24 мм рубленая щелочестойкая нить из стекловолокна GFRC железобетонные

- Категория: Other Fiberglass Products >>>

- Поставщик: Ganzhou,Daye,Metallic,Fibres,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 1.9 $* | 1.56 $* |

| Jul-19-2025 | 1.93 $* | 1.5 $* |

| Jun-19-2025 | 1.37 $* | 1.0 $* |

| May-19-2025 | 1.9 $* | 1.40 $* |

| Apr-19-2025 | 1.22 $* | 1.1 $* |

| Mar-19-2025 | 1.48 $* | 1.88 $* |

| Feb-19-2025 | 1.14 $* | 1.20 $* |

| Jan-19-2025 | 1.71 $* | 1.75 $* |

Характеристики

24mm AR Chopped Alkali Resistant Glass Fibre Strand GFRC Glass Fiber Reinforced Concrete Fiberglass Products

Specification

24mm AR Chopped Alkali Resistant Glass Fibre Strand GFRC Glass Fiber Reinforced Concrete Fiberglass Products Details:

Product Name | 24mm AR Chopped Alkali Resistant Glass Fibre Strand GFRC Glass Fiber Reinforced Concrete Fiberglass Products |

Zircon | 16,5% |

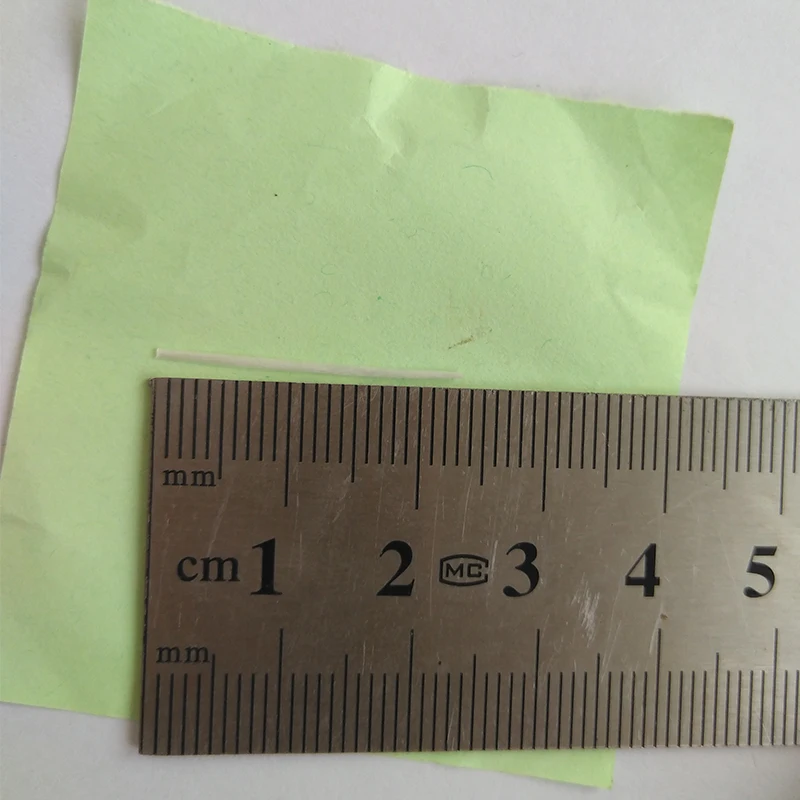

Diameter | 10-13.7 um |

Length | 12mm/19mm/24mm/36mm |

Tensile Strength | 1,700 MPa • 250 x 103 psi |

Type | AR Concrete Glass Fiber |

Density | 2.7 g/m3 |

Melt Point | 860°C • 1580°F |

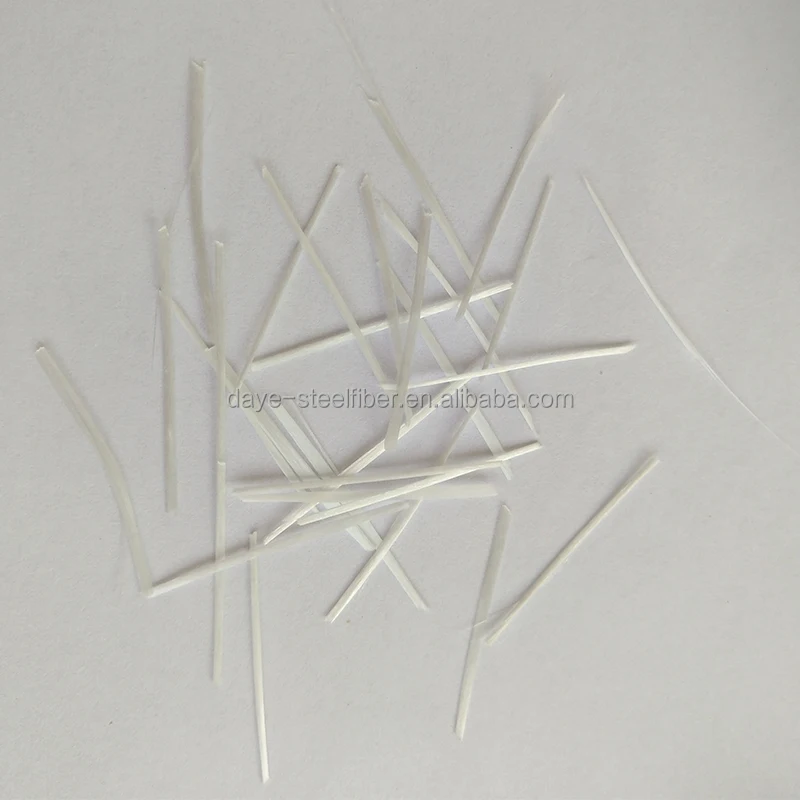

Color | White |

Property | Alkali Resistant, Assembled Roving |

Shape | Chopped Strand |

Material | Glass Fiber |

Chemical Resistance | Very High |

Modulus of Elasticity | 72 GPa •10x106 psi |

MOQ | 1 Kilogram |

Packing | 1 kg/small bag, 25 kg/big bag, 20000 kg/20ft container |

Product Description

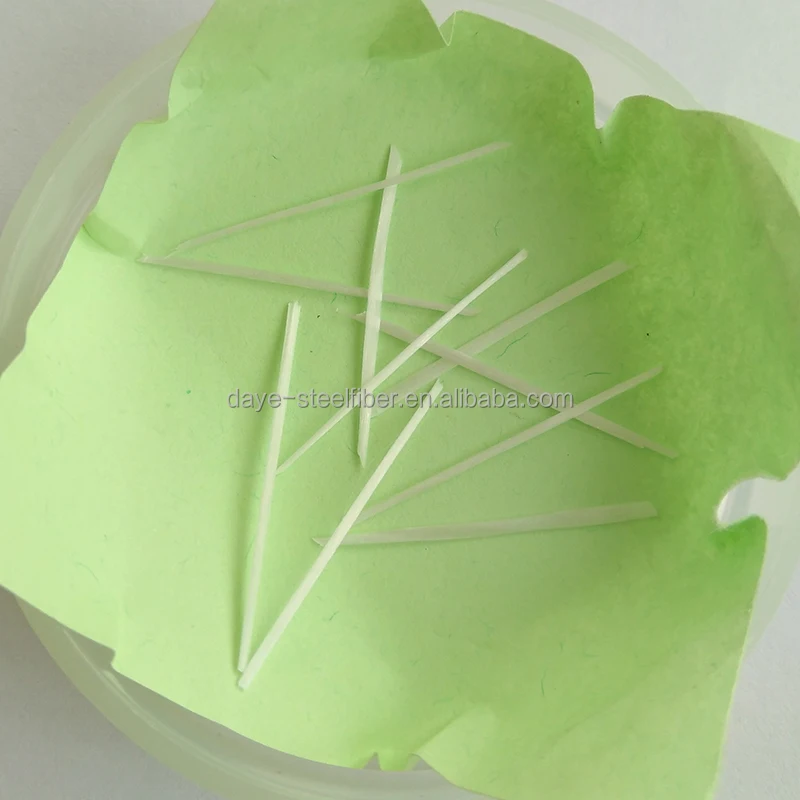

24mm AR Chopped Alkali Resistant Glass Fibre Strand GFRC Glass Fiber Reinforced Concrete Fiberglass Products Pictures:

24mm AR Chopped Alkali Resistant Glass Fibre Strand GFRC Glass Fiber Reinforced Concrete Fiberglass Products Features:

Fiberglass is an Alkali Resistant glass fiber assembled roving designed for use in the manufacture of glass fiber reinforced concrete (GRC) composites by both premix and simultaneous spray methods.

Dosage:

Fiberglass rovings are used in GRC manufacturing processes with purpose-made GRC equipment. The recommended dosage in sprayed GRC is 5% by weight. The recommended dosage in premix GRC is 3% by

weight.

Economic advantages:

1. Good unwinding

2. Easy chopping

3. High split efficiency

4. Safe and easy to handle

5. Very easy incorporation into the matrix

6. Ideal for use with complicated profiles

7. Excellent reproduction of detail

8. Excellent mechanical performance

9. Makes highly durable GRC elements

10. Suitable for both premix and spray

2. Easy chopping

3. High split efficiency

4. Safe and easy to handle

5. Very easy incorporation into the matrix

6. Ideal for use with complicated profiles

7. Excellent reproduction of detail

8. Excellent mechanical performance

9. Makes highly durable GRC elements

10. Suitable for both premix and spray

11. Alkali resistant glass

Application:

In the premix process, fiberglass is chopped into small strands with high abrasion resistance. The fiber remains integral and this provides easy incorporation into the matrices and efficient workability. Its new sizing technology reduces the water absorption of the fiber strand, allowing a reduction in the water content of the matrix, or an increase in the fiber content. In the spray process, fibreglass has good split efficiency and easy chopping with low fuzz generation. Its hydrophobic behavior makes the mix more fluid and that ensures better compaction and easier release of trapped air.Packing and Storage:

1. 7 kg/bag, 175 kg/pallet, 3500 kg/20ft container, 9100 kg/40ft container.

