Коврик из стекловолокна стекловолокно csm 450 для лодочного

- Категория: Стекловолокнистое полотно >>>

- Поставщик: Qingdao,Strong,Imp&Exp,Corp.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.45 $* | 0.1 $* |

| Aug-19-2025 | 0.72 $* | 0.18 $* |

| Jul-19-2025 | 0.91 $* | 0.1 $* |

| Jun-19-2025 | 0.49 $* | 0.39 $* |

| May-19-2025 | 0.6 $* | 0.0 $* |

| Apr-19-2025 | 0.70 $* | 0.9 $* |

| Mar-19-2025 | 0.61 $* | 0.79 $* |

| Feb-19-2025 | 0.88 $* | 0.19 $* |

| Jan-19-2025 | 0.87 $* | 0.7 $* |

Характеристики

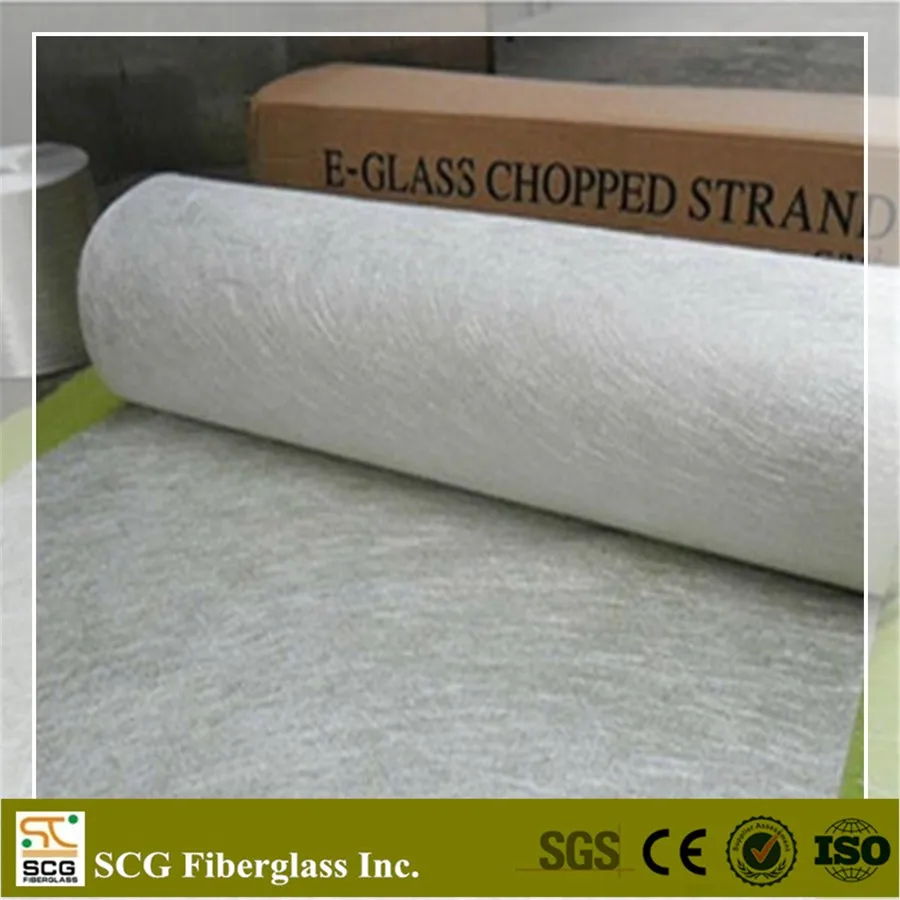

Fiberglass chopped strand mat

Fiberglass chopped strand mat is an non-woven E- OR C-glass fiberglass fabric manufactured by spreading continuous filament rovings of 50mm in length randomly and uniformly in combination with polyester binder in powder form or other binder in emulsion form.

Characteristic and application

Chopped strand mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost,.

It is suitable for the application by and hand lay-up FRP moudings, such as various sheets and penels, boat hulls, boat tubs, cooling towers, corrosion resistand, vehicles and so on.

Techincal data

Glass type: E-glass and C-glass chopped strand mat.

Bond type: Powder or Emulsion.

Density: 80g/m2-900g/m2.

Normal types: 180g/m2, 225g/m2, 300g/m2, 450g/m2, 600g/m2.

Bond content: 100g/m2(10%-15%), 300/450/600g/m2(4%-6%).

Roll width: 200mm-1300mm.

Normal types: 1040mm, 1250mm, 1270mm.

Roll weight: 28kgs-55kgs.

Normal types: 28kgs, 30kgs, 35kgs, 40kgs.

