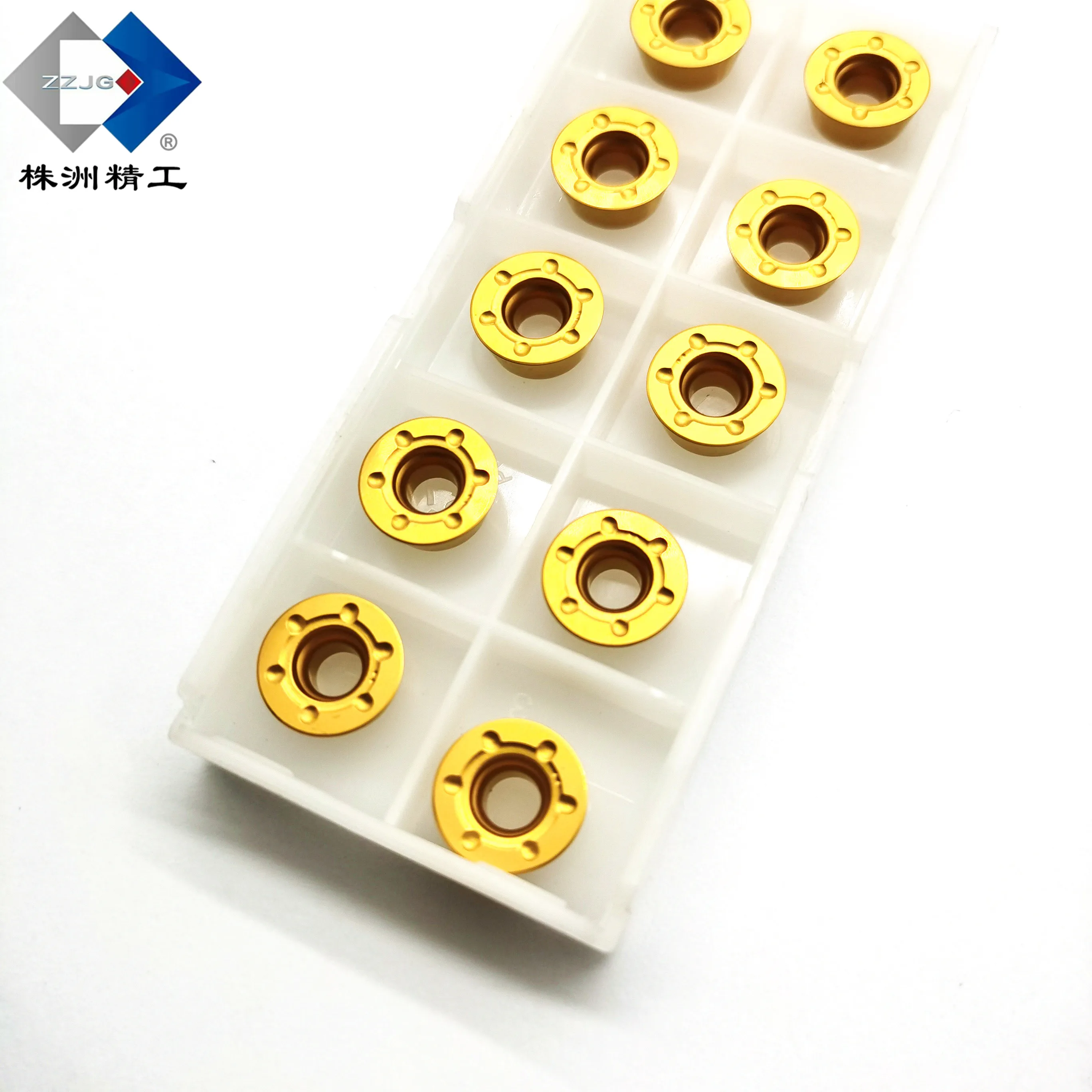

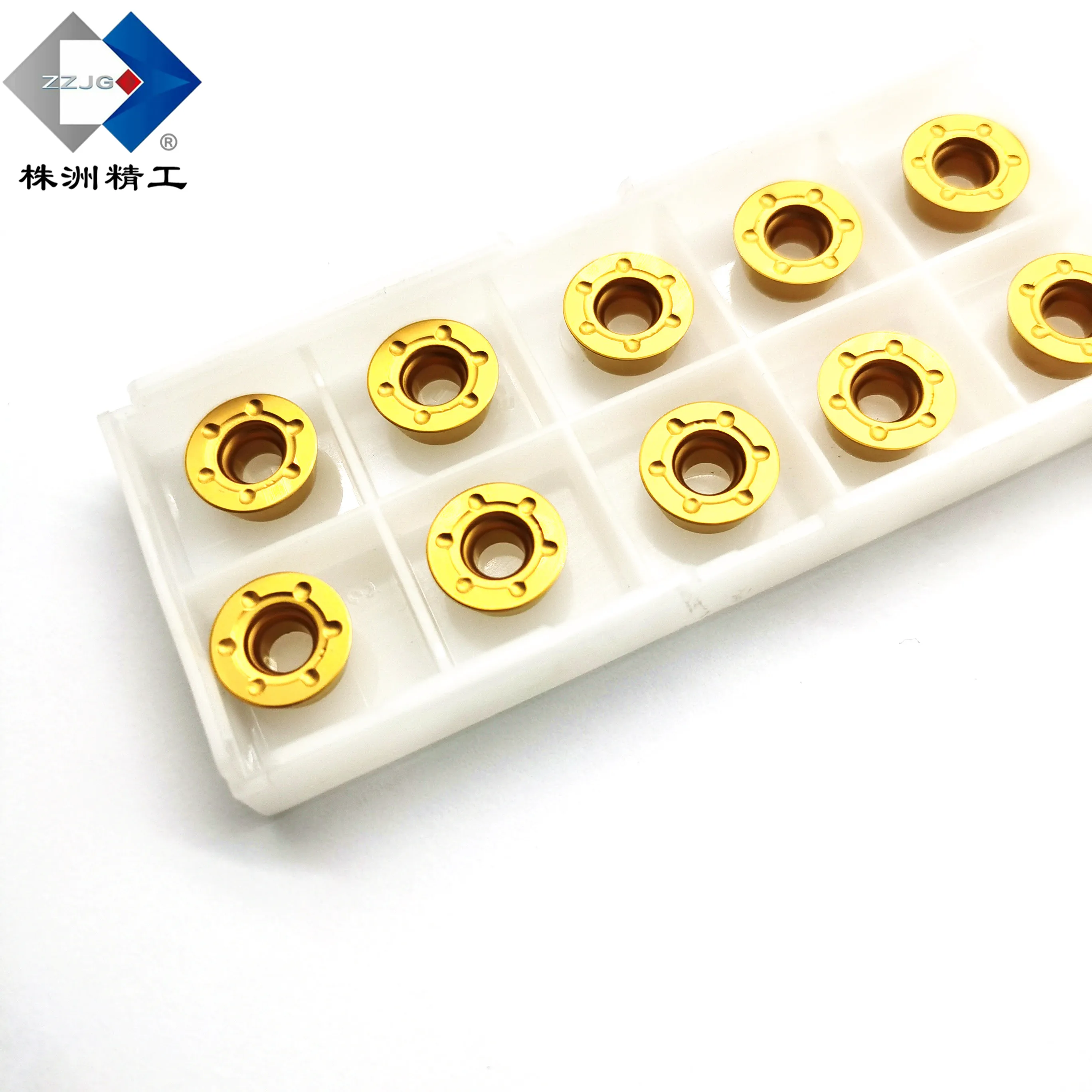

