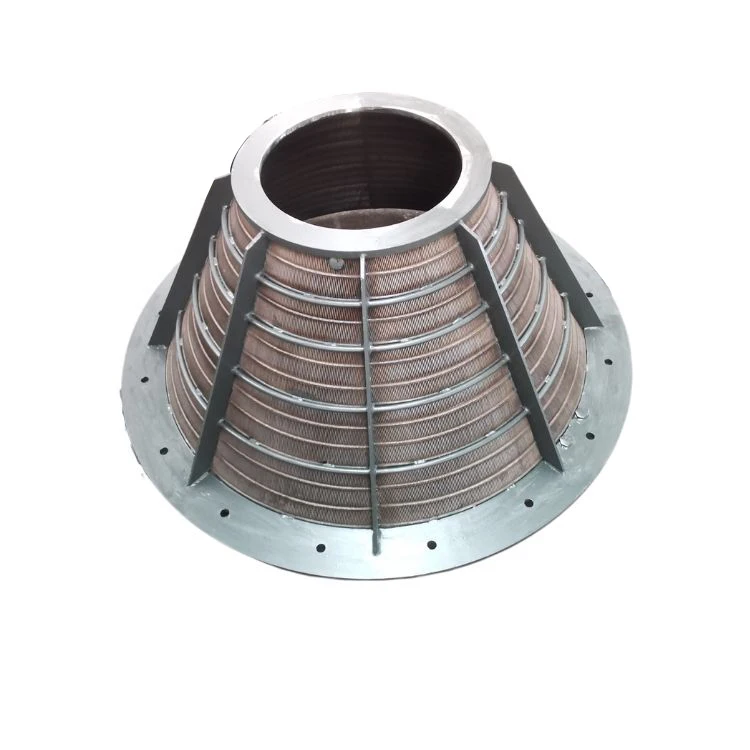

Вертикальная центрифужная корзина из нержавеющей стали Детали угольной шахты инструмент для

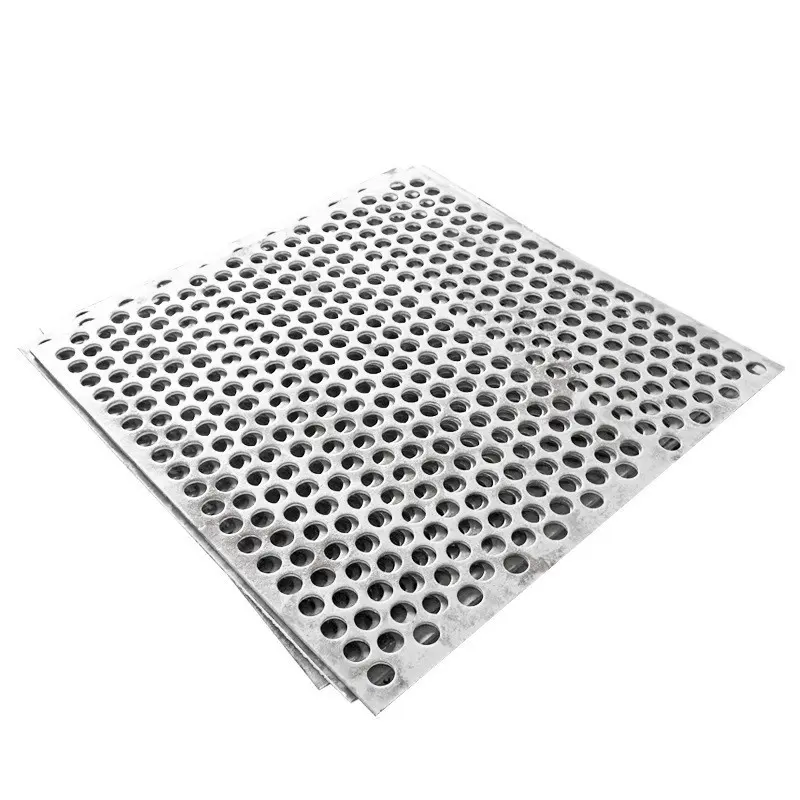

- Категория: Filter Meshes >>>

- Поставщик: Tianjin,Taishouxing,International,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 102.76 $* | 107.97 $* |

