Литье из

- Категория: Fabrication Services >>>

- Поставщик: Changzhou,Paipu,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.13 $* | 0.69 $* |

| Aug-20-2025 | 0.81 $* | 0.59 $* |

| Jul-20-2025 | 0.2 $* | 0.57 $* |

| Jun-20-2025 | 0.18 $* | 0.84 $* |

| May-20-2025 | 0.21 $* | 0.39 $* |

| Apr-20-2025 | 0.28 $* | 0.50 $* |

| Mar-20-2025 | 0.85 $* | 0.62 $* |

| Feb-20-2025 | 0.0 $* | 0.38 $* |

| Jan-20-2025 | 0.46 $* | 0.50 $* |

Характеристики

The products shown here is only to present the scope of our business activities. We can manufacture no standard parts according to your drawing or sample.

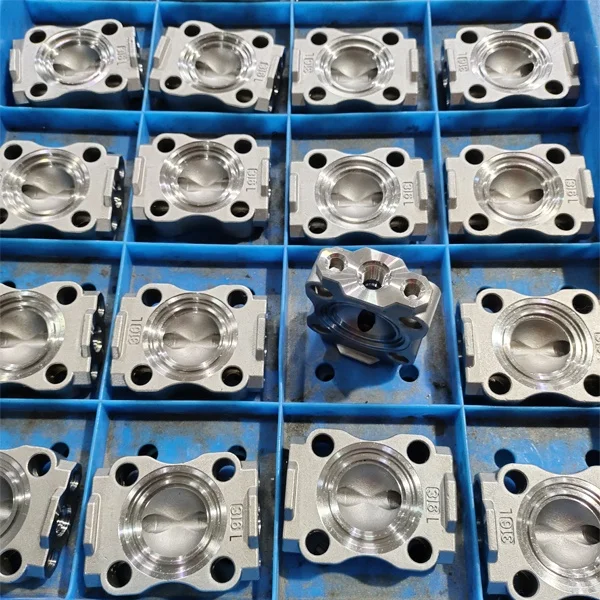

Aluminum brass bronze casting custom precision investment casting parts stainless steel casting foundry lost wax casting service

We can make brass/steel/stainless steel/aluminum castings with Sand Cast Process, Investment Cast Process, Lost Wax Cast Process, Water Glass Cast Process,Gravity Cast Process.

Gravity Casting / Investment Castng / Lost Wax Casting / Water Glass Casting

1, Casting details

Mainly Material | stainless steel, carbon steel, steel, aluminium, brass, bronze, copper |

Process | investment casting, lost wax casting, silica sol casting. water glass casting |

Casting tolerance | CT4-CT6 (GB/T 6414),CT7-CT9 (GB/T 6414) |

Standard | AISI, ANSI, ASTM, JIS, GB, ISO, DIN |

Certificate | TS16949,SGS, ISO, or as your requirement to do test by the third party |

Machining | tapping, milling, grinding, drilling, cnc machining |

Tolerance | as drawing requirement |

Surface treatment | polishing,mirror polishing, electrogalvanizing, sandblasting, shot blasting |

Heat treatment | quenching and tempering, annealing, normalizing |

Casting Roughness | Ra 1.6-Ra12.5 |

• Agricultural equipment | • Armament | • Automobile industry | • Computing equipment |

• Medical / dental instruments | • Measuring instruments | • Miscellaneous equipment | • Pharmaceutical industry |

• Orthopedic implants | • Safety equipment | • Petrochemical industry | • Industrial valves |

•Fixing and movable equipment | • Sanitary fittings | • General machinery | • Pumps and general connections |

• Food and beverage processing | • Instrumentation equipment | • Pharmaceutical industry | • Textile equipment |

3, Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

WELCOME TO VISIT OUR FACTORY !

2. We provide a competitive price.

3. High precision, tolerance can be within ±0.005mm.

4. 12 years' export experience.

5. Small order also is welcomed.

6. We provide one-stop service, including mold and assembly.

7. All your information is confidential, and we can sign NDA as well.