Лучшая цена титанового сплава титановая проволока/стержень GR1 GR2 GR5 GR7 оптимальное

- Категория: Titanium Wire >>>

- Поставщик: Guangdong,Lange,Steel,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 32.84 $* | 33.93 $* |

| Jul-16-2025 | 26.61 $* | 27.61 $* |

| Jun-16-2025 | 31.75 $* | 32.51 $* |

| May-16-2025 | 31.97 $* | 32.43 $* |

| Apr-16-2025 | 25.52 $* | 26.77 $* |

| Mar-16-2025 | 31.41 $* | 32.10 $* |

| Feb-16-2025 | 30.34 $* | 31.97 $* |

| Jan-16-2025 | 30.33 $* | 31.65 $* |

Характеристики

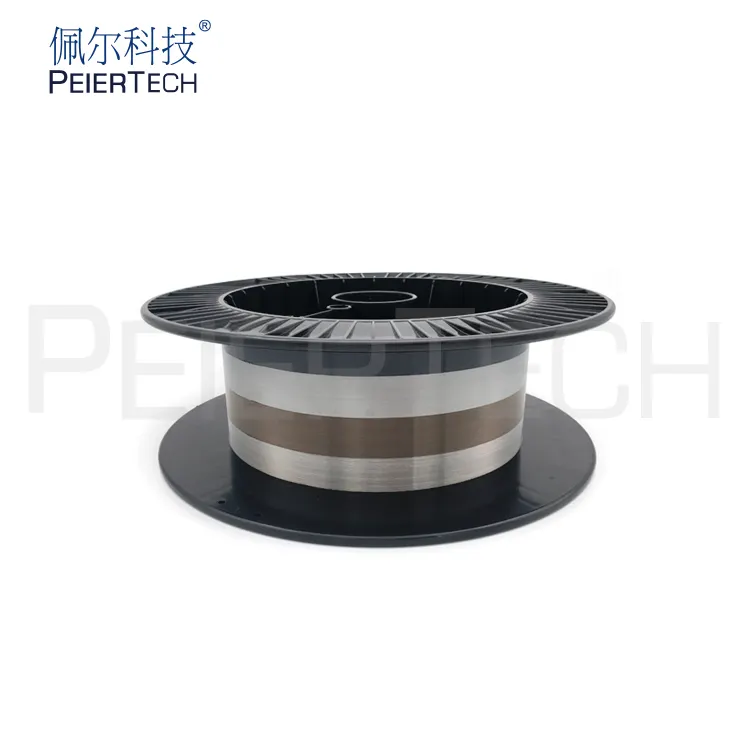

Product photos

Product Description

标题

Performance and purpose of titanium alloys of various materials

Industrial pure titanium TA1, TA2, TA3

Excellent stamping performance. Various forms of welding can be carried out with good welding performance, and the welding joint can reach 90% of the strength of the base metal. Easy to cut with saws and grinding wheels, with good mechanical processing performance. Excellent corrosion resistance

Used for parts below 350 ℃ with low stress and parts stamped into various complex shapes. For example, thermal power plant condenser; Pipeline systems, valves, and pumps corroded by marine seawater; Chemical heat exchangers, pump bodies, distillation towers; Seawater desalination system, platinum plated anode; The skeleton, skin, engine components, crossbeams, etc. of an aircraft.

TA6

It has good welding performance and high creep strength, but the process plasticity is low and can deform under hot conditions. The alloy is not sensitive to cuts when subjected to axial loads, and the cutting performance is still good

Parts and welding parts working below 400 ℃

TA7

Poor stamping performance and good thermoplastic properties. Various forms of welding can be carried out with good performance, and the strength and plasticity of the welded joint can be equal to the base metal. The mechanical processing performance is the same as that of industrial pure titanium. Good corrosion resistance and high temperature thermal stability

Structural components that work for a long time below 500 ℃ can be used for various die forgings

TA8

Good thermoplastic properties. It can be welded in various forms with good weldability. The machinability is the same as that of industrial pure titanium. Good antioxidant properties

Long term working parts below 500 ℃. Capable of manufacturing engine compressor discs and blades

TC1

Good stamping performance. It can be welded in various forms with good weldability. The machinability is the same as that of industrial pure titanium. Good antioxidant properties

Parts for work below 400 ℃. Suitable for various sheet metal, stamping and welding parts

TC2

At 350 ℃, the endurance strength of 100h is more than 400MPa, and hot working has good plasticity. Heated to 350-400 ℃, there is no tendency for embrittlement, so it can be used to weld parts that work at high temperatures

