Компьютеризированная машина Rotogravure цвета печатная машина/биаксиально-ориентированной пластиковой ПВХ ПЭ из полиуретана с открытыми порами 2/4/6/8/10 для глубокой печати

- Категория: Машины для ротационной глубокой печати >>>

- Поставщик: Ruian,Huarui,Plastic,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.98 $* | 0.76 $* |

| Aug-20-2025 | 0.29 $* | 0.19 $* |

| Jul-20-2025 | 0.27 $* | 0.73 $* |

| Jun-20-2025 | 0.55 $* | 0.77 $* |

| May-20-2025 | 0.0 $* | 0.99 $* |

| Apr-20-2025 | 0.12 $* | 0.47 $* |

| Mar-20-2025 | 0.84 $* | 0.40 $* |

| Feb-20-2025 | 0.99 $* | 0.81 $* |

| Jan-20-2025 | 0.92 $* | 0.95 $* |

Характеристики

Model No. HRASY-600-1600

Plastic or Paper Computer Printer Automatic Machine

H.S. No. 8443170090

COMPUTER AUTOMATIC REGISTER GRAVURE MACHINE

(THREE MOTOR)

General information of computered rotogravure color printing machine

1.Purpose: computered rotogravure color printing machine is widely used in multi-chromaticity printing for all assortments of plastic(BOPP,PET,CPP,PE,NYLON,PVC),paper etc. rolling material ,its speed can be up to 150m/min

2. three motor synchronors closed control,two segment float tension,digital system control,easy to operate and control actully.

3.main transmission structure: frequency convertercontrol motor, transferred by couple-shaft, keep the steady pre.

4. Cylinder fixing: it adopts pneumatic clip, driving the core shaft to fix to the cylinder, horizontal adjust adpots manual type screw move

5,ink supply structure:adpots pneumatic diaphragm pump supply the ink cycle.

6. ink Blade system: blade adopts low-speed synchronous decelerating motor transmmit extra-heavry split type structure, whose angle and strength can be adjusted freely, and its pressure uses double-cylinder, which will prolong the lifetime of cylinder.

7. Embossing lifter system: Embossing system adopts double cylinder synchronous ascend and descend and use swing cylinder to ensure the stability of film tension

8. longitudinal automtic structure: longitudinal adjustment adopts electronic-photo examination and controlling feedback by micro-soft. Synchronic motor is adjusted by screw decelerating transmission to automatically register; its main characteristic is driving smoothly and register accurately..

9. Unwinding,rewinding tranction system: it adopts vector frequency motor and invertor closed loop control.two group float spindel structure.operate by man-machine interface

10, Unwinding,rewinding system: it adopts double shaft double working station rotary type , auto-cutting without stop and auto-receiving in rewinding, rewinding A/B shaft adpots moment motor control

11,Dry system: drying tunnel adopts centrifugal cycle blowing, with electronic heating in the outlet of the blowing in each segment, whose temperature is controlled by digital thermo-controlling.

12. cooling system: air-cooling fixing in the outlet of drying tunnel to keep film cooling but do not deforming and expanding, equipment separately exhanst air structure in the both side of machine.(option: water cooling device,the price is extra addtional)

Main technical parameter:

| Model | HRASY-600A | HRASY-800A | HRASY-1000A |

| Unwind width | 620mm | 820mm | 1020mm |

| Print speed | 50m/min | 50m/min | 50m/min |

| Max reel diameter | 600mm | 600mm | 600mm |

| Print cylinder diameter | 70-390mm | 70-390mm | 70-390mm |

| Registered precision | ±0.25mm | ±0.25mm | ±0.25mm |

| Heating power | 3.5kw | 4.5kw | 5.5kw |

| Weight | 1.5T | 1.8T | 2.0T |

| Overall size(m) | 2.8*1.2*1.7 | 2.8*1.4*1.7 | 2.8*1.6*1.7 |

Computerized gravure press parameter

| Model | HRASY-600M | HRASY-800M | HRASY-1000M |

| Print width | 600mm | 800mm | 1000mm |

| Print speed | 60-100m/min | 60-100m/min | 60-100m/min |

| Max reel diameter | 600mm | 600mm | 600mm |

| Print length(mm) | 200-1250 | 200-1250 | 200-1250 |

| Registered precision | <0.15mm | <0.15mm | <0.15mm |

| Tension range | 2-30kg | 2-30kg | 2-30kg |

| Main motor | 11kw | 15kw | 18.5kw |

| Traction motor | 2.2kw | 2.2kw | 2.2kw |

| Air source | 0.8Mpa | 0.8Mpa | 0.8Mpa |

| Fan power | 1.2kw | 1.2kw | 1.2kw |

| Cylinder diameter | 120-350mm | 120-350mm | 120-350mm |

| Overall size(m) | 2.8*2.0*2.5 | 2.8*2.2*2.5 | 2.8*2.4*2.5 |

(2) main technical data

1,Max. printing width 800mm

2,Max. speed 150 m/min

Plate cylinder diameter Φ120mm-Φ300mm

4,Register precision longitudinal≤±0.15mm (auto.)

Horizontal≤±0.2mm (manu.)

5,max Unwinding diameter Φ600mm

6,max rewinding diameter Φ600mm

(Variable because of different ink, film, familiarity of operator)

7,The structure of unwinding and rewinding: two-side rotary, double-shaft double-position

8,Ink supply type: ink pneumatic pump,cycle supply the ink

9,Doctor blade horizontal movement ±5mm

10,Max impression pressure: 500kg/full width

11,The tension control system: three-motor double float roll closed loop control

12,The scrop of tension 3-20kg/full film

13,Tension control precision ±0.2Kg

14, The cutting method: high speed without stop automatic cutting

15,clip type: airshaft Φ76mm (inner dia.) * Φ92mm(outer dia.)

