Машина для экстракции

- Категория: Chemical Machinery >>>

- Поставщик: Wenzhou,Jinbang,Light,Industry,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 14280.31 $* | 14994.17 $* |

| Aug-16-2025 | 14160.45 $* | 14868.5 $* |

| Jul-16-2025 | 11880.33 $* | 12474.27 $* |

| Jun-16-2025 | 13920.61 $* | 14616.94 $* |

| May-16-2025 | 12120.51 $* | 12726.45 $* |

| Apr-16-2025 | 13680.39 $* | 14364.72 $* |

| Mar-16-2025 | 13560.2 $* | 14238.31 $* |

| Feb-16-2025 | 13440.6 $* | 14112.47 $* |

| Jan-16-2025 | 13320.54 $* | 13986.91 $* |

Характеристики

The Marked Prices Of Our Products Are All Range Prices Of The Entire Product Series.

If You Need a Detailed Quotation, Please Send An Inquiry At The Bottom Of The Page.

Application

plant powder extraction machine Licorice extract machine

The production process of licorice extract typically involves several steps. Here is a general outline of the process:

Raw Material Selection: High-quality licorice roots are selected as the raw material for extraction. Licorice roots contain glycyrrhizin, the main active compound responsible for the sweet flavor properties of licorice.

Raw Material Selection: High-quality licorice roots are selected as the raw material for extraction. Licorice roots contain glycyrrhizin, the main active compound responsible for the sweet flavor properties of licorice.

Products Description

1. Preprocessing:

Cleaning and Washing: The licorice roots are thoroughly cleaned and washed to remove any dirt, debris, or impurities.

Cutting and Grinding: The cleaned licorice roots are cut into smaller pieces or ground into a coarse powder. This increases the surface area and facilitates the extraction process.

Cutting and Grinding: The cleaned licorice roots are cut into smaller pieces or ground into a coarse powder. This increases the surface area and facilitates the extraction process.

2. Extraction tank(Stirred):

The cut or ground licorice roots are mixed with a suitable solvent, typically water or ethanol. The extraction process can be carried out through various methods, including maceration, percolation, or reflux extraction. The solvent helps to dissolve and extract the active compounds, including glycyrrhizin and other beneficial constituents.

3. Concentrator:

The filtered extract is concentrated to increase the concentration of active compounds. This can be achieved through methods like evaporation or vacuum distillation, which remove the solvent and concentrate the desired constituents.

4. Purification:

Depending on the extraction method and desired purity, further purification steps may be employed. These can include techniques like precipitation, adsorption, or chromatography to isolate and purify specific compounds.

5. Drying:

The concentrated and purified extract is dried to remove any remaining moisture. This can be achieved through methods such as spray drying, freeze-drying, or vacuum drying. Drying helps to stabilize the extract and enhance its shelf life.

Accessories:

The tank is equipped with CIP cleaning automatic rotating spray ball, temperature gauge, pressure gauge, explosion-proof sightglass lamp, sight glass, quickopening feeding port, etc., to ensure easy operation and meet GMP standards. The inner cylinder of the equipment is made of 304 and 316L.

Product Paramenters

Series technical parametes | TQ-1 | TQ-2 | TQ-3 | TQ-4 | TQ-5 | TQ-6 |

Volume(L) | 1200 | 2300 | 3200 | 6300 | 8500 | 11000 |

Tank design pressure (MPA) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

Compressed air pressure (MPA) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