| Aug-16-2025 | 101.80 $* | 106.41 $* |

| Jul-16-2025 | 85.28 $* | 89.60 $* |

| Jun-16-2025 | 100.29 $* | 105.5 $* |

| May-16-2025 | 87.74 $* | 91.92 $* |

| Apr-16-2025 | 98.42 $* | 103.71 $* |

| Mar-16-2025 | 97.39 $* | 102.26 $* |

| Feb-16-2025 | 96.80 $* | 101.49 $* |

| Jan-16-2025 | 95.26 $* | 100.1 $* |

Характеристики

Specifications

* Plating:Stainless steel * Type:Machining Parts * Certification:ASTM * Category:Other Replacement Parts

* Plating:Stainless steel * Type:Machining Parts * Certification:ASTM * Category:Other Replacement Parts

Product Overview

Product Details

Item | TSX-99 China Industry WSL Horizontal Vibrating Centrifuge Spin Dryer Coal Machine For Mining |

Applicable Industries | Energy & Mining |

Place of Origin | China |

Production place | Tianjin |

Voltage | 380V\\660V |

Weight | 6.5-11.5tons |

Warranty | 1 Year |

Core Components | Vibrating Motor |

Key Selling Points | Competitive Price |

Material | Q355B |

Certification | ISO9001:2008 |

Diameter of Basket | 1100-1650mm |

Color | White or customization |

MOQ | 1 set |

Capacity | 120-400t/h |

Vibrating Motor | 3.0*2~5.8*2 kw |

Overall Dimension | 2507*2817*1864mm~3208*3135*2231mm |

Drive Motor | 30-75kw |

Delivery Time | 60days |

WSL Horizontal Vibrating Centrifuges Technical Data | ||||||||||||||||||

Model | Capacity(t/h) | Feeding Size (mm) | Surface Moisture(%<) | Diameter of Basket (mm) | Basket Aperture(mm) | Drive Motor(kw) | Vibrating Motor (kw) | Pump Motor (kw) | Overall Dimension A*B*C (mm) | |||||||||

WSL1100 | 120-150 | 0-50 | 6-9 | 1100 | 0.2-1.5 | 30 | 3.0*2 | 0.75 | 2507*2817*1864 | |||||||||

WSL1200 | 150-175 | 0-50 | 6-9 | 1200 | 0.2-1.5 | 37 | 3.0*2 | 0.75 | 2507*2817*1864 | |||||||||

WSL1300 | 180-210 | 0-50 | 6-9 | 1300 | 0.2-1.5 | 37 | 3.0*2 | 0.75 | 2722*2944*2011 | |||||||||

WSL1400 | 210-250 | 0-50 | 6-9 | 1400 | 0.2-1.5 | 45 | 3.0*2 | 0.75 | 2722*2944*2011 | |||||||||

WSL1500 | 300-350 | 0-50 | 6-9 | 1500 | 0.2-1.5 | 55 | 5.8*2 | 0.75 | 3208*3135*2231 | |||||||||

WSL1650 | 350-400 | 0-50 | 6-9 | 1650 | 0.2-1.5 | 75 | 5.8*2 | 0.75 | 3208*3135*2231 | |||||||||

Applications

Factory Display

Company Profile

Packing&Transport

CUSTOMER SATISFACTION

Please don't hesitate to contact us if you have any questions or concerns before or after your purchase. We are committed to your100% satisfaction.

Item Processing Time

The processing time for a specific order varies with the product type and stock status. Mostly, processing

time can be 3 to 15 working days.

Return Policy

If you want to exchange the items received, you must contact us within 3 days of the receipt of your order. And you should pay the additional shipping fees incurred and the items returned should be kept in their original status.

