1800Ton 18000KnN Автозапчасти автомобильные запчасти автомобильный бампер пластиковая машина для

- Категория: Injection Molding Machines >>>

- Поставщик: Ningbo,Bocheng,Intelligent,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 351050.3 $* | 368603.50 $* |

| Aug-16-2025 | 348100.75 $* | 365505.25 $* |

| Jul-16-2025 | 292050.96 $* | 306653.3 $* |

| Jun-16-2025 | 342200.31 $* | 359310.40 $* |

| May-16-2025 | 297950.43 $* | 312848.21 $* |

| Apr-16-2025 | 336300.87 $* | 353115.11 $* |

| Mar-16-2025 | 333350.87 $* | 350018.25 $* |

| Feb-16-2025 | 330400.72 $* | 346920.11 $* |

| Jan-16-2025 | 327450.68 $* | 343823.42 $* |

Характеристики

Product Description

SK SERIES MECHANICAL VERTICAL-COMPRESSION STRUCTURE

Resilient mould thickness and long displacement stroke

Reasonable oil circuit design, which is more energy-saving,

improves the operating speed and can save 2%-6% raw

materials from 90% products for the customers.

improves the operating speed and can save 2%-6% raw

materials from 90% products for the customers.

Reinforced molding board, thicker pull rod, high rigidity frame, with more stable operation state and longer service life.

TRADITIONAL STRUCTURE

Mechanical Vertical-Compression Structure Applied by Sunbun Injection Molding Machine

1.100% clamping use ratio, 10%-20% higher than that of traditional structures;

2. Less fins on the finished products;

3. 2%-6% raw materials saved from production than that of traditional structures;

4. Effective protection for the mould, molding board, and pull rod;

5. A opening stroke 10%-20% longer than that of traditional structures;

6. Less deformation caused by cooling of the products.

2. Less fins on the finished products;

3. 2%-6% raw materials saved from production than that of traditional structures;