Feed port diameter (mm) | 400 | 400 | 400 | 500 | 500 | 500 |

Heating area (m²) | 3.0 | 4.7 | 6.0 | 7.5 | 9.5 | 12 |

Condensation area (m²) | 4 | 4 | 5 | 5 | 8 | 10 |

Coling area (m²) | 1 | 1 | 1 | 2 | 2 | 3 |

Filtration area (m²) | 3 | 3 | 3 | 5 | 5 | 6 |

Slag gate area (m²) | 800 | 800 | 800 | 1000 | 1000 | 1000 |

Energy consumption (kg/h) | 245 | 325 | 345 | 645 | 720 | 850 |

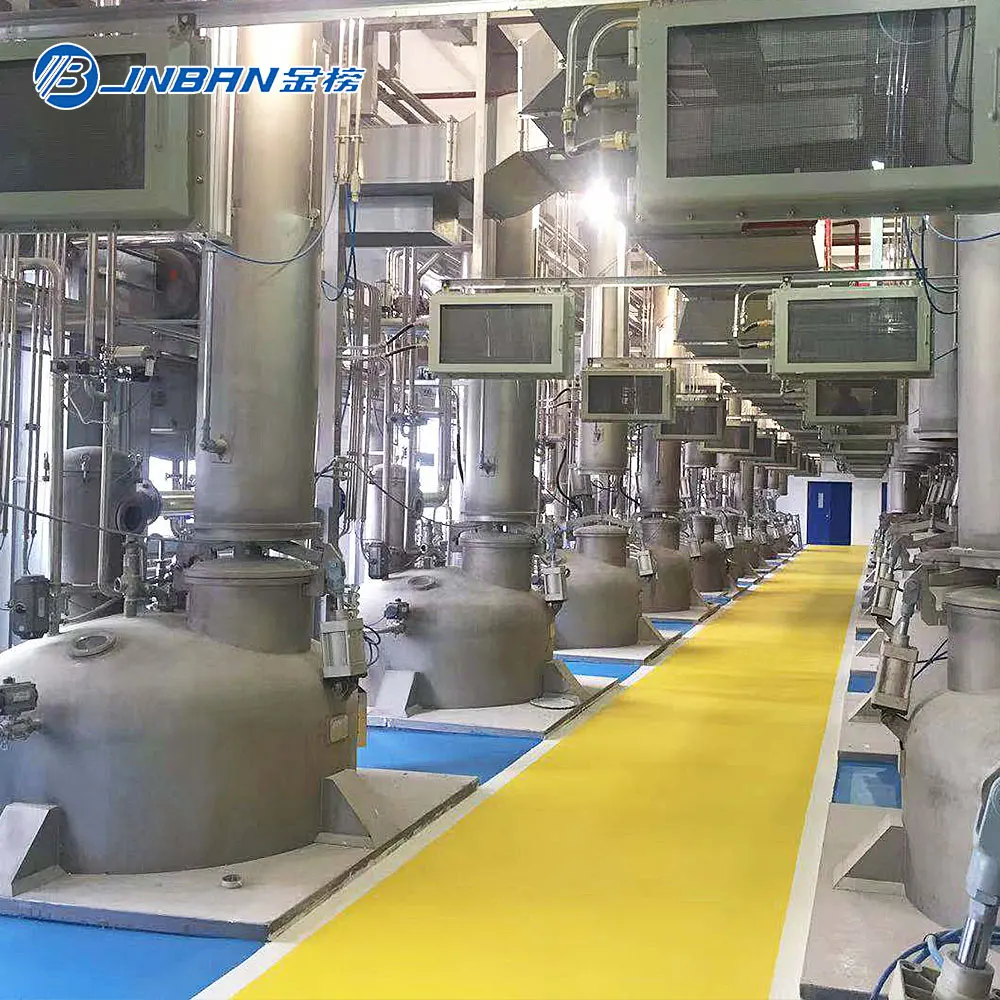

Successful Project

Herbal Project

Herbal Project

Essential Oil Project

Essential Oil Project

Herbal Project

CBD Oil Project

FAQ

Q1:What Factors Affect The Quality Of Plant Extract From Plant Extraction Machine?

The quality of the plant extract may directly or indirectly be proportional to the following factors:

●Raw material; Pay specific attention to the variety of the plant because even the slightest variation could shift the extract

quality.Even the particular plant variety would be affected by climatic conditions, geographical locations, cultivations, and so on.

Most important of all, finding the balance between the specific needs is quite challenging.As such, we are guaranteeing quality with the raw materials is struct.

●Quality of the solvent; Having the best choice solvent would result in high-quality extract and vice versa.

The quality of the plant extract may directly or indirectly be proportional to the following factors:

●Raw material; Pay specific attention to the variety of the plant because even the slightest variation could shift the extract

quality.Even the particular plant variety would be affected by climatic conditions, geographical locations, cultivations, and so on.

Most important of all, finding the balance between the specific needs is quite challenging.As such, we are guaranteeing quality with the raw materials is struct.

●Quality of the solvent; Having the best choice solvent would result in high-quality extract and vice versa.

●Selected plant extraction machine; The operating principle and operation hugely determine the quality level of the extract.

So you have to pay attention to the machine specification.

It is prudent to buy from a reputable seller with years of experience and quality.

Q2:What Heat Sources can you Employ for your Belt dryer?

● Steam

● Hot water

● Hot oil

Q3:Purchasing process

●Consultation, test, technical scheme determination, business negotiation, contract.

Q4:How long is the guarantee period

●1 year after finishing installation and commissioning.

So you have to pay attention to the machine specification.

It is prudent to buy from a reputable seller with years of experience and quality.

Q2:What Heat Sources can you Employ for your Belt dryer?

● Steam

● Hot water

● Hot oil

Q3:Purchasing process

●Consultation, test, technical scheme determination, business negotiation, contract.

Q4:How long is the guarantee period

●1 year after finishing installation and commissioning.

Company Profile

Certifications

Hot products