Shenzhen cavo laser 1 кВт/1500 Вт/2000 Вт/3000 Вт лазерный сварщик волоконно-лазерный сварочный аппарат для точечной сварки литий-ионного

- Категория: Laser Welders >>>

- Поставщик: Shenzhen,Jiahe,Laser,Intelligent,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 5355.19 $* | 5623.8 $* |

| Aug-16-2025 | 5310.4 $* | 5576.16 $* |

| Jul-16-2025 | 4455.4 $* | 4678.25 $* |

| Jun-16-2025 | 5220.84 $* | 5481.77 $* |

| May-16-2025 | 4545.94 $* | 4772.46 $* |

| Apr-16-2025 | 5130.67 $* | 5387.17 $* |

| Mar-16-2025 | 5085.93 $* | 5339.55 $* |

| Feb-16-2025 | 5040.57 $* | 5292.59 $* |

| Jan-16-2025 | 4995.77 $* | 5245.30 $* |

Характеристики

Product Description

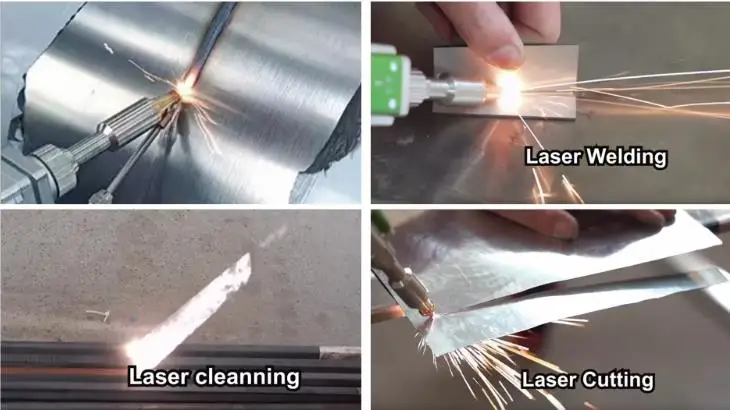

OPERATION PROCESS

1. Assembling Wire Feeder

Assembling wires in the feeder and then fix it onto the welding head.

2. Turning on Protection Gas

Set on the system board, and then turn on the gas, make the gas pressure value at 10-15.

3. System setting and focus fixing

Setting the system for different type of job and materials. Multi language optional

4. Working!!!

3 modes optional, Laser welding, Laser cutting and Laser Cleanning

5. Replacing glasses

Easy taking out and replacing. Please ensure the glasses are perfectly clean before replacing.

Specification

Laser Power | 1000W, 1500W, 2000W.3000W |

Laser Source | Raycus/Max/IPG |

Fiber Wire Length | 5/10 Meters |

Laser Wavelength | 1070nm |

Laser Head | Chaoqiang |

Operate Mode | Continuation/Modulate |

Spot Adjusting Range | 0.1-3mm |

Repeating Precision | ±0.01mm |

Cabinet Size | 486*807*980mm |

Machine Weight | About 140KG~175KG |

Voltage | 110V/220V Optional |

Water Chiller | Hanli |

Welding parameters of fiber laser hand-held welding machine | ||||||||

stock thickness | service power | depth weld | welding manner | |||||

1 | stainless steel 0.5mm | 400W | 0.5mm | seamless pipe | ||||

2 | stainless steel 1.0mm | 600W | 1.0mm | |||||

3 | stainless steel 1.5mm | 750W | 1.5mm | |||||

4 | stainless steel 2.0mm | 950W | 2.0mm | |||||

5 | stainless steel 2.5mm | 1150W | 2.5mm | |||||

6 | stainless steel 3.0mm | 1400W | 3.0mm | |||||

7 | stainless steel 3.5mm | 1550W | 3.5mm | |||||

8 | stainless steel 4.0mm | 1700W | 4.0mm | |||||

9 | stainless steel 4.5mm | 1850W | 4.5mm | |||||

10 | stainless steel 5.0mm | 2000W | 5.0mm | |||||

stock thickness | service power | depth weld | welding manner | |||||

1 | aluminium 0.8mm | 600W | 0.8mm | |||||

2 | aluminium 1.0mm | 750W | 1.0mm | |||||

3 | aluminium 1.5mm | 950W | 1.5mm | |||||

4 | aluminium 2.0mm | 1200W | 2.0mm | |||||

5 | aluminium 2.5mm | 1350W | 2.5mm | |||||

6 | aluminium 3.0mm | 1700W | 3.0mm | |||||

7 | aluminium 3.5mm | 2000W | 3.5mm | |||||

Remark | Stainless steel, 1. Welding mirror stainless steel needs to increase part of the power (low carbon steel, iron plate, can refer to the above parameters). | |||||||

