Наружный автоматический пластиковый ПВХ шланг трубы

- Категория: Power Pipe Threaders >>>

- Поставщик: Zhangjiagang,Sevenstars,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 14280.60 $* | 14994.95 $* |

| Aug-16-2025 | 14160.86 $* | 14868.92 $* |

| Jul-16-2025 | 11880.85 $* | 12474.61 $* |

| Jun-16-2025 | 13920.57 $* | 14616.8 $* |

| May-16-2025 | 12120.66 $* | 12726.84 $* |

| Apr-16-2025 | 13680.99 $* | 14364.44 $* |

| Mar-16-2025 | 13560.14 $* | 14238.76 $* |

| Feb-16-2025 | 13440.31 $* | 14112.4 $* |

| Jan-16-2025 | 13320.93 $* | 13986.6 $* |

Характеристики

Product Description

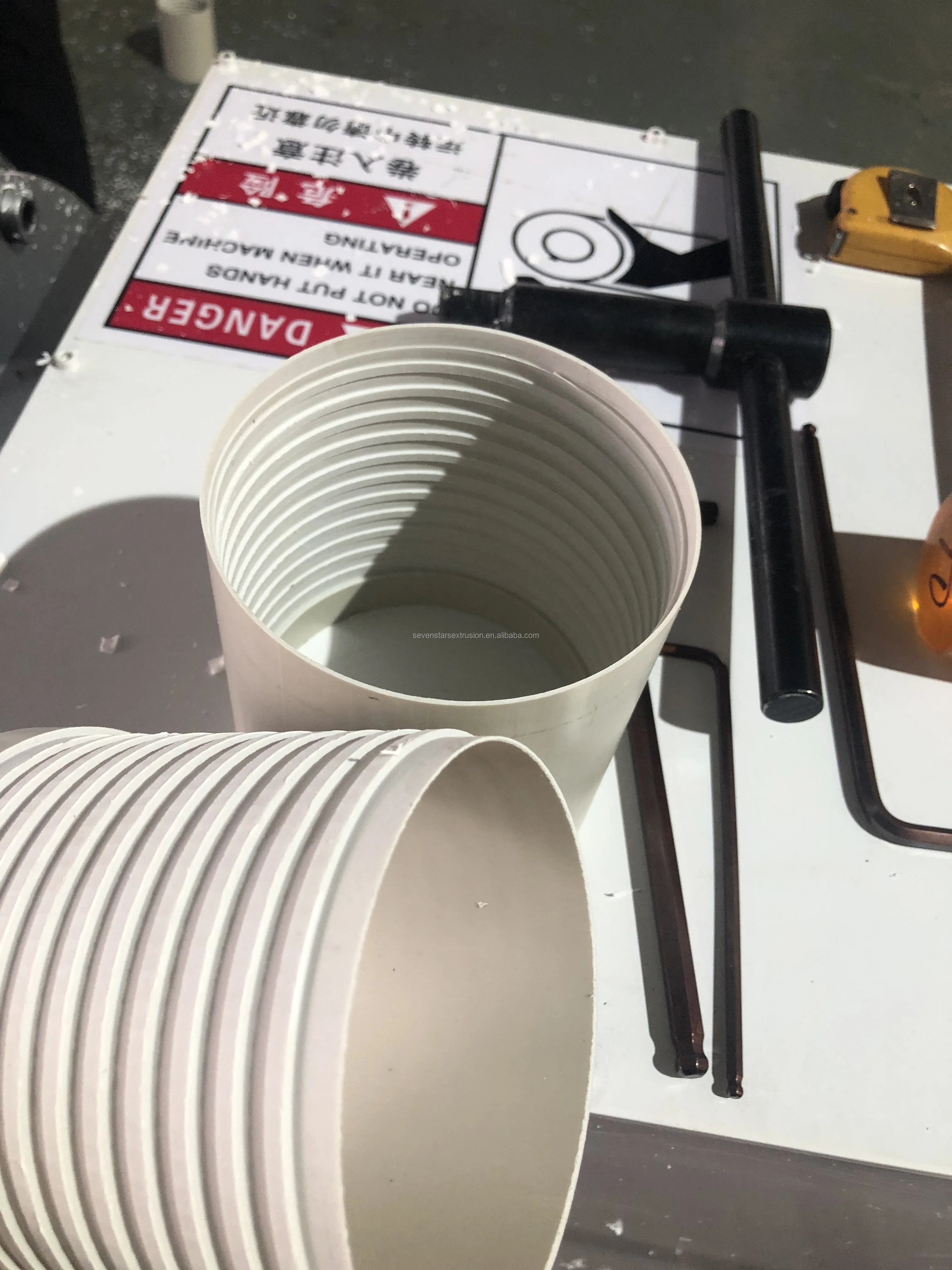

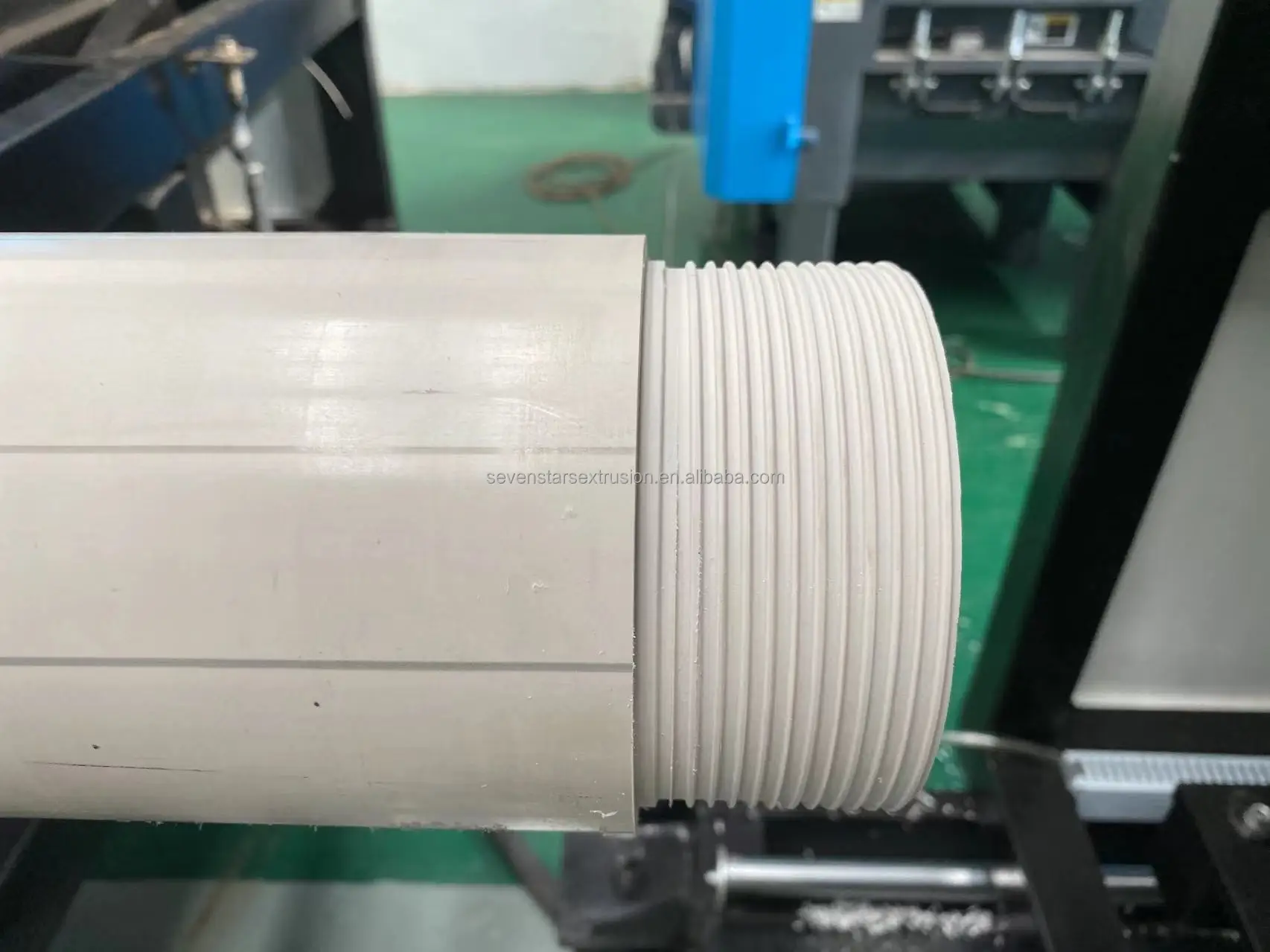

Outer automatic plastic PVC hose pipe threading machine

PVC perforated pipes have a wide range of applications, and can be divided into well wall pipes, water filter pipes, ventilation pipes, rainwater collection pipes, asphalt pipes, etc. according to their uses.

Used in well-drilling engineering; drainage system; ventilation of grain storage and grain piles; rainwater collection and reuse; agricultural irrigation; water plant mud drainage and many other fields.

This pipes are also used in airports, railways, highways, sports fields, parks, roof gardens, retaining walls, basements, tunnels, slope protection and drainage projects.

It can effectively reduce groundwater pressure, remove excess water, protect soil and buildings from damage due to seepage deformation, and protect flowers and trees from waterlogging.