16,Drying method: close electronic cycle hot air to dry

Option:hot air generator (by fuel)for heating resourse,price is extra addational

17, minmum Air pressure 0.6MPa

18,The flux of water cooling 4T/h

19,printing unit: 4 color

20,total power: 85kw

21,weight: 12T

22, Overall deminsion 8500*2450*3200mm

23,from right to left

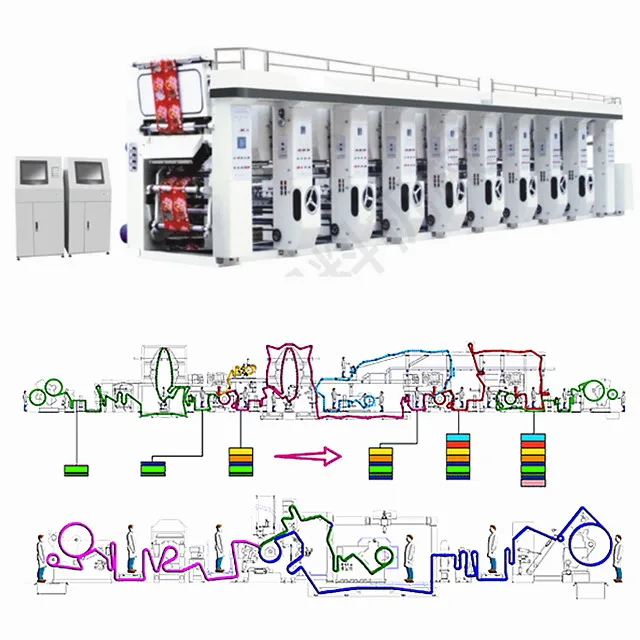

smple photos of computered rotogravure color printing machine :

computered rotogravure color printing machine features:

1. Independent tower type double arm duplex position slewing and wall rack combination.

2. Independent driving control system: Digital AC frequency control system.

3. Auto alarm change materials, new material auto driving at the same speed with main machine, automatic reel cutting and splicing, automatic adhesive tape position detection, alarm before reel changing,

4. High speed non-stop change material, automatic receiving and cutting in unwinding and rewinding without stopping, save time and improve efficiency.

5.AC control active unwinding, zero tension control, have steady output in both low or high speed. Pneumatic double-shaft blade, mobile range:±6mm. Achieve up-down registered, steady and fast high yield.

6. High-sensitivity tension closed loop control system, international brand float roll tension cylinder.

7. Install printing cylinder without shaft, tension controlled by dancer-roller, automatic rewinding tension weakening. Automatic vertical registration, pre-registration before printing, advanced ink-transferring roller system, centralized control by PLC and Human-machine interface.

8. Independent heating system in every color unit and water-cooling roller system.

9. Intelligent continuous constant temperature control, outside separate heat system.

10. Luxury and mannerly appearance design , wind insert closed oven.

11.Four float roll and seven-motor synchronous control in closed loop, international brand motor and vector frequency converter.

12..Driven by immersed-oil type pressurize gear box, which make the machine run more smooth.

13. Seven motors inverter control, shaftless pneumatic clamp for plate installation, two-position non-stop reel changing without speed changing, embossing rubber roller point-up and cylinder auto lock function.

14.Exact double lead screws and pre-register structure, electric lateral registration, high static picture and accuracy register system.

computered rotogravure color printing machine advantages:

New generation high speed computerized automatic registered gravure printing machine particular feature fully automatic, accurately registration, high output and high quality compared with our other competitors.

1.Unwinder and rewinder adopt turret type and automatic computerized cutting and splicing. 2.Seven vector motor and inverters tension control system with PLC controller.

3.Automatic color registration system with double lead screws and pre-register structure, electric lateral registration, high static picture and accuracy register system.

4.Shaftless printing cylinder loading device keep the printing cylinder flexible as well as accurate by which shaft-less air pressure chuck.

5.Aumatic ink circulating system controlled by a viscosity control instrument and circulating pump which feature the functions of monitor of viscosity, automatic injecting solvent and mixing the mixture.

6. Hermetically sealed hot air circulation oven, automatic constant temperature methods.

computered rotogravure color printing machine application:

New generation high speed computerized automatic registered gravure printing machine or rotogravure press is ideal for continuous multi-color printing on rolling materials in good printing performance such as cellophane, BOPP, PET, PVC, PE, aluminum foil complex film, paper and polymer film complex material, and paper, broadly applied for all types of super-quality printed matters with which excellent properties of thin film reel material printing and more continuous printing color, widely applied in all kinds of super grade printing process.

computered rotogravure color printing machine profile:

New generation high speed computerized automatic registered gravure printing machine or rotogravure press is suitable for all kinds of plastic film, paper and polymer complex film and paper etc. New generation high speed computerized automatic registered gravure printing machine or rotogravure press features reasonable design, fully automatic, accurately registration, high output and high quality international brand main electricity system etc. so it is the advanced high speed gravure printing machine.

1. Over 30 years experience in packing industrial.

2. Electric and mechanism component is strictly in accordance with CE standard.

3. Spare parts are processed by CNC lathe.

4. After-sale service: Prompt reply within 24 hours, professional & enthusiastic after-sales team.

package of computered rotogravure color printing machine :