Полоса холоднокатаной стали 65 млн полоса горячекатаной с

- Категория: Alloy Steel >>>

- Поставщик: Guangdong,Lange,Steel,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 2.23 $* | 2.3 $* |

| Aug-19-2025 | 2.52 $* | 2.11 $* |

| Jul-19-2025 | 2.68 $* | 2.3 $* |

| Jun-19-2025 | 2.59 $* | 2.19 $* |

| May-19-2025 | 2.71 $* | 2.66 $* |

| Apr-19-2025 | 2.42 $* | 2.25 $* |

| Mar-19-2025 | 2.46 $* | 2.80 $* |

| Feb-19-2025 | 2.86 $* | 2.13 $* |

| Jan-19-2025 | 2.92 $* | 2.64 $* |

Характеристики

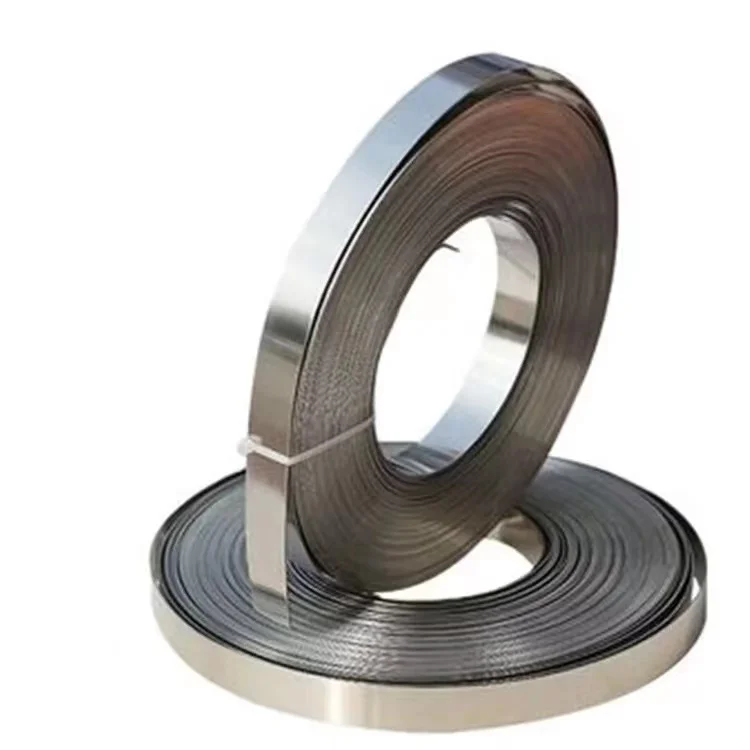

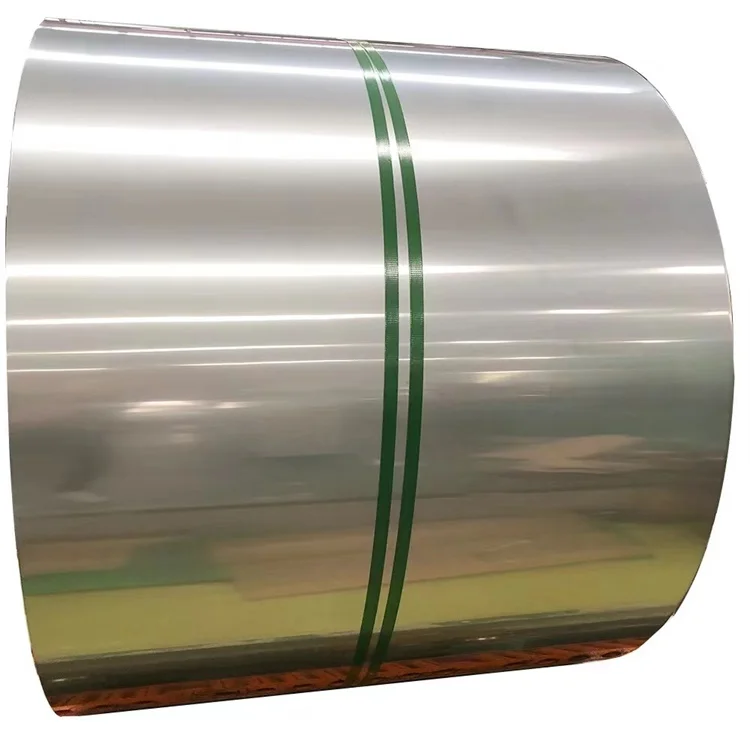

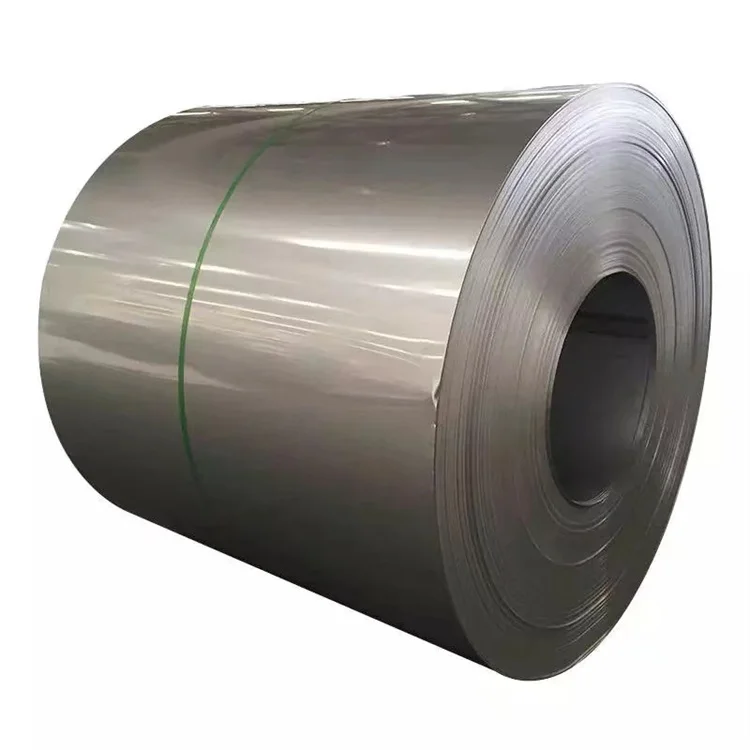

Product photos

Product Description

65Mn spring steel

After heat treatment and cold drawing hardening, the strength is higher, with a certain degree of toughness and plasticity. But hardenability is poor, mainly used for smaller size of the spring, such as pressure-regulating spring, force-measuring spring, the general machinery on the circle, square spiral spring or drawn into wire as a small mechanical spring.

chemical composition

C: 0.62-0.70 Si: 0.17-0.37 MN MN: 0.90.1.20 s: ≤0.035 p: ≤0.035 Cr: ≤0.25 Ni: ≤0.25 Cu: ≤0.25 Cu: ≤0.25

Mechanical properties,

tensile strength RM (MPa) : 500-637

yield strength RP0.2(MPa) : 430

elongation Δ10(%) : 14-21.5

section shrinkage ψ (%) : not less than 10

The strength, hardness, elasticity and hardenability of 65Mn steel plate are higher than that of 65Mn steel plate. It has the tendency of superheat sensitivity and tempering brittleness. Annealed state can be machinable, low cold deformation plasticity, poor weldability. Plate Springs with medium load, helical springs and spring washers up to 7-20mm in diameter. Spring ring. High wear-resistant parts, such as grinder spindle, spring chuck, Precision Machine Tool Screw, Cutter, spiral roller bearings on the ring, rail and so on.

chemical composition

C: 0.62-0.70 Si: 0.17-0.37 MN MN: 0.90.1.20 s: ≤0.035 p: ≤0.035 Cr: ≤0.25 Ni: ≤0.25 Cu: ≤0.25 Cu: ≤0.25

Mechanical properties,

tensile strength RM (MPa) : 500-637

yield strength RP0.2(MPa) : 430

elongation Δ10(%) : 14-21.5

section shrinkage ψ (%) : not less than 10

The strength, hardness, elasticity and hardenability of 65Mn steel plate are higher than that of 65Mn steel plate. It has the tendency of superheat sensitivity and tempering brittleness. Annealed state can be machinable, low cold deformation plasticity, poor weldability. Plate Springs with medium load, helical springs and spring washers up to 7-20mm in diameter. Spring ring. High wear-resistant parts, such as grinder spindle, spring chuck, Precision Machine Tool Screw, Cutter, spiral roller bearings on the ring, rail and so on.