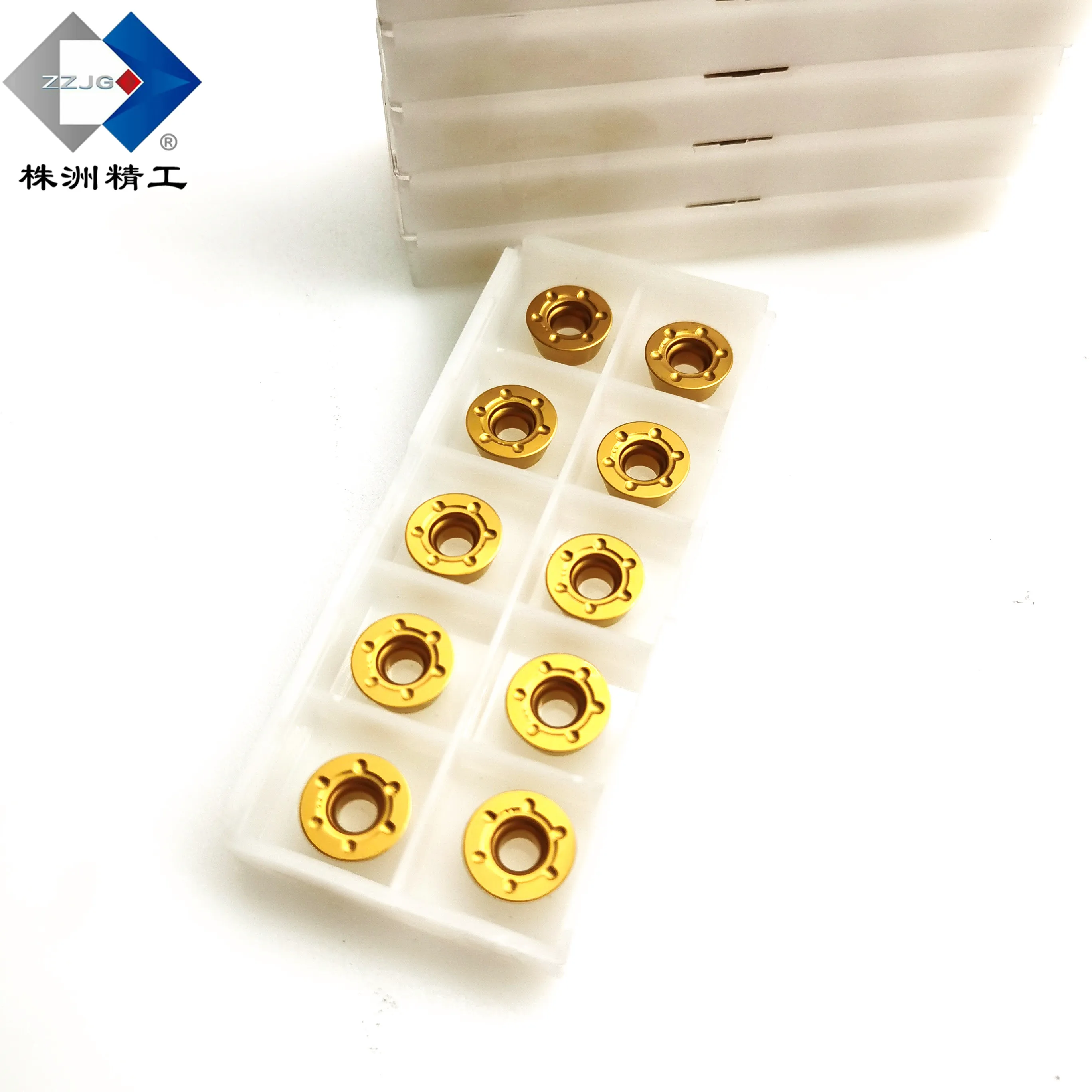

