Машина для производства стекла с

- Категория: Glass Production Machinery >>>

- Поставщик: Jinan,Ybke,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 8925.89 $* | 9371.1 $* |

| Aug-17-2025 | 8850.7 $* | 9293.83 $* |

| Jul-17-2025 | 7425.3 $* | 7796.32 $* |

| Jun-17-2025 | 8700.70 $* | 9135.3 $* |

| May-17-2025 | 7575.92 $* | 7954.30 $* |

| Apr-17-2025 | 8550.92 $* | 8978.97 $* |

| Mar-17-2025 | 8475.26 $* | 8899.28 $* |

| Feb-17-2025 | 8400.81 $* | 8820.16 $* |

| Jan-17-2025 | 8325.72 $* | 8741.47 $* |

Характеристики

Product Description

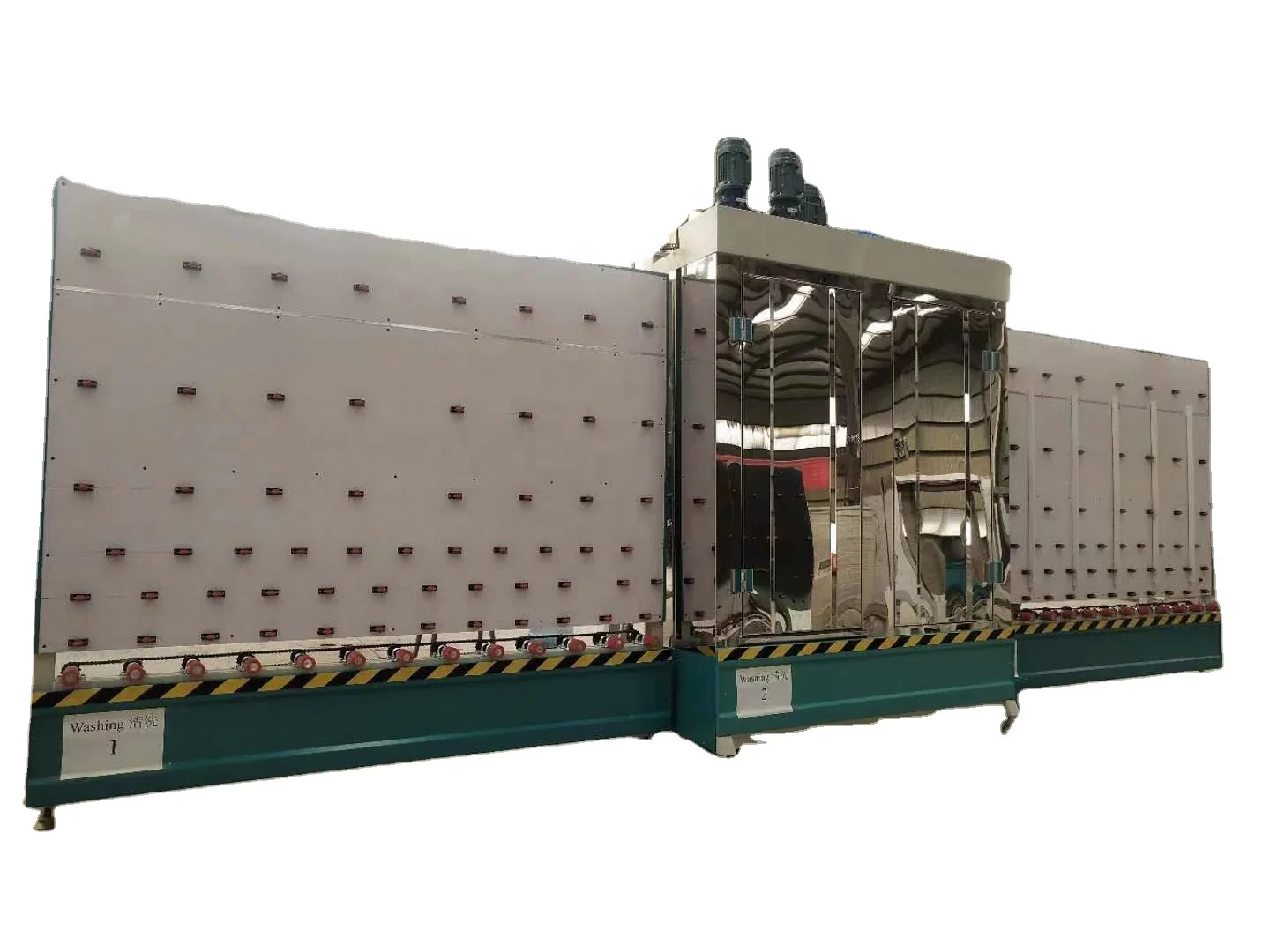

Double Glazing Glass Machine glass production machinery

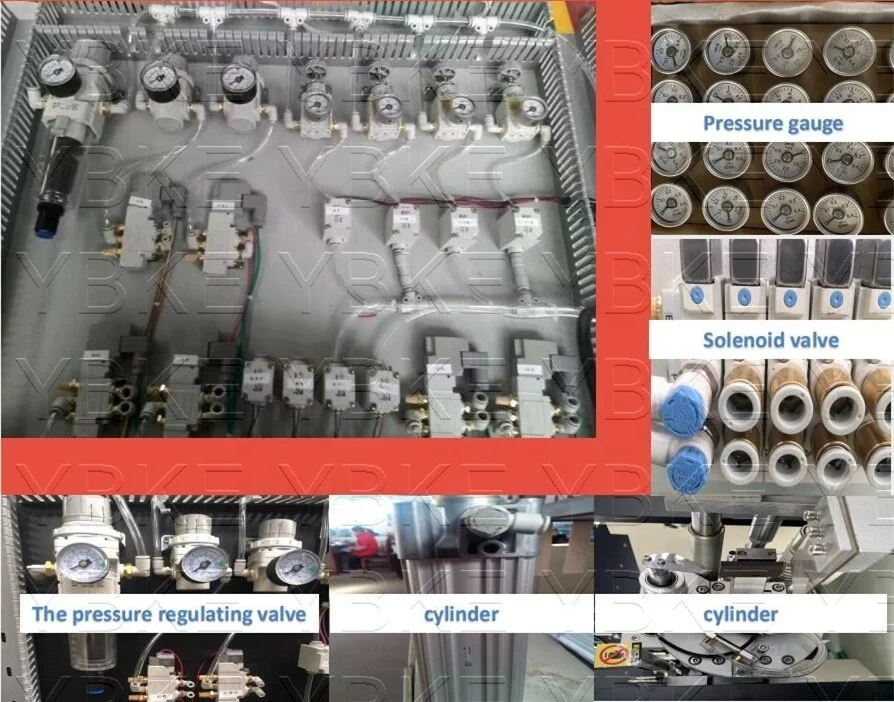

