Китай вертикальная автоматическая двухслойная стеклянная машина с двойным остеклением изоляционная линия по

- Категория: Glass Production Machinery >>>

- Поставщик: Jinan,Ybke,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 17612.33 $* | 18493.23 $* |

| Aug-19-2025 | 17464.26 $* | 18337.31 $* |

| Jul-19-2025 | 14652.81 $* | 15385.72 $* |

| Jun-19-2025 | 17168.21 $* | 18026.94 $* |

| May-19-2025 | 14948.66 $* | 15695.36 $* |

| Apr-19-2025 | 16872.35 $* | 17716.72 $* |

| Mar-19-2025 | 16724.59 $* | 17560.75 $* |

| Feb-19-2025 | 16576.49 $* | 17405.95 $* |

| Jan-19-2025 | 16428.23 $* | 17249.98 $* |

Характеристики

Product Description

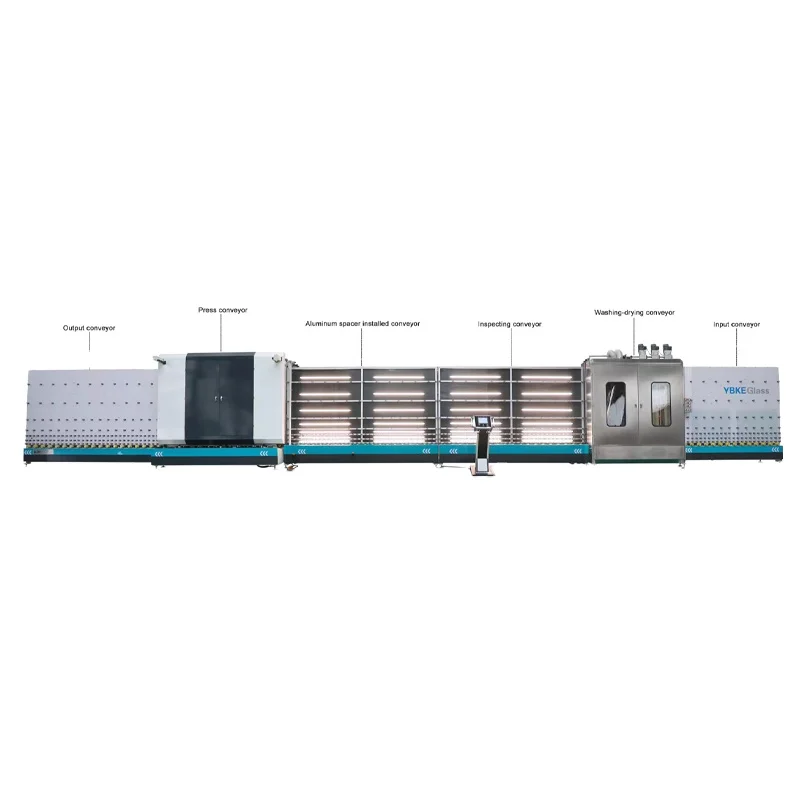

China Vertical Automatic Double Glazed Two-layer Glass Machine Insulating Low E Glass Production Line

The vertical fully automatic hollow glass plate pressing production line is a special equipment for processing grooved aluminum type hollow glass. It absorbs the advantages of equipment in the same industry at home and abroad, and integrates the requirements of users, and is independently developed and designed. The line has the advantages of energy saving, reliable performance and easy operation.

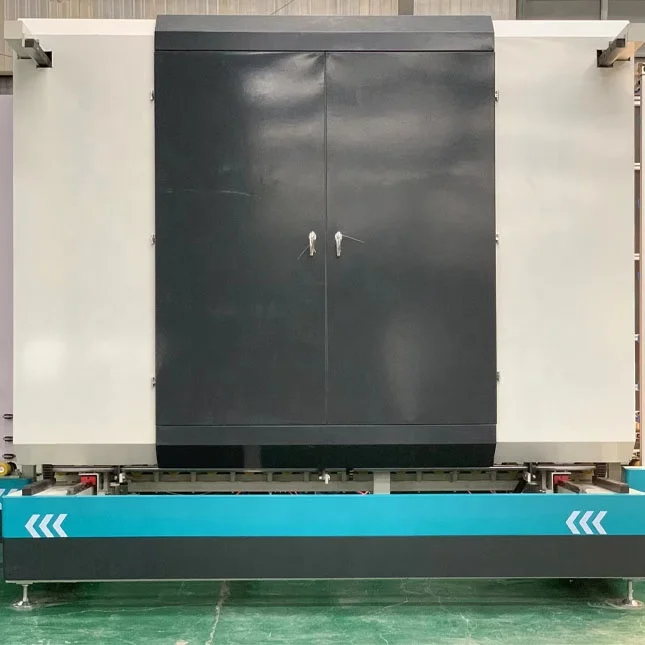

The production line is divided into seven parts: glass feeding section, glass cleaning and drying section, discharge inspection section, waiting section, aluminum frame placement section, automatic plate pressing section and turning section. The production line has glass positioning mechanism, aluminum frame positioning mechanism, Automatic lamination lifting mechanism, pressure plate micro-motion sensing mechanism.

The production line is divided into seven parts: glass feeding section, glass cleaning and drying section, discharge inspection section, waiting section, aluminum frame placement section, automatic plate pressing section and turning section. The production line has glass positioning mechanism, aluminum frame positioning mechanism, Automatic lamination lifting mechanism, pressure plate micro-motion sensing mechanism.

The selection of Taiwan Delta PLC, frequency converter, and touch screen will bring you intelligent operating procedures and perfect quality assurance.