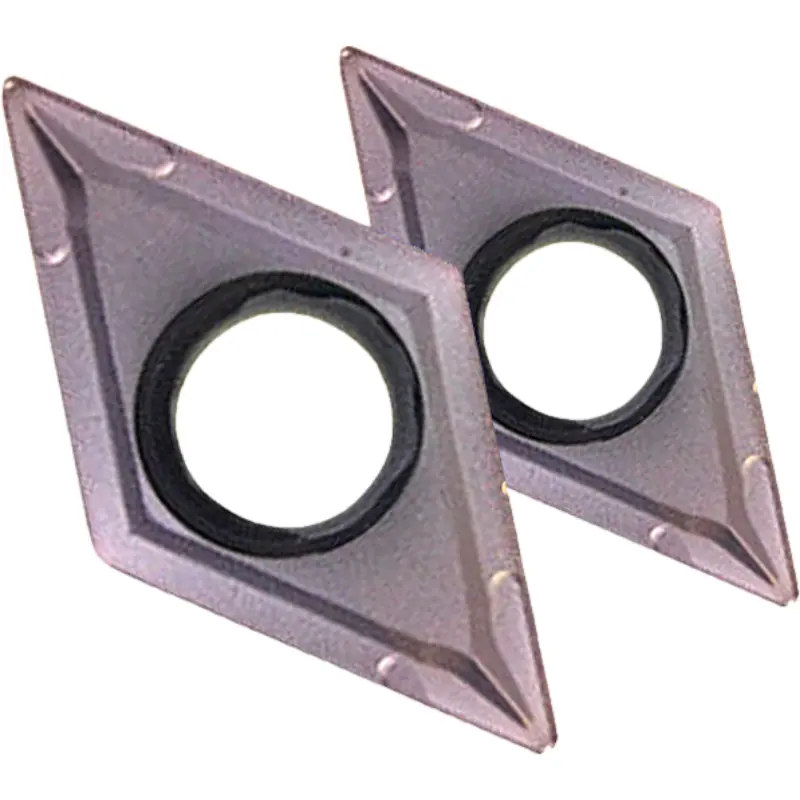

Pictures of cnc lathe milling carbide insert:

Specifications of cnc lathe milling carbide insert:

| Grade | Applications |

| JG1010 | General grade, Suitable for milling processing. |

| With excellent wear resistance,Processing high hardness material,with finish machining,semi-finish machining | |

| JG1015 | General grade, Suitable for milling processing. |

| With excellent wear resistance and toughness,Processing HRC20-HRC40 material with rough machining. | |

| JG1020 | General grade, Suitable for milling processing. |

| With excellent wear resistance and heat resistance,Processing under HRC30 material with rough machining. | |

| JG1120 | General grade, Suitable for milling processing. |

| With excellent wear resistance,with finish machining and semi-finish maching | |

| JG2010 | With excellent wear resistance and toughness body,plus CVD Coating. |

| Suitable for cutting stainless steel. with finish machining and semi-finish machining. | |

| JG2120 | With excellent toughness body and CVD Coating. |

| Suitable for cutting stainless steel. with finish machining and semi-finish machining. | |

| JG2030 | With excellent toughness and strength body,plus CVD Coating. |

| Suitable for cutting stainless steel with rough machining. | |

| JG3110 | With excellent wear resistanc body,plus CVD Coating. |

| Suitable for cutting iron cast. with finish machining and semi-finish machining. | |

| JG3120 | With excellent wear resistanc and toughness body,plus CVD Coating. |

| Suitable for cutting iron cast. with rough machining and semi-finish machining. | |

| JG4110 | With excellent toughness body,plus CVD Coating. |

| Suitable for turning soft steel,low carbon steel and low carbon alloy steel. | |

| JG4020 | With excellent wear resistance and toughness body,plus CVD Coating. |

| Suitable for cutting steel. with simi-finish machining and rough machining. | |

| JG4035 | With excellent toughness body,plus CVD Coating. |

| Suitable for cutting soft steel and low carbon steel. with rough machining. | |

| JT151C | Suitable for high quality turning the surface of steel, stainless steel and iron cast. |

| With excellent wear resistance,low friction and long working life. | |

| JT151 | Suitable for high quality turning the surface of steel, stainless steel and iron cast. |

| With excellent wear resistance and low friction. | |

| K10 | Suitable for general turning of iron cast,rare metal and non-ferrous material. |

| Such as aluminium alloy,copper alloy. with good wear resistance. |

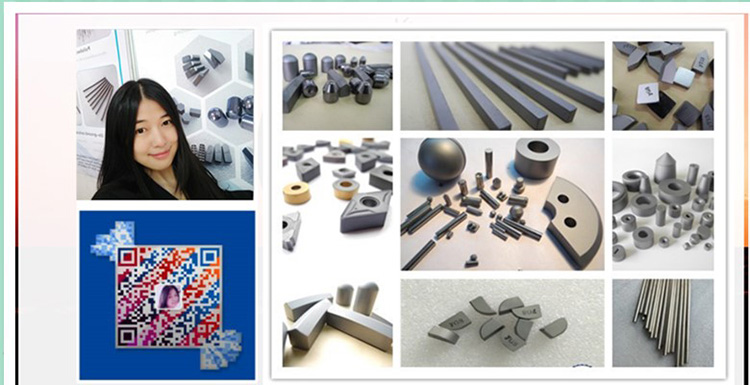

Various type for you to choose!

As you can see , we provide various plate of cemented carbide,of course ,we can also make products according to your drawings,we believe ,the co-operation with Zhuzhou Jinggong Company must be your optimal choice!

Our guarantee:

1. Here we can guarantee all our CNC inserts made by 100% raw material.

2. Professional manufacture for tungsten carbide items with 20 years experience.

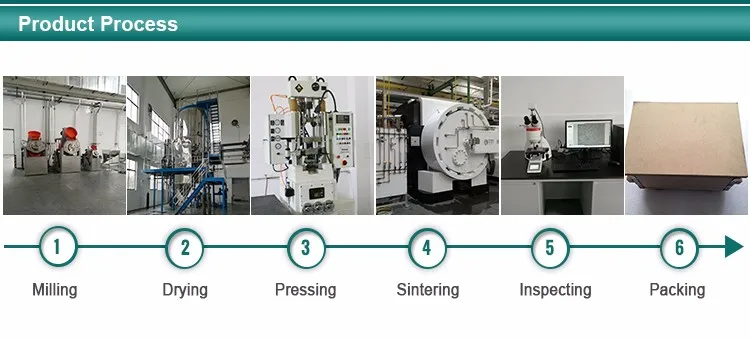

3. From power from to finished products all proceeded by machines without any directly hand touching.

4. Every pcs will be checked by microscope examination before sending.

5. Feedback within 24 hours.

6. ISO9001: 2008 certificate, ISO14001:2004.

7. Fully adopted in advance technology and equipments , expecially the Balzers coating machines and mechanial arm grinding machines .

