Agv робот логистика склада промышленный управляемый whicle Автоматические Управляемые транспортные средства подъемник транспортного ally Mobile Slam

- Категория: Другое грузоподъемное оборудование >>>

- Поставщик: EVER-POWER,INDUSTRY,PTE.,LTD.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 1735.39 $* | 1822.55 $* |

| Aug-17-2025 | 1720.9 $* | 1806.25 $* |

| Jul-17-2025 | 1443.19 $* | 1515.46 $* |

| Jun-17-2025 | 1691.78 $* | 1776.57 $* |

| May-17-2025 | 1473.60 $* | 1547.92 $* |

| Apr-17-2025 | 1662.19 $* | 1745.60 $* |

| Mar-17-2025 | 1648.25 $* | 1730.97 $* |

| Feb-17-2025 | 1633.69 $* | 1715.67 $* |

| Jan-17-2025 | 1618.79 $* | 1699.22 $* |

Характеристики

Product Description

Automated Guided Vehicles (AGVs) are commonly thought of as simple machines that perform simple tasks in lieu of personnel. And

while this is true in some regards, the last decade has seen AGVs become integrated into many industries outside of distribution

and manufacturing—such as retail, the military, and even healthcare

while this is true in some regards, the last decade has seen AGVs become integrated into many industries outside of distribution

and manufacturing—such as retail, the military, and even healthcare

Advantages of AGVs

1. Reduced Labor Costs

AGVs reduce labor costs in your operation in many ways: By replacing a human worker with an AGV, a company pays a single expense

for the equipment—the initial investment—versus ongoing costs that would come with a new hire such as healthcare coverage, payroll

taxes, salary increases, vacation time, etc.

AGVs reduce labor costs in your operation in many ways: By replacing a human worker with an AGV, a company pays a single expense

for the equipment—the initial investment—versus ongoing costs that would come with a new hire such as healthcare coverage, payroll

taxes, salary increases, vacation time, etc.

2. Increased Safety

AGVs are programmed with safety in mind, and as such are crammed full of cameras, lasers, and other sensors that allow them to

safely operate around personnel and structures. By contrast, equipment run by human operators, such as forklifts, do not have as

many built-in safety mechanisms and ultimately rely on human input, which can be compromised in any number of ways. Whereas a

human operator always has the potential to become distracted or fatigued, and therefore cause an accident, these are not concerns

when using AGVs.

Additionally, AGVs can operate in conditions that humans either aren’t able to operate in or in conditions that humans don’t

operate optimally in, such as in extreme heat or cold or around hazardous materials.

All of this increased safety leads to reduced cost and reduced operational downtime, which can ultimately increase the

profitability of many operations.

Increased Accuracy and Productivity

Simply put: Humans make mistakes. By replacing the human element with AGVs, you remove some of the potential for inaccurate

workflows, ultimately reducing waste and increasing output, allowing your operations to become more productive and accurate. And

whereas human personnel is limited in how long they can work, AGVs are capable of running 24/7.

In addition to the obvious improvements in accuracy and productivity, by integrating AGVs with a warehouse control system or a

warehouse management system, you can streamline processes such as inventory and materials ordering.

4. Modularity

As your operations expand, it is easy to add additional AGVs as necessary (this is sometimes called a “modular system element”).

This allows you to avoid an incredibly high initial investment because instead of purchasing 20 or 30 AGVs at once, you are able

to start with one or two and transition slowly, eventually expanding your fleet to a fully-automated or mostly-automated

operation.

AGVs are programmed with safety in mind, and as such are crammed full of cameras, lasers, and other sensors that allow them to

safely operate around personnel and structures. By contrast, equipment run by human operators, such as forklifts, do not have as

many built-in safety mechanisms and ultimately rely on human input, which can be compromised in any number of ways. Whereas a

human operator always has the potential to become distracted or fatigued, and therefore cause an accident, these are not concerns

when using AGVs.

Additionally, AGVs can operate in conditions that humans either aren’t able to operate in or in conditions that humans don’t

operate optimally in, such as in extreme heat or cold or around hazardous materials.

All of this increased safety leads to reduced cost and reduced operational downtime, which can ultimately increase the

profitability of many operations.

Increased Accuracy and Productivity

Simply put: Humans make mistakes. By replacing the human element with AGVs, you remove some of the potential for inaccurate

workflows, ultimately reducing waste and increasing output, allowing your operations to become more productive and accurate. And

whereas human personnel is limited in how long they can work, AGVs are capable of running 24/7.