4. Effective protection for the mould, molding board, and pull rod;

5. A opening stroke 10%-20% longer than that of traditional structures;

6. Less deformation caused by cooling of the products.

Specification

Injection Part | Item/type | Unit | SK1800 / C180000 | ||||

Screw type | A | B | C | ||||

Screw diameter | mm | 130 | 140 | 150 | |||

Screw diame-ter ratio | L/D | 23.7 | 22 | 20.5 | |||

Theoretical injection volume | cm³ | 9286 | 10770 | 12363 | |||

Injection volume (PS) | g | 8450 | 9800 | 11251 | |||

Maximum rate for inject-ion to air | cm³/s | 1171 | 1358 | 1560 | |||

Injection pressure | MPa | 193 | 166 | 145 | |||

Injection stroke | mm | 700 | |||||

Maximum injection speed | mm/s | 77 | |||||

Maximal Rotational Speed of Screw | r/min | 91 | |||||

Clamping Part | Clamp Tonnage | KN | 18000 | ||||

Toggle stroke | mm | 1720 | |||||

Distance between tie bars | mmxmm | 1620x1460 | |||||

Maximum mould height | mm | 1500 | |||||

Minimum mould height | mm | 530 | |||||

Ejection stroke | mm | 400 | |||||

Ejector force forward | KN | 332 | |||||

Ejector force backard | KN | 226 | |||||

Amount of die thimble | Pcs | 1+24 | |||||

System pressure | Mpa | 17.5 | |||||

Motor power | KW | 45+45+45 | |||||

Heater power | KW | 80 | |||||

Quantity of temperature-control zones | 1+6 | ||||||

Bucket capacity | KG | 200 | |||||

Oil tank capacity | L | 2200 | |||||

Boundary dimension(L×W×H) | m | 15.5x3.2x3.5 | |||||

Machine weight | Ton | 128 | |||||

INJECTION SYSTEM

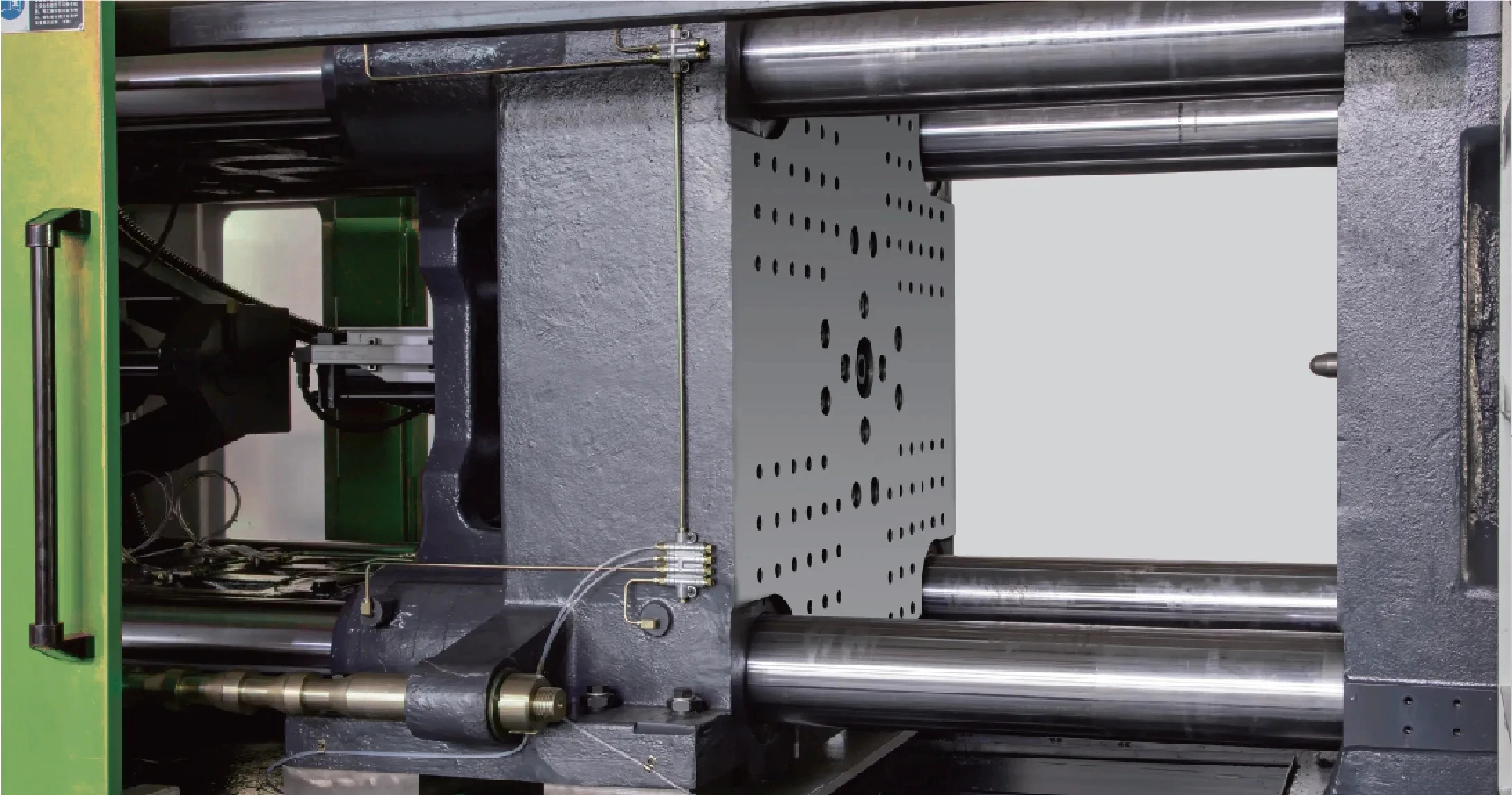

CLAMPING SYSTEM

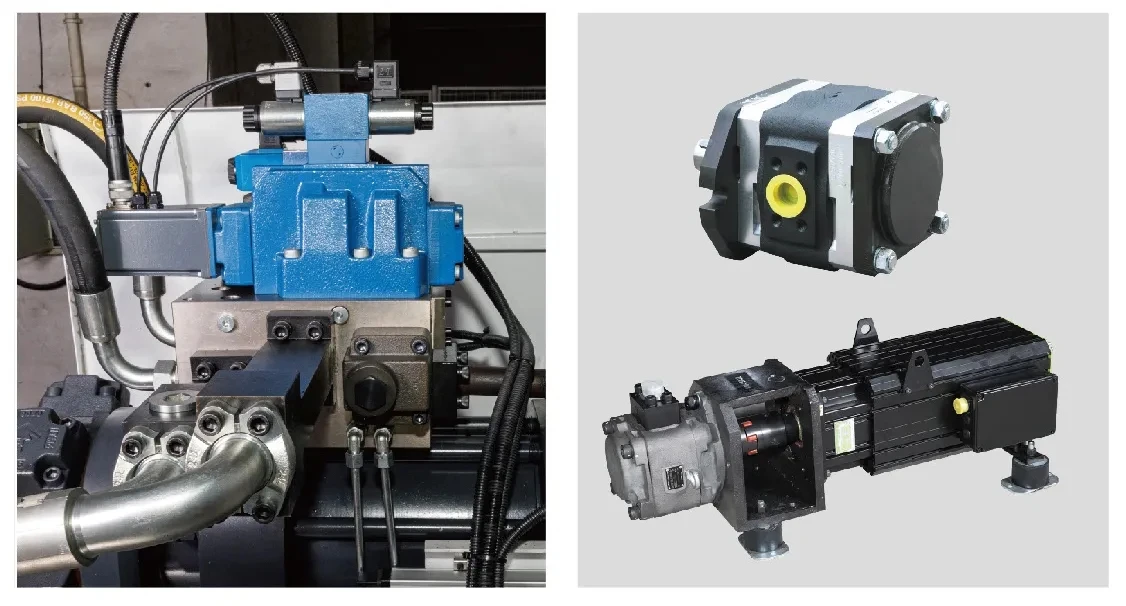

HYDRAULIC SYSTEM

ELECTRONIC CONTROL SYSTEM

Application

Auto parts

Sanitation products

Medical field

Black and white household appliance

Toy industry

Home appliances

Powder box

Lipstick

Shoes material products

Packing & Delivery

Company Profile

Zhejiang Sunbun Intelligent Equipment Co., Ltd (Sunbun Machine)is the branch of Sunbun Group. Which Founded in 1993. Through nearly 30 years development Sunbun Group now have Wenzhou, Hangzhou, Shanghai , Xuzhou ,Quzhou 7 Production Base.

Group specialized in scientific research , design and production of hydraulic components , Valve ,Systems and actuators of

construction machinery. As national level high-tech enterprise. Sunbun group have participated in R&D and implementation of “China Torch Program” and “Spark Program”

Sunbun Machine established in 2000 mainly engages in R&D manufacture and sales of automation intelligent equipment and plastic injection molding machine etc. Through the unceasing innovation and development of more than 30 researchers and technicians Sunbun succeeded in launching various injection molding machines and some special use machine (e.g. Medical machine , Sole Making Machine, Tie making machine , Pen Making machine )

Group specialized in scientific research , design and production of hydraulic components , Valve ,Systems and actuators of