Product display

About us

Packaging and delivery

FAQ

Frequently asked questions

Q: What kind of job is your company?

A: Our company is a professional manufacturer. We mainly produce nickel alloy products, nickel alloy seamless pipe, plate, rod, wire, belt and other metal products.

Q: What are your strengths?

A: First of all, we have an absolute advantage in the price. Secondly, in the product quality has also carried out strict control. In addition, we will strictly follow the customer's requirements, to provide customers with perfect customized services

Q: How long is your delivery time?

A: The product will be delivered as soon as possible on the basis of quality assurance.

Q: Which payment method can you choose?

A: Wire transfer, letter of credit, D / A, D / P, MoneyGram, Western Union and PayPal.

Q: How can your company maintain a long-term and stable business relationship with your customers?

A: 1. We provide consumers with considerate service and high-quality service. Guarantee the interests of consumers with preferential prices and careful packaging. 2. We have professional customer service personnel to solve all the problems before and after sales. 3. Professional researchers can meet all of your customized requirements.

A: Our company is a professional manufacturer. We mainly produce nickel alloy products, nickel alloy seamless pipe, plate, rod, wire, belt and other metal products.

Q: What are your strengths?

A: First of all, we have an absolute advantage in the price. Secondly, in the product quality has also carried out strict control. In addition, we will strictly follow the customer's requirements, to provide customers with perfect customized services

Q: How long is your delivery time?

A: The product will be delivered as soon as possible on the basis of quality assurance.

Q: Which payment method can you choose?

A: Wire transfer, letter of credit, D / A, D / P, MoneyGram, Western Union and PayPal.

Q: How can your company maintain a long-term and stable business relationship with your customers?

A: 1. We provide consumers with considerate service and high-quality service. Guarantee the interests of consumers with preferential prices and careful packaging. 2. We have professional customer service personnel to solve all the problems before and after sales. 3. Professional researchers can meet all of your customized requirements.

Похожие товары

H13 p20 p21 DC53 инструментальная Форма сталь

US $550.00-$600.00

HOT ROLLED SPRING STEEL FLAT BAR

US $590.00-$650.00

1095 Пружинные стальные полосы

US $900.00-$1500