The glass washing machine is a special equipment for cleaning and drying the glass surface before the deep processing processes such as mirror making, vacuum coating, tempering, hot bending, and insulating glass assembling. The glass washing machine is mainly composed of transmission system, scrubbing, water rinsing, pure water rinsing, cold and hot air drying, and electric control system.

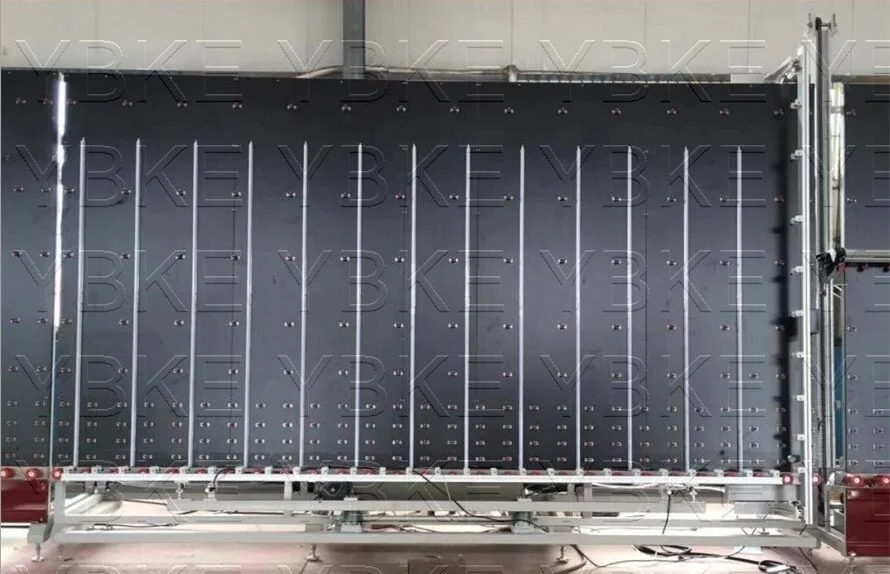

a. The whole line is composed of feeding part, glass washing and drying part, lamp inspection part,

glass conveyor part, aluminum frame locating part, flat (roller) press part, tilting part.

b. Low-E Insulating Glass Production Line, soft low-e brush installed, it can process low-e glass.

c. It can make triple insulating glass, that is three layers insulating glass and shaped insulating glass.

d. Washing and drying part with full stainless steel.

e. Heating device, auto heat the water in cold weather.