Parts, welding parts, die forgings, and bending parts for work below 500 ℃

TC4

Poor stamping performance and good thermoplastic properties. Various forms of welding can be carried out, and the strength of the welded joint can reach 90% of the strength of the base metal. The mechanical processing performance is still good, requiring the use of hard alloy, large cutting volume, slow speed, and sufficient cooling. Good corrosion resistance and thermal stability. It is one of the most widely used titanium alloys

Parts for long-term operation below 400 ℃

Industrial pure titanium TA1, TA2, TA3

Excellent stamping performance. Various forms of welding can be carried out with good welding performance, and the welding joint can reach 90% of the strength of the base metal. Easy to cut with saws and grinding wheels, with good mechanical processing performance. Excellent corrosion resistance

Used for parts below 350 ℃ with low stress and parts stamped into various complex shapes. For example, thermal power plant condenser; Pipeline systems, valves, and pumps corroded by marine seawater; Chemical heat exchangers, pump bodies, distillation towers; Seawater desalination system, platinum plated anode; The skeleton, skin, engine components, crossbeams, etc. of an aircraft.

TA6

It has good welding performance and high creep strength, but the process plasticity is low and can deform under hot conditions. The alloy is not sensitive to cuts when subjected to axial loads, and the cutting performance is still good

Parts and welding parts working below 400 ℃

TA7

Poor stamping performance and good thermoplastic properties. Various forms of welding can be carried out with good performance, and the strength and plasticity of the welded joint can be equal to the base metal. The mechanical processing performance is the same as that of industrial pure titanium. Good corrosion resistance and high temperature thermal stability

Structural components that work for a long time below 500 ℃ can be used for various die forgings

TA8

Good thermoplastic properties. It can be welded in various forms with good weldability. The machinability is the same as that of industrial pure titanium. Good antioxidant properties

Long term working parts below 500 ℃. Capable of manufacturing engine compressor discs and blades

TC1

Good stamping performance. It can be welded in various forms with good weldability. The machinability is the same as that of industrial pure titanium. Good antioxidant properties

Parts for work below 400 ℃. Suitable for various sheet metal, stamping and welding parts

TC2

At 350 ℃, the endurance strength of 100h is more than 400MPa, and hot working has good plasticity. Heated to 350-400 ℃, there is no tendency for embrittlement, so it can be used to weld parts that work at high temperatures

Parts, welding parts, die forgings, and bending parts for work below 500 ℃

TC4

Poor stamping performance and good thermoplastic properties. Various forms of welding can be carried out, and the strength of the welded joint can reach 90% of the strength of the base metal. The mechanical processing performance is still good, requiring the use of hard alloy, large cutting volume, slow speed, and sufficient cooling. Good corrosion resistance and thermal stability. It is one of the most widely used titanium alloys

Parts for long-term operation below 400 ℃

Product display

About us

Packaging and delivery

FAQ

Frequently asked questions

Q: What kind of job is your company?

A: Our company is a professional manufacturer. We mainly produce nickel alloy products, nickel alloy seamless pipe, plate, rod, wire, belt and other metal products.

Q: What are your strengths?

A: First of all, we have an absolute advantage in the price. Secondly, in the product quality has also carried out strict control. In addition, we will strictly follow the customer's requirements, to provide customers with perfect customized services

Q: How long is your delivery time?

A: The product will be delivered as soon as possible on the basis of quality assurance.

Q: Which payment method can you choose?

A: Wire transfer, letter of credit, D / A, D / P, MoneyGram, Western Union and PayPal.

Q: How can your company maintain a long-term and stable business relationship with your customers?

A: 1. We provide consumers with considerate service and high-quality service. Guarantee the interests of consumers with preferential prices and careful packaging. 2. We have professional customer service personnel to solve all the problems before and after sales. 3. Professional researchers can meet all of your customized requirements.

A: Our company is a professional manufacturer. We mainly produce nickel alloy products, nickel alloy seamless pipe, plate, rod, wire, belt and other metal products.

Q: What are your strengths?

A: First of all, we have an absolute advantage in the price. Secondly, in the product quality has also carried out strict control. In addition, we will strictly follow the customer's requirements, to provide customers with perfect customized services

Q: How long is your delivery time?

A: The product will be delivered as soon as possible on the basis of quality assurance.

Q: Which payment method can you choose?

A: Wire transfer, letter of credit, D / A, D / P, MoneyGram, Western Union and PayPal.

Q: How can your company maintain a long-term and stable business relationship with your customers?

A: 1. We provide consumers with considerate service and high-quality service. Guarantee the interests of consumers with preferential prices and careful packaging. 2. We have professional customer service personnel to solve all the problems before and after sales. 3. Professional researchers can meet all of your customized requirements.

Похожие товары

ASTM F136 GR23 титановая проволока в катушке

US $80.00-$100.00

Ti-6Al-4V Gr5 проволока из титанового сплава для ювелирных изделий

US $52.00-$65.00