Бумага из керамического волокна толщиной 1 мм 5 13 1260 термостойкая изоляция силикатного алюминия рулон с

- Категория: Ceramic Fiber Paper >>>

- Поставщик: Zhengzhou,Rongsheng,Import,And,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.27 $* | 0.93 $* |

| Aug-18-2025 | 0.80 $* | 0.53 $* |

| Jul-18-2025 | 0.88 $* | 0.86 $* |

| Jun-18-2025 | 0.2 $* | 0.64 $* |

| May-18-2025 | 0.37 $* | 0.86 $* |

| Apr-18-2025 | 0.18 $* | 0.94 $* |

| Mar-18-2025 | 0.55 $* | 0.25 $* |

| Feb-18-2025 | 0.28 $* | 0.95 $* |

| Jan-18-2025 | 0.92 $* | 0.30 $* |

Характеристики

Products Description

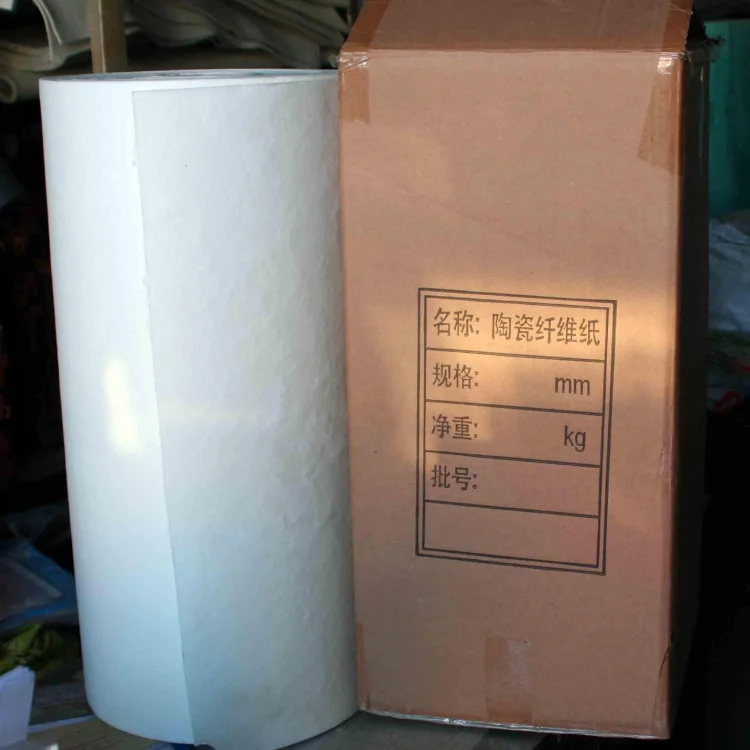

Description of Ceramic Fiber Paper

ceramic fiber paper is manufactured from high-grade ceramic fiber with low slag ball content,It is featured with high temperature resistance and heat insulation and high anti-melt capability,very low thermal conductivity, chemical corrosion resistance and thermal shock stability. ceramic fiber paper with excellent strength, toughness and wind corrision resistance property.ceramic fiber products is an ideal energy saving material for furnaces, kilns, piplines and other thermal equipments.

Features of Ceramic Fiber Paper:

1:Low thermal capacity

2:Low thermal conductivity

3: Excellent electrical insulation properties

4:Excellent machining performance

5: High strength, tear resistance

6: High flexibility

7:Low slag content

8:Excellent fire proof property

1:Low thermal capacity

2:Low thermal conductivity

3: Excellent electrical insulation properties

4:Excellent machining performance

5: High strength, tear resistance

6: High flexibility

7:Low slag content

8:Excellent fire proof property

Specification

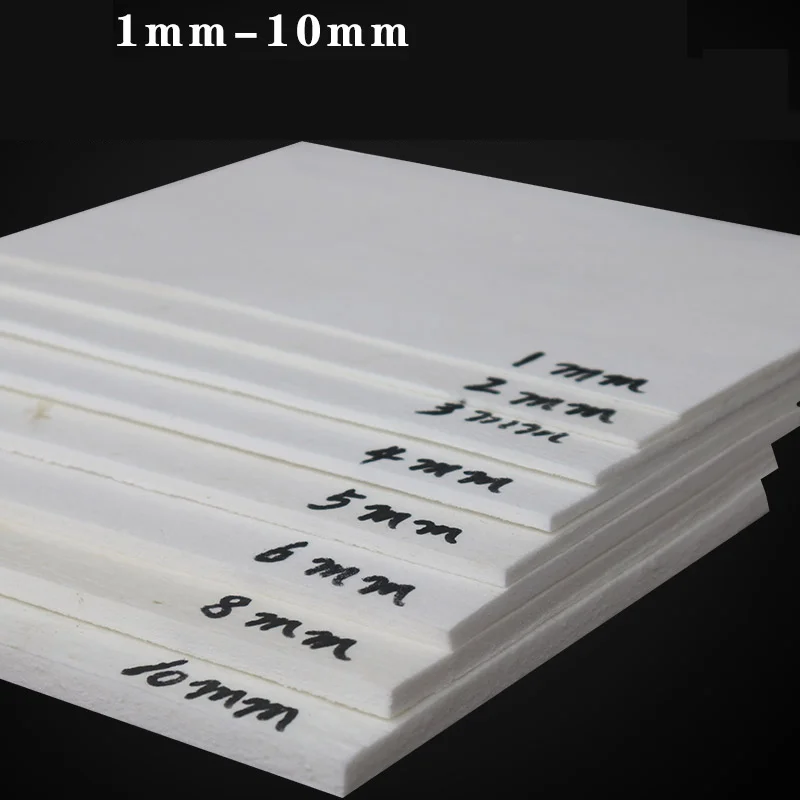

Standard size:60000x610x1mm / 30000x610x2mm / 20000x610x3mm / 15000x610x4mm / 12000x610x5mm / 10000x610x6mm

Type | Standard ceramic fiber paper | High pure ceramic fiber paper | High Aluminium ceramic fiber paper | Zirconium ceramic fiber paper | |||||

Chemical analysis (%) | AL2O3 | 43 | 47 | 55 | 38 | ||||

SiO2 | 53 | 51 | 44 | 44 | |||||

Fe2O3+Ti2O3 | ≤1.2 | ≤0.3 | ≤0.3 | ≤0.2 | |||||

CaO+MgO | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.2 | |||||

NaO+K2O | ≤0.5 | ≤0.3 | ≤0.3 | ≤0.2 | |||||

Crganic Content (%) | 5% | ≤5% | ≤5% | ≤5% | |||||

Density(kg/m3) | 180-220 | 180-220 | 180-220 | 180-220 | |||||

Work Temperature | 1050 | 1150 | 1250 | 1350 | |||||

Thickness | 0.5-12mm | ||||||||

size (mm) | 40000x1220x1;40000x610x1; 30000x1220x2; 30000x610x2;20000x1220x3;20000x610x3;15000x610x4; 10000x610x5 | ||||||||

Product Application

1:Industrial insulation, sealing, anti-corrosion material

2:Insulation material for instruments and heating element

3:Insulation material for automobile and aerospace industry

4:Expansion joints filling material

5:Isolation for construction material, metallurgy and glass industries,

6:Molten metal sealing gasket

7:Fireproof material

8:Substitute for glass fiber and asbestos fiber

2:Insulation material for instruments and heating element

3:Insulation material for automobile and aerospace industry

4:Expansion joints filling material

5:Isolation for construction material, metallurgy and glass industries,

6:Molten metal sealing gasket

7:Fireproof material

8:Substitute for glass fiber and asbestos fiber

Production Process

Why Choose Us

RS Refractories Co., Ltd. introduction

RS Refractories Co., Ltd. is located in Henan, China. Our company has professional scientific and technical personnel and production team, and we have our own fully automated factories. For more than ten years, we have focused on the development and innovation of refractory materials and high-temperature furnace technology, and strive to provide customers with comprehensive, personalized and cost-effective services with high-quality products. Our products are widely used in electric power, metallurgy, petrochemical and other fields, and are exported to more than 70 countries and regions in the world such as Europe, America, Oceania, Southeast Asia, and the Middle East.

RS Refractories Co., Ltd. is a first-class supplier of refractory materials, we can provide you with the most advantageous quotations and products. Looking forward to be your partner!

Customer visit

FAQ

Q1.Are you Manufacturer?

A:Yes, of course, our factory is in Xinmi,zhengzhou city,Henan province.

Q2.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q3.Do you accept OEM?

A:Yes, we can do OEM.

Q4.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q5.What are the payment terms?

A:Usually T/T,but L/C,Western Union etc are available for us.

Q6.How long is delivery time?

A:The delivery time usually depends on the order quantity, usually around 7-12 days.

Q7.How are your products' quality?

A:The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q8.How to solve the quality problems?

A:Yes, of course, our factory is in Xinmi,zhengzhou city,Henan province.

Q2.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q3.Do you accept OEM?

A:Yes, we can do OEM.

Q4.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q5.What are the payment terms?

A:Usually T/T,but L/C,Western Union etc are available for us.

Q6.How long is delivery time?

A:The delivery time usually depends on the order quantity, usually around 7-12 days.

Q7.How are your products' quality?

A:The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q8.How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our company will be responsible to make compensation for it.

Q9.What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q10.How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q9.What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q10.How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Похожие товары

Нераскаленные автомобильные коврики

US $2.50

Теплоотражающая термоизоляционная бумага из керамического волокна

US $52.00-$60.00