PRODUCT SPECIFICATIONS

No | Item | Data |

1 | Power voltage | 380v 50hz |

2 | power rate | 20kw |

3 | insulating glass thickness | 50mm |

4 | washing glass thickness | 2-15mm |

5 | size of line | 15600X2350X3000mm |

6 | max. in washing section | 12m/min |

7 | max. glass size | 1800X2500/2800mm |

8 | min. glass size | 300X400mm |

Our Company

Jinan Enbeck Machinery Co., Ltd. is a high-tech enterprise specializing in the research and development, production and sales of insulating glass equipment, insulating glass production line, insulating glass automatic gluing machine, insulating glass processing equipment and export trade insulating glass machinery.Adhering to the professional, dedicated and dedicated working attitude, the company is constantly innovating and daring to challenge, has broken through one technical problem after another, and is striving to create a famous brand of insulating glass equipment respected by the global glass industry.

The company mainly produces research and development: insulating glass equipment, insulating glass production line, insulating glass machine, insulating glass machinery, insulating glass automatic gluing machine, automatic sealing line and other products.

Integrity comes from our responsibility and respect to customers, quality comes from our demanding and testing of each product, and innovation comes from countless explorations and tests before our products are put into production. Since its establishment, the company has insisted on quality and made the best insulating glass machines, which has won consistent praise from domestic and foreign customers.Our products are exported to more than ten countries and regions such as Europe, America, Africa and India.It is our greatest satisfaction to let China's mature high-end insulating glass equipment go abroad and get the recognition and trust of international users.

Letting the world fall in love with Made in China is a challenge, a feeling and a responsibility."Professionalism determines quality, strength creates brand" Jinan YBKE Machinery is willing to join hands with you to create brilliance!

The company mainly produces research and development: insulating glass equipment, insulating glass production line, insulating glass machine, insulating glass machinery, insulating glass automatic gluing machine, automatic sealing line and other products.

Integrity comes from our responsibility and respect to customers, quality comes from our demanding and testing of each product, and innovation comes from countless explorations and tests before our products are put into production. Since its establishment, the company has insisted on quality and made the best insulating glass machines, which has won consistent praise from domestic and foreign customers.Our products are exported to more than ten countries and regions such as Europe, America, Africa and India.It is our greatest satisfaction to let China's mature high-end insulating glass equipment go abroad and get the recognition and trust of international users.

Letting the world fall in love with Made in China is a challenge, a feeling and a responsibility."Professionalism determines quality, strength creates brand" Jinan YBKE Machinery is willing to join hands with you to create brilliance!

Exhibitions

Packing & Delivery

PACKING:

1.For full container load, usually wrapped in stretch films.

2.For open top container load, put on top grade plastic overcoat and tarpaulin to protect the equipment from moisture and water.

3.For less than container load, iron frame fixed or standard export plywood case.

DELIVERY:

* Small and few machines: in 5-10 days after receiving pre-payment.

* Big or many machines: more than 25 days after receiving pre-payment.

1.For full container load, usually wrapped in stretch films.

2.For open top container load, put on top grade plastic overcoat and tarpaulin to protect the equipment from moisture and water.

3.For less than container load, iron frame fixed or standard export plywood case.

DELIVERY:

* Small and few machines: in 5-10 days after receiving pre-payment.

* Big or many machines: more than 25 days after receiving pre-payment.

FAQ

Q1: What is your minimum order quantity?

A1: One set is ok for the order.

Q2: Is your company a manufacturer or trading company?

A2: We are a manufacturer of the glass machines, and we have our own factory and production team.

Q3: Can you do the production as customized?

A3: Yes, we can produce products according to your requirements.

Q4:If our price is higher than another company or factories?

A4: Please check the difference of the machine of parts ,service and guarantee, especially the machine inner electric parts, sometimes, if the machine have breakdown, the most reason is the machine inner electric parts problem, but we use the famous and reliable parts for the machines inside.

Q5:How to install our machines?

A5:We record the installation and debugging videos and will send you all the circuit diagrams. We could establish an after-sale service group of only your company after the machines arrives. After all we have had 1 year online installation and debugging experience, please be rest assured.

Q6: How can we guarantee quality?

A6:Always a pre-production sample before mass production. Always final Inspection before shipment.

Q7: How about the packing way?

A7: Usually we have the products packed with plastic film for full container and wooden box for less than container. We can also customize the package according to your need.

Q8:Can we get some discount or offer?

A8:Contact me to know more about it.

After Sales Service

PRE-SALES:

Free consultation; Patiently answer customer questions; Give reasonable suggestions according to customer conditions.

AFTER-SALES:

* Track production progress, deliver on time, strictly inspect before leaving the factory to ensure product quality;

* Charter and book space, arrange delivery smoothly, prepare customs clearance documents, and assist customers in import customs

clearance;

* Prepare equipment installation manuals and videos, after the equipment arrives, build the wechat group to help customers install

and operate online.

* If customers need on-site service, we have professional engineers who can go to the customer's site to guide installation

operations and staff training.

Free consultation; Patiently answer customer questions; Give reasonable suggestions according to customer conditions.

AFTER-SALES:

* Track production progress, deliver on time, strictly inspect before leaving the factory to ensure product quality;

* Charter and book space, arrange delivery smoothly, prepare customs clearance documents, and assist customers in import customs

clearance;

* Prepare equipment installation manuals and videos, after the equipment arrives, build the wechat group to help customers install

and operate online.

* If customers need on-site service, we have professional engineers who can go to the customer's site to guide installation

operations and staff training.

SIMILAR PRODUCTS