Property | Glass type | Weight (g/m2) | Moisture Content(%) | Combustible Content(%) | Breakage strength(N) |

Test method | GB/T 1549 | ISO3374:2000 | ISO3344: 1997 | ISO1887:1995 | ISO3342 |

EMC 80 | E/C-GLASS | 80 ± 16 | < 0.2 | 13.6±0.35 | ≥200 |

EMC 100 | E/C-GLASS | 100 ± 20 | < 0.2 | 9.5±0.35 | ≥170 |

EMC 150 | E/C-GLASS | 150 ±30 | < 0.2 | 8.0±0.35 | ≥40 |

EMC 225 | E/C-GLASS | 225 ± 45 | < 0.2 | 5.0±0.35 | ≥60 |

EMC 300 | E/C-GLASS | 300 ± 60 | < 0.2 | 4.0±0.35 | ≥90 |

EMC 450 | E/C-GLASS | 450 ± 90 | < 0.2 | 3.8±0.35 | ≥120 |

EMC 600 | E/C-GLASS | 600 ± 120 | < 0.2 | 3.6±0.35 | ≥150 |

EMC 900 | E/C-GLASS | 900 ± 180 | < 0.2 | 3.4±0.35 | ≥180 |

Note: Different specifications are available as per customers' requirements.

Roofing tissue

Roofing tissue is mainly used as substrate for water-proof roofing materials.

It can be used as the housing heat insulation layer.

This product is famous for theri high tension and corrosion proof, so they are the ideal baisc material for architectural stuff.

Product features.

>> Excellent fiber distribution.

>> Good tensile strength.

>> Good tear strength.

>> Good compatibility with asphait.

Product code | Area weight(g/m2) | Binder content(%) | Yarn distance(mm) | Tensile MD(N/5cm) | Tensile CMD(N/5cm) |

RM-30 | 30 | 16 | 10 | ≥ 180 | ≥ 65 |

RM-45 | 45 | 16 | 10 | ≥ 200 | ≥ 75 |

RM-50 | 50 | 16 | 10 | ≥ 220 | ≥ 85 |

RM-60 | 60 | 18 | 10 | ≥ 240 | ≥ 100 |

RM-90 | 90 | 20 | 10 | ≥ 280 | ≥ 200 |

Note: Different specifications are available as per customers' requirements.

B-grade chopped strand mat

B-grade chopped strand including cut-side, cut-pieces and small mat roll.

It is produced in our production process.

Description:

Characteristics

1, Thickness even, without hairiness, besmirch sundry etc.

2, Saturated with speed, products high strength, wet state strength loss less.

Application

Chopped strand mat is a kind of reinforcing that made from continuous fiberglass strand, which is chopped

Into a certain length, distributed in a random and non-directional position and bonded with binders.

It is suitable for hand lay-up, mold press, filament winding and mechanical forming etc., such GRP processes.

The main products include kinds of panels, boats, bath equipments, automobile parts and cooling towers etc.

Feature & Advantages

1 Quickly wet-out(resin), good molding property, easy to delete air bubbles.

2 Evenly distribution of fiber and binder.

3 Final products are with high mechanical strength, efficiently retain mechanical strength against boiled water.

Packing

Waste chopped strand mat be packaged in Nylon bags.

Package

Product is manufacturer in form of a roll warp on a paper tube then after packed in a plastic bag and placed within cardboard carton,

Rolls can be loaded in a container directly or on pallets.

Quantity:

20' GP Container: About 9-10tons.

40' HC Container: About 21- 22tons.

Depositde

Chopped strand mat should be stored in dry, cool, clean and rainproof area.

Recommended temperature range of storage is between 15-30 and relative humidity between 40-70%.

Fiberglass Yarn

ECG 37/75/150 ECE 225

ECD 450/900 and so on

Fiberglass Roving

Assumbled roving/Direct roving

For FRP, GRC and so on.

Fiberglass Insulation Fabric

116/2116/3732/3784/7628 and so on.

Fiberglass Chopped Strand Mat

Emulsion/Powder mat

225/300/450/600 gsm and so on.

Fiberglass Chopped Strand

Cut length according to client's requirements.

Fiberglass Mesh Fabric

For wall.

For grinding wheel.

We can guarantee that:

1. We are manufacturer and we can offer you a more composite price than trading company.

2. We can promise you a short lead time ( 10-15days ).

3. We are specializing in the fiberglass productions, can provide you many kinds of products.

4. We have 20 yeas experiences in export.

5. We have good after-sale service offered, please get back if you got questions.

6. We have well-trained & experienced staff are to answer all your inquiries in English of course, and also in Russia.

7. Every year we export containers all over the world. With our good quality products at competitive price . We have gain high reputation among our customers.