Автоматический VFFS 100 г 250 500 1 кг упаковочная машина для сухих

- Категория: Packaging Machines >>>

- Поставщик: Foshan,Chuanglibao,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.21 $* | 0.70 $* |

| Aug-17-2025 | 0.25 $* | 0.79 $* |

| Jul-17-2025 | 0.12 $* | 0.66 $* |

| Jun-17-2025 | 0.19 $* | 0.28 $* |

| May-17-2025 | 0.42 $* | 0.14 $* |

| Apr-17-2025 | 0.48 $* | 0.50 $* |

| Mar-17-2025 | 0.3 $* | 0.14 $* |

| Feb-17-2025 | 0.45 $* | 0.55 $* |

| Jan-17-2025 | 0.62 $* | 0.25 $* |

Характеристики

Automatic VFFS 100g 250g 500g 1kg powder milk sachet packing machine pouch flour milk powder packing machine

The vertical form fill seal (VFFS) packaging machine is a fast and economical packaging solution that can effectively save floor space in the workshop and increase production efficiency. Because of this, this machine is widely used in production activities in various industries. If you are looking for an efficient and stable powder packaging machine, you are likely to be interested in this machine.

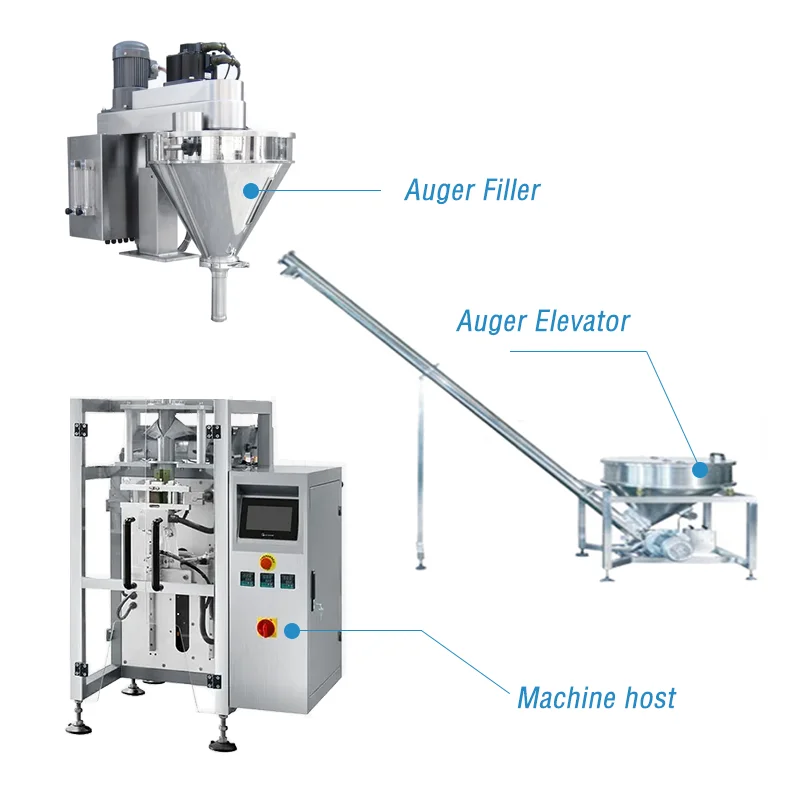

Auger elevator

Packing machine

Finished bags conveyor

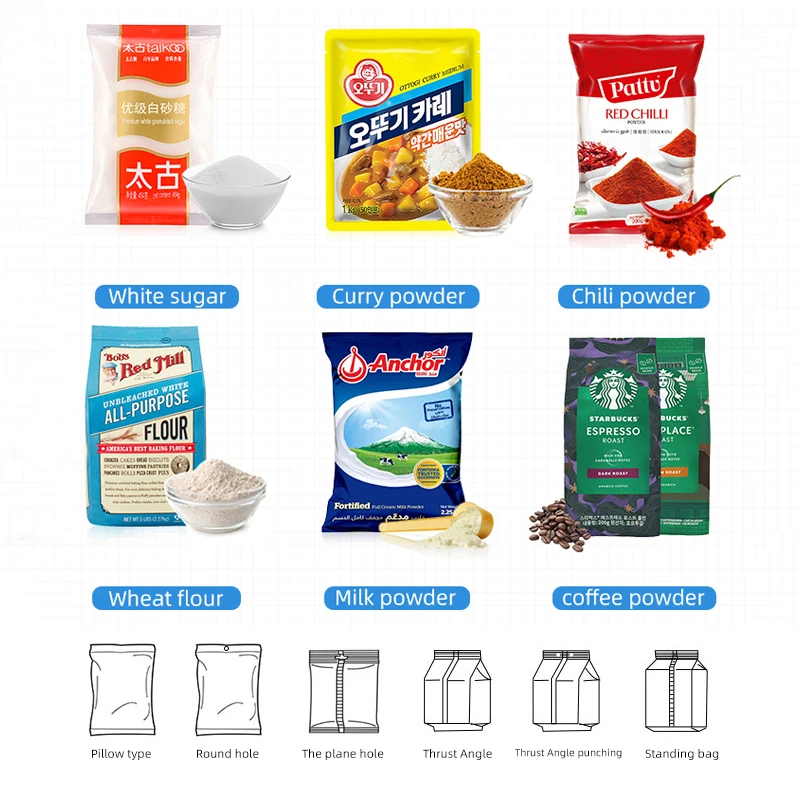

PACKING TYPE

This machine is suitable for many powder types of products:

Such as curry powder, milk powder, flour, starch, washing powder, spices, instant coffee, tea corn flour, beverage powder, bean powder, jelly powder, corn powder, cement, pepper powder, chili powder, fertilizer powder, Chinese herbal medicine powder, chemical powder, etc.