construction machinery. As national level high-tech enterprise. Sunbun group have participated in R&D and implementation of “China Torch Program” and “Spark Program”

Sunbun Machine established in 2000 mainly engages in R&D manufacture and sales of automation intelligent equipment and plastic injection molding machine etc. Through the unceasing innovation and development of more than 30 researchers and technicians Sunbun succeeded in launching various injection molding machines and some special use machine (e.g. Medical machine , Sole Making Machine, Tie making machine , Pen Making machine )

FAQ

Q1:What is your machine warrenty ?

A1: For the whole machine we provide 12 month , For the Pull Rod. We provie 24 month For the Mold Platen we provide 36 month

Q2: Are you provide auxiliary machine for the whole project ?

A2: Yes We provide many brand auxiliary machine also provide turnkey solustation.

Q3: How about the quality control in your factory?

A3: We have full set testing control files. Every part testing have full record . Before shipment small machine need shot over 7000 times. and big machine shot for 5000 times.

Q4: What is your lead time ?

A4: If we have stock we can deliver in 3 days. For normal production we need around 30-60 Days depends on machine tonnage.

Q5 : Mold trial will be available in your factory ?

A5: Yes, Customer can send the mold to our factory and test. If clients buy mold together, we will testing and send sample to clients for final confirmation then shipment.

Q6 . Do you provide any spare parts with machine?

A6: Yes, We will provide one set standard spare parts to customer including heater ,filter, noozle ,tool box etc.

Q7: What about your after sales service

A7: we have many experience technical engineers for oversea service, they would help you install machine and provide basic training.

Q2: Are you provide auxiliary machine for the whole project ?

A2: Yes We provide many brand auxiliary machine also provide turnkey solustation.

Q3: How about the quality control in your factory?

A3: We have full set testing control files. Every part testing have full record . Before shipment small machine need shot over 7000 times. and big machine shot for 5000 times.

Q4: What is your lead time ?

A4: If we have stock we can deliver in 3 days. For normal production we need around 30-60 Days depends on machine tonnage.

Q5 : Mold trial will be available in your factory ?

A5: Yes, Customer can send the mold to our factory and test. If clients buy mold together, we will testing and send sample to clients for final confirmation then shipment.

Q6 . Do you provide any spare parts with machine?

A6: Yes, We will provide one set standard spare parts to customer including heater ,filter, noozle ,tool box etc.

Q7: What about your after sales service

A7: we have many experience technical engineers for oversea service, they would help you install machine and provide basic training.