In addition to the obvious improvements in accuracy and productivity, by integrating AGVs with a warehouse control system or a

warehouse management system, you can streamline processes such as inventory and materials ordering.

4. Modularity

As your operations expand, it is easy to add additional AGVs as necessary (this is sometimes called a “modular system element”).

This allows you to avoid an incredibly high initial investment because instead of purchasing 20 or 30 AGVs at once, you are able

to start with one or two and transition slowly, eventually expanding your fleet to a fully-automated or mostly-automated

operation.

Specification

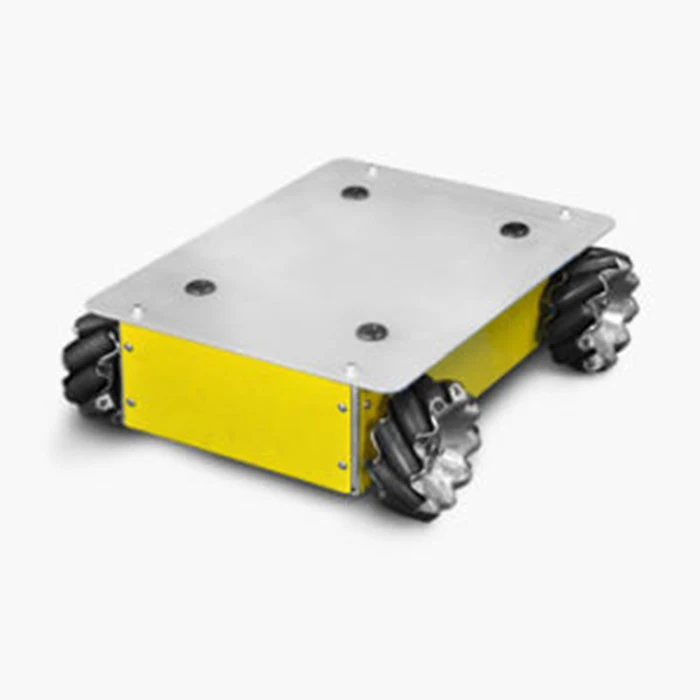

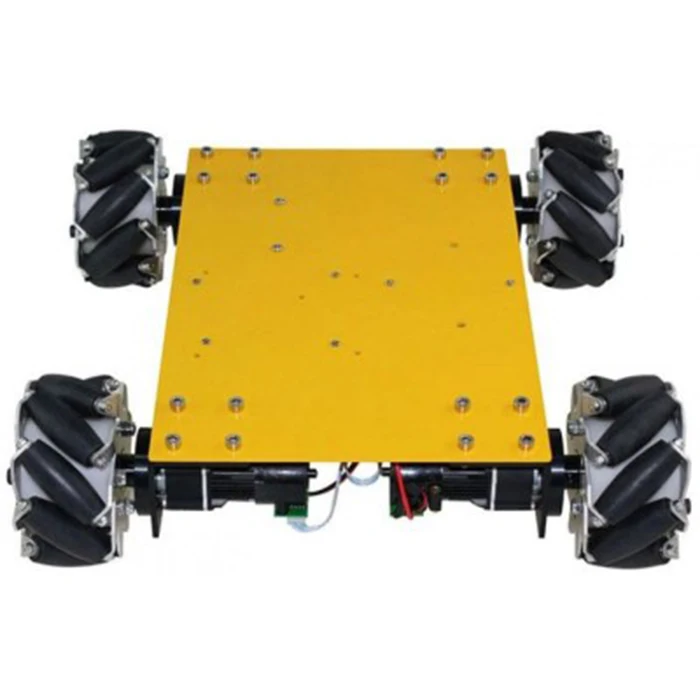

item | Mobile robot |

Application | material handling products and intelligent intralogistics & delivery solutions |

Features | ROBUST CHASSIS SUPERIOR REAL-TIME WIRELESS COMMUNICATION EASY USE, MAINTAINABILITY & EXTENDABILITY GREEN, HI-EFFICIENCY AND INTELLIGENT ENERGY SOLUTION |

Condition | New |

Dimension(L*W*H) | 930x650x290 |

Power(W) | 400W x 2pcs |

After-sales Service Provided | No overseas service provided |

Place of Origin | China |

Brand Name | EP |

Voltage | 24V IOOAh or 48V 48V 20Ah or40Ah |

Certification | |

Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Farms, Construction works |

After Warranty Service | Online support |

Packing & Delivery

PRODUCT INNOVATIONS & FEATURES I

NEXT-GENERATION NAVIGATION I

V-SLAM

98.7%

As a next-generation navigation, AGV+ vSLAM is based on 2D

safety laser scanner plus RGB-D camera vision system. This solution is sometimes

called natural or contour navigation.