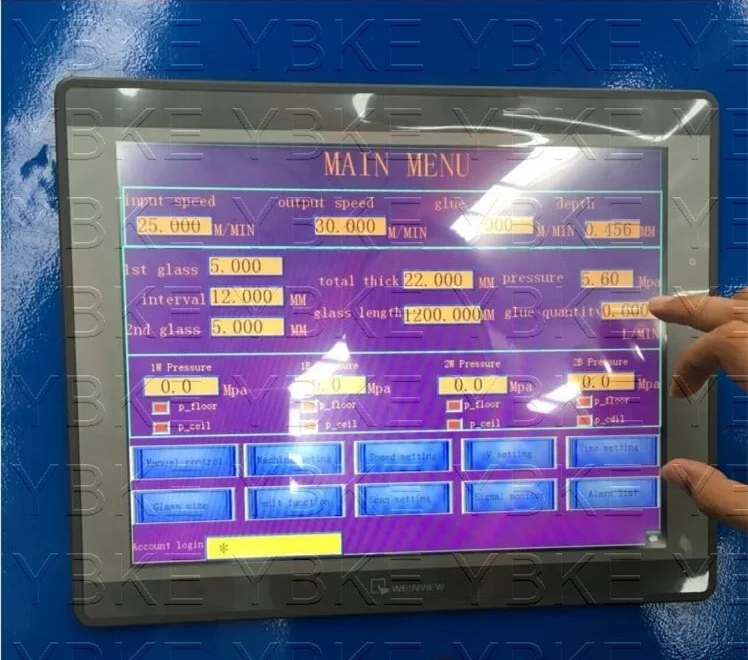

f. Man-machine interface, easy to operate.

a. The whole line is composed of feeding part, glass washing and drying part, lamp inspection part,

glass conveyor part, aluminum frame locating part, flat (roller) press part, tilting part.

b. Low-E Insulating Glass Production Line, soft low-e brush installed, it can process low-e glass.

c. It can make triple insulating glass, that is three layers insulating glass and shaped insulating glass.

d. Washing and drying part with full stainless steel.

e. Heating device, auto heat the water in cold weather.

f. Man-machine interface, easy to operate.

Specification

item | value |

Voltage | 380v 50hz |

Power | 20kw |

Dimension(L*W*H) | 15600*2350*3000mm |

Weight | 2500kg |

Warranty | 1 Year |

Glass Thickness | 3-18mm |

min. glass size | 300X400mm |

max. in washing section | 12m/min |

insulating glass thickness | 50mm |

Packing & Delivery

PACKING:

1.For full container load, usually wrapped in stretch films.

2.For open top container load, put on top grade plastic overcoat and tarpaulin to protect the equipment from moisture and water.

3.For less than container load, iron frame fixed or standard export plywood case.

DELIVERY:

* Small and few machines: in 5-10 days after receiving pre-payment.

* Big or many machines: more than 25 days after receiving pre-payment.

Our Certificate

The glass washing machines, glass cutting machines, aerators, molecular sieve filling machines and other glass manufacturing equipment we produce have complete product quality certificates.

Company Profile

Jinan YBKE Machinery Co., LTD. Is a professional factory in insulating glass processing equipment research and development, production and sales, export trade of high-tech enterprises. Companies adhering to the professional, focused, concentrate on work attitude,continuous innovation, and courage to challenge.Broke through one after another technical problem. Are trying to create a global glass industry respected brands.

Products are exported to Europe and the United States, Africa, India and other dozens of countries and regions.And get the praise and trust from international users, "Professional decision quality, Strength creates brand YBKE is willing to work with you hand in hand to create brilliant!

Products are exported to Europe and the United States, Africa, India and other dozens of countries and regions.And get the praise and trust from international users, "Professional decision quality, Strength creates brand YBKE is willing to work with you hand in hand to create brilliant!

FAQ

1.Question: How about the service ?

(1).Reply it at once in WhatsAPP,if by email,it will be reply within 12 hours.

(2).24 hours for after-sale serive

(3).more than 11years experience in this kind machine field

(4).fluent english ,communication barrier free. Point-to-point service help you solve the problems timely.

2. When can we arrange shippment?

(1)We usually arrange shippment within 15 days after getting deopsit,

(2)but customized machines should be more than 25 days.

3.What you can do if my machines have problems?

(1) We can send you free components to you if your machines are in guarantee time.

(2) We can send our engineers to repair your machines

4.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

(1).Reply it at once in WhatsAPP,if by email,it will be reply within 12 hours.

(2).24 hours for after-sale serive

(3).more than 11years experience in this kind machine field

(4).fluent english ,communication barrier free. Point-to-point service help you solve the problems timely.

2. When can we arrange shippment?

(1)We usually arrange shippment within 15 days after getting deopsit,

(2)but customized machines should be more than 25 days.

3.What you can do if my machines have problems?

(1) We can send you free components to you if your machines are in guarantee time.

(2) We can send our engineers to repair your machines

4.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

Store recommendation

More Details

Installation and Adjustment

1 On-site conditions: 380V AC power supply, industrial clean water source, drainage ditches, and a clean and dust-free site should be available.

2 Connect each transmission system according to relevant standards.

3 Clean the water tank before filling it with water.

4 After installation and adjustment, test run according to the operation sequence specified in this manual.

5 After drying, there will be a small amount of water droplets on the rear edge of the glass. If there are higher requirements, you need to entrust the design separately.

6 When cleaning the smallest size glass, do not place it parallel to the conveying roller

2 Connect each transmission system according to relevant standards.

3 Clean the water tank before filling it with water.

4 After installation and adjustment, test run according to the operation sequence specified in this manual.

5 After drying, there will be a small amount of water droplets on the rear edge of the glass. If there are higher requirements, you need to entrust the design separately.

6 When cleaning the smallest size glass, do not place it parallel to the conveying roller