Sevenstars' plastic pipe thread processing machine is specially designed and developed in order to adapt to the current hardware plumbing, chemical and agricultural drainage and irrigation departments used plastic pipe thread processing equipment, is a special plastic pipe thread processing machinery, used for plastic pipe end of the inner hole and outer circle for thread processing and forming connection. The machine is controlled by CNC, it can process the threaded pipe automatically, it only needs to change the preset program to process the pipe with different diameters, convenient and quick.

Using our plastic pipe thread processing machine to process plastic pipe thread forming fast, high efficiency, thread quality is good, can efficiently complete a variety of USES of different tooth type, tooth distance thread processing, such as casing pipe, mine pipe, water pump pipe.

Specification

item | value |

Type | blade cutting machine |

Core Components | CNC, Motor |

Brand Name | SEVENSTARS |

Voltage | 380V 50HZ 3P OR CUSTOMIZED |

Power | 9kw |

Key Selling Points | High-accuracy |

Applicable Industries | Manufacturing Plant, Construction works |

Saw Blade Diameter | 15cm |

Max. Cutting Depth | 2cm |

blades quantity | can be customized,20pcs |

blade diameter | 150mm |

groove distance | 5mm or customized |

suitable pipe diameter | 63-630mm |

Slotting machine

Related product

Contact us

Packing & Delivery

Sea worthy packing

Company Profile

Zhangjiagang Sevenstars Machinery Co., Ltd. is a group company. We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines.

For plastic machines, our main products include:

big-mouth PVC pipe extrusion production lines,

PE big-mouth for gas,

water supply extrusion production lines,

PET bottle recycling line

PE/PP film recycling line

PVC/WPC foam board extrusion line

PVC/WPC profile extrusion line

PP hollow sheet extrusion line

HDPE/LDPE pipe extrusion line

PPR PIPE extrusion line

plastic extruders,

high speed mixers and various plastic auxiliary machines.

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

For plastic machines, our main products include:

big-mouth PVC pipe extrusion production lines,

PE big-mouth for gas,

water supply extrusion production lines,

PET bottle recycling line

PE/PP film recycling line

PVC/WPC foam board extrusion line

PVC/WPC profile extrusion line

PP hollow sheet extrusion line

HDPE/LDPE pipe extrusion line

PPR PIPE extrusion line

plastic extruders,

high speed mixers and various plastic auxiliary machines.

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

FAQ

Why choose us?

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

Похожие товары

Высококачественная электрическая машина для резки труб

US $100.00-$110.00

Электрическая Резьбовая машина

US $200.00-$210.00