Feedback

Since your feedback is very important to our business`s development, we sincerely invite you to leave positive feedback for us if you are satisfied with our product and service. It`ll just take you 1 minute. Thank you!

time can be 3 to 15 working days.

Return Policy

If you want to exchange the items received, you must contact us within 3 days of the receipt of your order. And you should pay the additional shipping fees incurred and the items returned should be kept in their original status.

Feedback

Since your feedback is very important to our business`s development, we sincerely invite you to leave positive feedback for us if you are satisfied with our product and service. It`ll just take you 1 minute. Thank you!

FAQ

Q: Can I get some screen mesh samples?

A: Yes, sample order is available for quality check and market test. But you jave to pay the sample cost and express cost.

Q: Do you receive customized order?

A: Yes, ODM & OEM are welcomed.

Q: What's the screen mesh lead time.

A: According to the order quantity, small order usually need 7 days, big order need negotiation.

Q: What's your payment terms?

A: We receive L/C, T/T.

Q: Installation

A: At the client’s request, TSX can provide remote guidance installation Technicians to supervise and assist in the assembly and commissioning of the equipment.

Q: What about Warranty? What will we do if the machine is broken down?

A: The warranty period for all of TSX’s structural and mechanical equipment is one year. Wear parts are not covered by warranty unless the component part is found to be flawed.

Q: What should we need to do for if we want to get a best quotation?

A: If you want us recommend a suitable type for you; please let us know as follows:

1).the capacity (tons per hour)

2).output size

3).material type

Q: What could you help me to do for the business?

A: Many thanks for your trust, we can provide you with proposal chart for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipment,flip-flop vibrating screens, circular vibrating screens, sieve bends and centrifuges for classifying, de-sliming, drain & rinsing, and sizing, used in coal washing and preparation plantsand so on .

Q: What are your after sales Service?

A: All equipment manufactured by TSX is of the highest standard and very rarely have our clients experienced any mechanical problems. Should any problems occur, our team of Engineers and Technicians will respond within12 hours of notice by the client.

Q: Delivery time

A: Standard delivery time for vibrating screen is 60 days from receipt of deposit.

A: Yes, sample order is available for quality check and market test. But you jave to pay the sample cost and express cost.

Q: Do you receive customized order?

A: Yes, ODM & OEM are welcomed.

Q: What's the screen mesh lead time.

A: According to the order quantity, small order usually need 7 days, big order need negotiation.

Q: What's your payment terms?

A: We receive L/C, T/T.

Q: Installation

A: At the client’s request, TSX can provide remote guidance installation Technicians to supervise and assist in the assembly and commissioning of the equipment.

Q: What about Warranty? What will we do if the machine is broken down?

A: The warranty period for all of TSX’s structural and mechanical equipment is one year. Wear parts are not covered by warranty unless the component part is found to be flawed.

Q: What should we need to do for if we want to get a best quotation?

A: If you want us recommend a suitable type for you; please let us know as follows:

1).the capacity (tons per hour)

2).output size

3).material type

Q: What could you help me to do for the business?

A: Many thanks for your trust, we can provide you with proposal chart for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipment,flip-flop vibrating screens, circular vibrating screens, sieve bends and centrifuges for classifying, de-sliming, drain & rinsing, and sizing, used in coal washing and preparation plantsand so on .

Q: What are your after sales Service?

A: All equipment manufactured by TSX is of the highest standard and very rarely have our clients experienced any mechanical problems. Should any problems occur, our team of Engineers and Technicians will respond within12 hours of notice by the client.

Q: Delivery time

A: Standard delivery time for vibrating screen is 60 days from receipt of deposit.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Похожие товары

Фильтр для удаления пыли с экрана PTR Platesetter 8600 4300 CTP

US $250.00-$300.00

WOJUN лопасти из медной проволочной сетки с сеткой

US $25.00-$59.00