2. Fiberglass rovings are protected by a shrink-wrap polythene film, open at the top which should not be removed when the product is in use. Rovings are packed on pallets either with or without carton boxes.

3. Fibreglass rovings should be stored away from heat and moisture, and in their original packaging. The best conditions are:

a) Temperature: 15ºC – 35ºC.

b) Humidity: 35% – 65%.

4. If the product is stored at lower temperatures it is advisable to condition it in the workshop for at least 24 hours before use, to prevent condensation.

3. Fibreglass rovings should be stored away from heat and moisture, and in their original packaging. The best conditions are:

a) Temperature: 15ºC – 35ºC.

b) Humidity: 35% – 65%.

4. If the product is stored at lower temperatures it is advisable to condition it in the workshop for at least 24 hours before use, to prevent condensation.

24mm AR Chopped Alkali Resistant Glass Fibre Strand GFRC Glass Fiber Reinforced Concrete Fiberglass Products. industrialflooring concrete steelfiber SFRC UHPC concreto flooring engineering construccion construction concrete concreteproducts concreteroad microrebar construction constructionlife building builder buildingroads moderninfrastructure fiberconcrete

Company Profile

FAQ

Q: Are you factory?

A: Yes, exactly. We are specializing in building items and related machines since 2002. We are located in Ganzhou City and have 20000 M2 production base. All stuff of Daye company are always glad ready to service you! Daye Fiber manufactures steel fibers that plays a strengthening role in concrete. Steel fibers are widely used in important engineering components. Our fibre can greatly increase the tensile and flexural strength of UHPC. These fibers comply with the standard of ASTM A820. Since we are a factory, we can produce all kinds of steel fiber. Our production rate is 10 tons per day. We have attained ISO and CE certificates. More information, please visit our website https://daye-steelfiber.en.alibaba.com

Q: Is trial order acceptable?

A: Yes, a trial order with lower MOQ is always accepted for quality and market evaluation.

A: Yes, exactly. We are specializing in building items and related machines since 2002. We are located in Ganzhou City and have 20000 M2 production base. All stuff of Daye company are always glad ready to service you! Daye Fiber manufactures steel fibers that plays a strengthening role in concrete. Steel fibers are widely used in important engineering components. Our fibre can greatly increase the tensile and flexural strength of UHPC. These fibers comply with the standard of ASTM A820. Since we are a factory, we can produce all kinds of steel fiber. Our production rate is 10 tons per day. We have attained ISO and CE certificates. More information, please visit our website https://daye-steelfiber.en.alibaba.com

Q: Is trial order acceptable?

A: Yes, a trial order with lower MOQ is always accepted for quality and market evaluation.

Q: When can I receive my products?

A: Sample order: 1 - 3 days; Mass production: 15-20 workdays .

Shipping: 1) 7-9 workdays by Express.

2) 9-11 workdays by Air.

3) 20-25 workdays by Sea.

Shipping: 1) 7-9 workdays by Express.

2) 9-11 workdays by Air.

3) 20-25 workdays by Sea.

Q: What kinds of fibers can you supply?

A: We manufacture fibers according customer requirement. Steel fiber types includes,

a) Hooked ends steel fiber

b) Flat head steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Xorex steel fiber

f) Micro-steel fiber

g) stainless steel fiber

Q: What are applications of Daye steel fiber?

A: a) Tunnel pre-treatment(primary support)

b) Tunnel forming(permanent lining)

c) Slope stabilization

d) Ditch excavation support

e) Industrial floor

f) Precast concrete element

g) Concrete restoration

h) High performance concrete

Q: What are technical advantages of Daye steel fiber?

A: a) Improve mechanical performance of concrete

b) Provide uniform distribution throughout concrete with excellent mixing

c) No balling or caking by adopt correct mixing method

Q: What are economic benefits of DAYE steel fiber?

A: a) Replace of rebar mesh

b) Reduce concrete volume

c) Save construction time and cost

d) Reduce excavation volume

e) Available for jointless floor.

A: We manufacture fibers according customer requirement. Steel fiber types includes,

a) Hooked ends steel fiber

b) Flat head steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Xorex steel fiber

f) Micro-steel fiber

g) stainless steel fiber

Q: What are applications of Daye steel fiber?