8. Sintered in HIP Furnace.

Our guarantee:

1. 100% raw material.

2. Professional manufacture for tungsten carbide items with 20 years experience.

3. Size standard as per your requirements

4. Professional suggestion on products

5. Feedback within 24 hours

6. ISO9001: 2008 certificate, ISO14001:2004

7. Fully adopted in advance technology and equipment.

8. Sintered in HIP Furnace

9. Fully adopted in advance technology and equipment.

10. Quality Control System and strict inspection.

| >>>> Welcome to contact us for more details!welcome to contact us for more details |

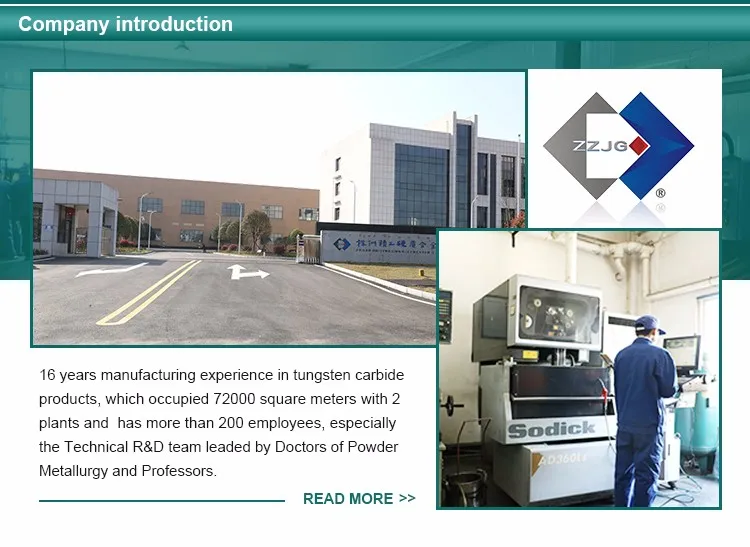

| Company information |

ZHUZHOU JINGGONG's Advantages in Carbide Industry:

1. We are a REAL factory located in Zhuzhou, with over 200 employees here for over 16 years.

2. We are Alibaba Assessed 6 years Gold Supplier.

3. Our output is over 80 tons per month.

4. Certificated by RoHS, ISO 9001:2008, ISO 14001:2004.

5. 100% QC inspection before shippment

6. Our products are produced by 100% Virgin material.

7. We can produce the non-standard items according to your samples or drawings.

Q1: What is the Warranty for the products?

A1: We use 100% virgin material to guarantee products high performance, We own high precision grading machine to control geometry dimensions and guarantee the lifetime of our products, which can satisfy every working condition.

If any quality problems on our side occurred in this period we will find a best way to reduce your loss, your satisfaction is our frist work!

Q2: Do you provide free samples?

A2: Yes, we welcome all client to get free samples for testing under the condition of freight paid by customer.

Q3: What is your minimum order requirement?

A3: Any trial order is warmly welcome.

Q4: What is the delivery time of your products?

A4: It depends on the inventory availability. If items needed are in stock, the delivery time would be within 8 work days, but if not the delivery time would be around 7-35 work days.

Q5: What kinds production do u supply?

A5: Tungsten carbide Rods/Bars, Tungsten Carbide Cold Punching Die/header, Tungsten Carbide Balls, Valve Seats and Buttons, Tungsten Carbide Rings, Tungsten Carbide CNC inserts, Tungsten Carbide Pins/Nuts/Bolts, Tungsten Carbide Strips and Plates, Tungsten carbide Saw tips.

Q6:Is non-standard products available?

Yes, we could design the drawing, develop high performance material, make the new mold according to your requirement.

More Questions? Welcome to Send Inquiry!

Your Senior Consultant : Enya.lee

Mob/WhatsApp:+86-15173277798 Tel: +86-731-22896701

Fax: +86-73122896778 Instagram: enyalee666

www.jgcarbide.com Skype: enyalee666

Tungsten Carbide Milling Insert RCKT/ RDKT1204-H2 For Steel Cutting