Such as curry powder, milk powder, flour, starch, washing powder, spices, instant coffee, tea corn flour, beverage powder, bean powder, jelly powder, corn powder, cement, pepper powder, chili powder, fertilizer powder, Chinese herbal medicine powder, chemical powder, etc.

PRODUCT DETAILS

The VFFS machine is equipped with an auger filler metering system which is ideal for powders and similar fine products. Each product has a special auger (worm auger) that precisely meters the correct dose directly into the forming tube of the packaging machine. The metering system can be easily disassembled for thorough cleaning.

Technical Specification | ||||||||

Model | CB-680PA | |||||||

Bag size | L(80-480)*W(50-330)mm | |||||||

Max width of roll film | 680mm | |||||||

Packing speed | 5-60bag/min | |||||||

Air pressure | ≥0.65Mpa | |||||||

Gas consumption | 0.4m³/min | |||||||

Powder voltage | 220/380V | |||||||

Power | 3.5KW | |||||||

Dimension | L1150*W1795*1650mm | |||||||

Net weight of machine | 720KG | |||||||

Machine Features:

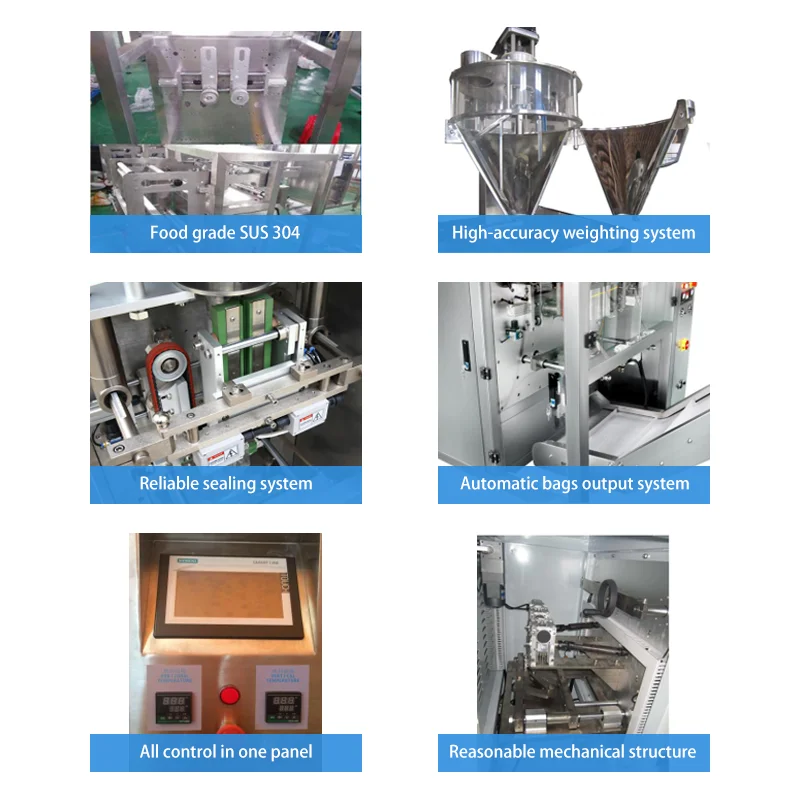

1. The equipment frame is made of food-grade 304 stainless steel for safety protection

Independent temperature control system is adopted, the temperature control is accurate, and the sealing is beautiful and smooth;