O simplifies

payload integration

recovers from hijack

• urne

without initiation

O easily reconfigures facility

or machine layout

O easily deployed with no facility

modification

O localizes via a virtual map with

optional exact stop

function via 2D codes

O autonomously rectifies deviation and

senses people & unanticipated

obstructions with intelligent bypass

After the set-up process along with laser&camera to survey working area and generate precise reference maps,

this sophisticated localization and mapping algorithms are then used to guide vehicles during operation.

This solution remove the need for infrastructure change enabling easy expansion whilst delivering ultimate agility

for rapid route scheduling and rescheduling.

The local fixed structure environment around us tends not to be subject to major change on a day to day basis.

v-SLAM can maximize the efficient operation with such fixed environment and manage transient changes such as

inadvertent placement of movable objects e.g. boxes, chairs, pallets, people or other vehicles.

The OLS detects the luminescent line regardless of the physical features of the floor and background.

A separate teach-in process is not necessary, installing and maintaining lines will particularly be easy and

economical.

Thanks to the reliable luminescence detection, there's no need to worry about contamination.

Surface defects can be ignored over a length that can be adjusted by the customer.

The OLS reliably outputs the deviation from the center of the line and reads a-digit ID bar codes

perpendicular to the line. This makes it easy to transmit route or position information and drive commands.

Thanks to its wide reading field of 1 80 mm, the OLS can detect up to three lines. This enables flexible

arrangement of diverters or line junctions.

OPTICAL LINE

SENSOR (OLS)

Upto ±lmm

12

Company Profie

Ever-Power Industry Pte. Ltd., a young, dynamic, flexible company, specializes in making all kinds of mechanical transmission products and hydraulic transmission products, such as planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, PTO shafts, special reducer & related gear components and other related products, hydraulic cylinder, gear pumps and so on. Furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers' drawings.

We have exported our products to customers all over the world and earned a good reputation because top priority for Ever-Power Industry Pte. Ltd. is quality, not only product quality but also the quality of service offered to the customer. To this purpose, frequent inspections are carried out to guarantee that all production batches comply with the strictest requirements. Quality, reliability and inspections are distinguishing features of Ever power's working procedures aimed at offering the customer the best possible products on the market. The materials and products use pass all the tests laid down by the latest international standards, such as UNI EN ISO 9001.

With current 1500 workers and CNC turning machines and CNC work centers, we continue to make large investments in technology to support future product quality. Customers from both home and abroad are welcomed to contact us to negotiate business and cooperate with us.

For more details, please check out our products catalog and machine lists.

We have exported our products to customers all over the world and earned a good reputation because top priority for Ever-Power Industry Pte. Ltd. is quality, not only product quality but also the quality of service offered to the customer. To this purpose, frequent inspections are carried out to guarantee that all production batches comply with the strictest requirements. Quality, reliability and inspections are distinguishing features of Ever power's working procedures aimed at offering the customer the best possible products on the market. The materials and products use pass all the tests laid down by the latest international standards, such as UNI EN ISO 9001.

With current 1500 workers and CNC turning machines and CNC work centers, we continue to make large investments in technology to support future product quality. Customers from both home and abroad are welcomed to contact us to negotiate business and cooperate with us.

For more details, please check out our products catalog and machine lists.

FAQ

1. who are we?

We are based in Singapore, start from 2017,sell to North America(20.00%),South America(20.00%),Southeast Asia(20.00%),Eastern Asia(20.00%),Western Europe(20.00%). There are total about 501-1000 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Sprockets,Gears & Racks,Chains,Bushes & Hubs,Reducers & Gearboxs

4. why should you buy from us not from other suppliers?

Ever-Power Industry Pte. Ltd., a young, dynamic, flexible company, specializes in making all kinds of mechanical transmission products and hydraulic transmission products.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

We are based in Singapore, start from 2017,sell to North America(20.00%),South America(20.00%),Southeast Asia(20.00%),Eastern Asia(20.00%),Western Europe(20.00%). There are total about 501-1000 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Sprockets,Gears & Racks,Chains,Bushes & Hubs,Reducers & Gearboxs

4. why should you buy from us not from other suppliers?

Ever-Power Industry Pte. Ltd., a young, dynamic, flexible company, specializes in making all kinds of mechanical transmission products and hydraulic transmission products.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

Похожие товары

350 кг барабанный подъемник для пластиковых бочек

US $200.00-$500.00

Тягач-трактор с баком, 6 тонн

US $600.00-$1000