2. It is easy to splash when galvanized sheet is welded and damage the protective lens seriously. It is recommended that automatic welding be performed. | ||||||||

3. Gap less than 0.1mm can be directly welded, less than 0.3mm need to add swing function (thin material is not conducive to splicing welding, gap should be less than one tenth of the material). | ||||||||

4. Wire welding gap should not be greater than 0.6mm, (thin plate can not be wire splicing welding, easy to weld through) | ||||||||

Aluminum material, 1. Because there are many series of aluminum alloy, the welding effect is also different, you can refer to the welding parameters of pure aluminum. | ||||||||

2. Gap less than 0.1mm can be directly welded, less than 0.3mm need to add swing function (thin aluminum is not conducive to splicing welding, gap need to be less than one tenth of the material). | ||||||||

3. Wire welding gap should not be greater than 0.6mm, (thin plate can not be wire splicing welding, easy to weld through). | ||||||||

4. The higher the swing frequency (speed), the shallower the melting depth, the larger the swing diameter, the weaker the laser energy, so the laser power needs to be adjusted during welding. | ||||||||

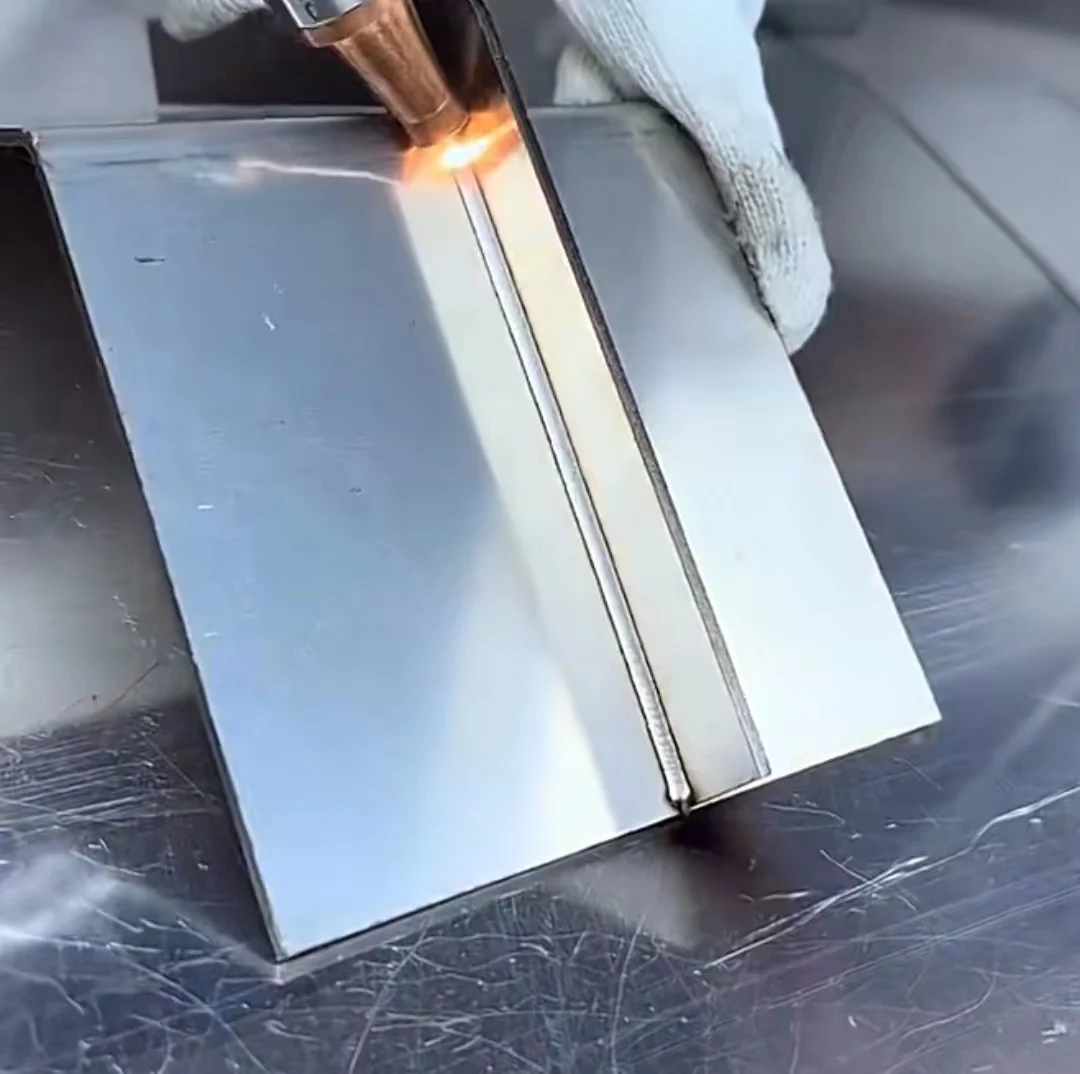

Samples Display

Company Profile

Company Profile

Shenzhen Jiahe Laser Inteligent Technology Co, Ltd. is located in Shenzhen city, Guangdong, China. It is a laser equipment high-tech enterprise that integrates R&D, manufacturing, sales and service. It is dedicated to laser process R&D, laser equipment design R&D, production, technical support, service and consulting.

Our company's main products include: laser cutting machine, laser welding machine, laser marking machine, industry-specific and automated laser equipment, etc, applied to electronics, IC chips, electrical appliances, lighting fixtures, jewelry, hardware tools, sanitary ware, instruments Instrumentation, automobile and motorcycle accessories, mobile phone communications components, molds, precision machinery, medical equipment, IT digital, metal housing, military aviation components, garment leather, craft gifts, advertising decoration, models, cookware, kitchen utensils and other industries.

Jiahe laser product quality are stable and reliable, with a professional R & D team, while pursuing excellent quality, Jiahe laser also provides customers with timely, comfortable pre-sale, sales, after-sales service and excellent cost-effective products. Jiahe Laser has won the trust and praise of customers by implementing the business philosophy of "helping customers succeed, creating value models, and building industrial laser equipment industry to serve high-end brands". Customers are located throughout the country and overseas. In 2021, sold more than 5,000 laser equipment.