2. Servo motor film pulling, PLC control, touch screen control, automatic control capability of the whole machine, high reliability and intelligence, high speed and high efficiency;

3. It can be automatically adjusted through the touch screen to correct the deviation of the sealing and the incision, and the operation is simple;

4. The touch screen can store a variety of packaging process parameters for different products, which can be used at any time without adjustment when changing products;

5. The machine is equipped with a fault display system, which can help to troubleshoot in time and reduce the requirement for manual operation;

6. It can be made into pillow bags, pin bags, hanging hole bags, and even bags according to customer needs;

7. The whole machine adopts a closed mechanism to effectively prevent dust from entering the machine.

Independent temperature control system is adopted, the temperature control is accurate, and the sealing is beautiful and smooth;

2. Servo motor film pulling, PLC control, touch screen control, automatic control capability of the whole machine, high reliability and intelligence, high speed and high efficiency;

3. It can be automatically adjusted through the touch screen to correct the deviation of the sealing and the incision, and the operation is simple;

4. The touch screen can store a variety of packaging process parameters for different products, which can be used at any time without adjustment when changing products;

5. The machine is equipped with a fault display system, which can help to troubleshoot in time and reduce the requirement for manual operation;

6. It can be made into pillow bags, pin bags, hanging hole bags, and even bags according to customer needs;

7. The whole machine adopts a closed mechanism to effectively prevent dust from entering the machine.

Food grade SUS 304

High-accuracy weighting system

Reliable sealing system

Automatic bags output system

All control in one panel

Reasonable mechanical structure

Machine Options:

The machine must be connected to an air source to operate normally, so you need to purchase an air compressor. In addition, if your products need to be flushed with nitrogen to keep fresh, you also need to purchase a set of nitrogen-generating equipment. If necessary, we can also equip you with labeling machines, date printers and other devices to meet your production needs.

COMPANY INFORMATION

PRODUCTION PROCESS

HONORS & CERTIFICATES

EXHIBITION & CUSTOMER PHOTOS

PACKAGING & SHIPPING

FAQ

Q1: Are you a factory?

Q2: What info you need before confirming the machine?

A1: Yes, we established in 1998 as a manufacturing supplier with 25 years experience. We can provide you with professional product packaging solutions.

Q2: What info you need before confirming the machine?

A2: Your product picture, your product size(length,width,height,weight etc.),packing type(Back seal / quad seal / 3-side seal / 4-side seal etc),your product samples(for testing).

Q3: What is the material of contact food/material parts?

A3: The contact food/material parts are made of 304# stainless steel. The machine body can be 304# stainless steel or carbon steel.

Q4: Can this machine make different bag sizes?

A4: One former can make one bag width, and the bag length can be adjustable within a range. It should be ordered an extra former if you want to make the other bag width.

Q5: Does your company accept OEM?

A5: Yes, we have a professional design and technical team to accept customization.

Q6: When you can deliver the machine after the order is placed?

A6: We usually can arrange shipment after 30-40 working days, but it depends on the quantity of the products.

Q7: How about your warranty?

A7: We provide 13 months warranty, starts from the issue date of bill of lading.

Q8: What can you provide after service?

A8: We can provide machine testing video and pictures before delivery, English manual, some free spare parts, installation in clients' factory and technical training.

Q3: What is the material of contact food/material parts?

A3: The contact food/material parts are made of 304# stainless steel. The machine body can be 304# stainless steel or carbon steel.

Q4: Can this machine make different bag sizes?

A4: One former can make one bag width, and the bag length can be adjustable within a range. It should be ordered an extra former if you want to make the other bag width.

Q5: Does your company accept OEM?

A5: Yes, we have a professional design and technical team to accept customization.

Q6: When you can deliver the machine after the order is placed?

A6: We usually can arrange shipment after 30-40 working days, but it depends on the quantity of the products.

Q7: How about your warranty?

A7: We provide 13 months warranty, starts from the issue date of bill of lading.

Q8: What can you provide after service?

A8: We can provide machine testing video and pictures before delivery, English manual, some free spare parts, installation in clients' factory and technical training.