A: a) Tunnel pre-treatment(primary support)

b) Tunnel forming(permanent lining)

c) Slope stabilization

d) Ditch excavation support

e) Industrial floor

f) Precast concrete element

g) Concrete restoration

h) High performance concrete

Q: What are technical advantages of Daye steel fiber?

A: a) Improve mechanical performance of concrete

b) Provide uniform distribution throughout concrete with excellent mixing

c) No balling or caking by adopt correct mixing method

Q: What are economic benefits of DAYE steel fiber?

A: a) Replace of rebar mesh

b) Reduce concrete volume

c) Save construction time and cost

d) Reduce excavation volume

e) Available for jointless floor.

Похожие товары

Стекловолоконные обрезки/Отходная пряжа для гипсокартона

US $0.70-$0.80

Гибридные ткани из базальтового волокна

US $3.80-$4.00

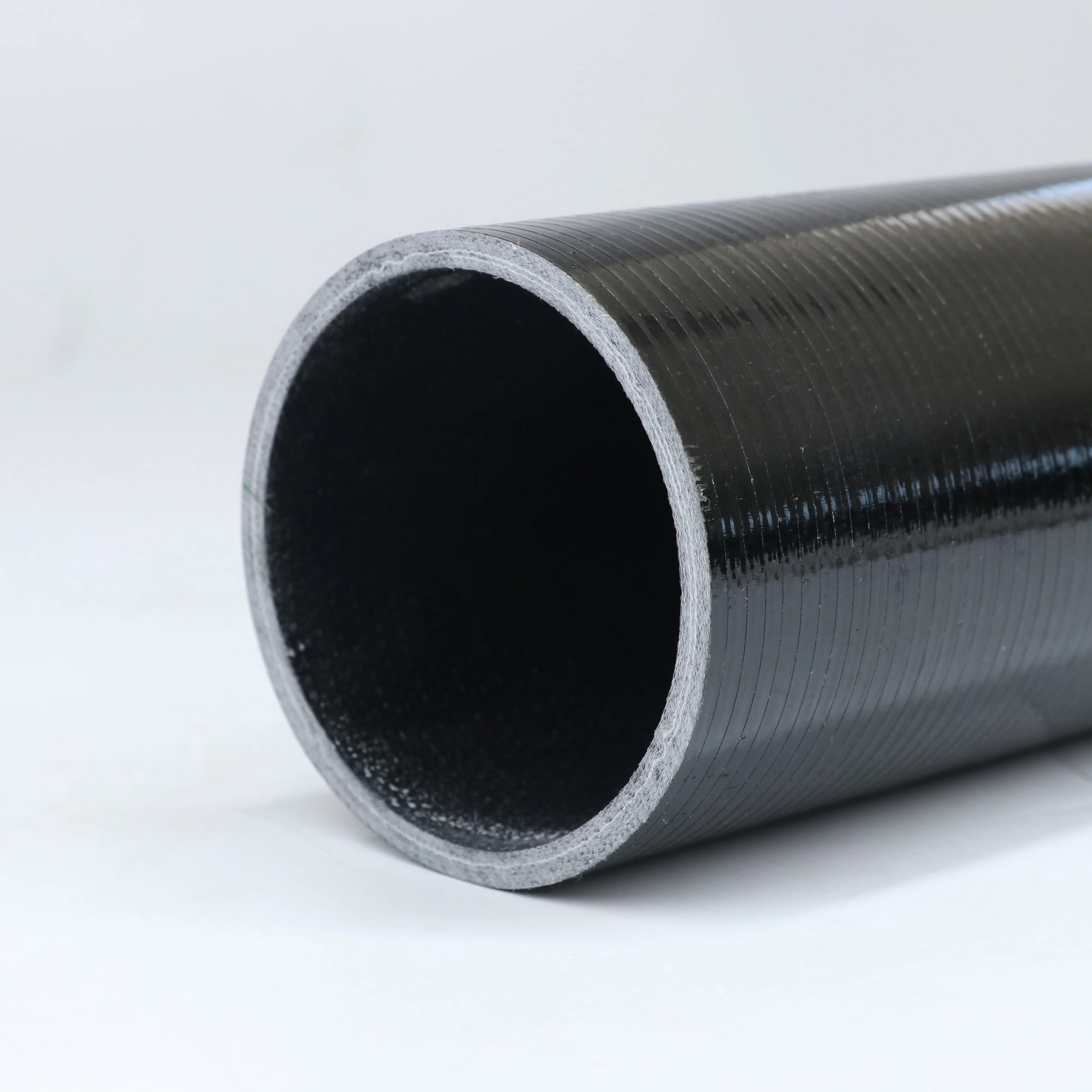

Высокопрочная термостойкая Стекловолоконная труба/столб/труба

US $19.00-$24.00