Our company has established a complete production and sales and after-sales service system, has production bases in Shenzhen, Wenzhou,Kunshan and Xiamen, has a large-scale laser cutting machine production base in Dongguan, and has offices in major domestic industrial cities and regions. There are equipment demonstrations, process proofing, sales and after-sales services, and resident technical service personnel, to provide customers with timely, comfortable pre-sales, sales, after-sales support and services.

Shenzhen Jiahe Laser Inteligent Technology Co, Ltd. is located in Shenzhen city, Guangdong, China. It is a laser equipment high-tech enterprise that integrates R&D, manufacturing, sales and service. It is dedicated to laser process R&D, laser equipment design R&D, production, technical support, service and consulting.

Our company's main products include: laser cutting machine, laser welding machine, laser marking machine, industry-specific and automated laser equipment, etc, applied to electronics, IC chips, electrical appliances, lighting fixtures, jewelry, hardware tools, sanitary ware, instruments Instrumentation, automobile and motorcycle accessories, mobile phone communications components, molds, precision machinery, medical equipment, IT digital, metal housing, military aviation components, garment leather, craft gifts, advertising decoration, models, cookware, kitchen utensils and other industries.

Jiahe laser product quality are stable and reliable, with a professional R & D team, while pursuing excellent quality, Jiahe laser also provides customers with timely, comfortable pre-sale, sales, after-sales service and excellent cost-effective products. Jiahe Laser has won the trust and praise of customers by implementing the business philosophy of "helping customers succeed, creating value models, and building industrial laser equipment industry to serve high-end brands". Customers are located throughout the country and overseas. In 2021, sold more than 5,000 laser equipment.

Our company has established a complete production and sales and after-sales service system, has production bases in Shenzhen, Wenzhou,Kunshan and Xiamen, has a large-scale laser cutting machine production base in Dongguan, and has offices in major domestic industrial cities and regions. There are equipment demonstrations, process proofing, sales and after-sales services, and resident technical service personnel, to provide customers with timely, comfortable pre-sales, sales, after-sales support and services.

Certifications

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Safe Package

Plastic all over cover, wood carton boxes, stable and safe

Why Choose Us

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

contact me

Shenzhen Jiahe Laser Intelligent Technology Co., Ltd

Louis Liu

Skype:live:.cid.f437bd7896882ecd

Wechat/Whatsapp:19154951839

E-mail: lyt654825111@163.com

Tel:19154951839

Louis Liu

Skype:live:.cid.f437bd7896882ecd

Wechat/Whatsapp:19154951839

E-mail: lyt654825111@163.com

Tel:19154951839