Машина для укладки

- Категория: Glove Making Machines >>>

- Поставщик: Zhangjiagang,Yicheng,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 13090.76 $* | 13745.21 $* |

| Aug-16-2025 | 12980.56 $* | 13629.6 $* |

| Jul-16-2025 | 10890.11 $* | 11435.97 $* |

| Jun-16-2025 | 12760.22 $* | 13398.17 $* |

| May-16-2025 | 11110.61 $* | 11666.84 $* |

| Apr-16-2025 | 12540.0 $* | 13167.48 $* |

| Mar-16-2025 | 12430.68 $* | 13052.50 $* |

| Feb-16-2025 | 12320.53 $* | 12936.45 $* |

| Jan-16-2025 | 12210.11 $* | 12821.68 $* |

Характеристики

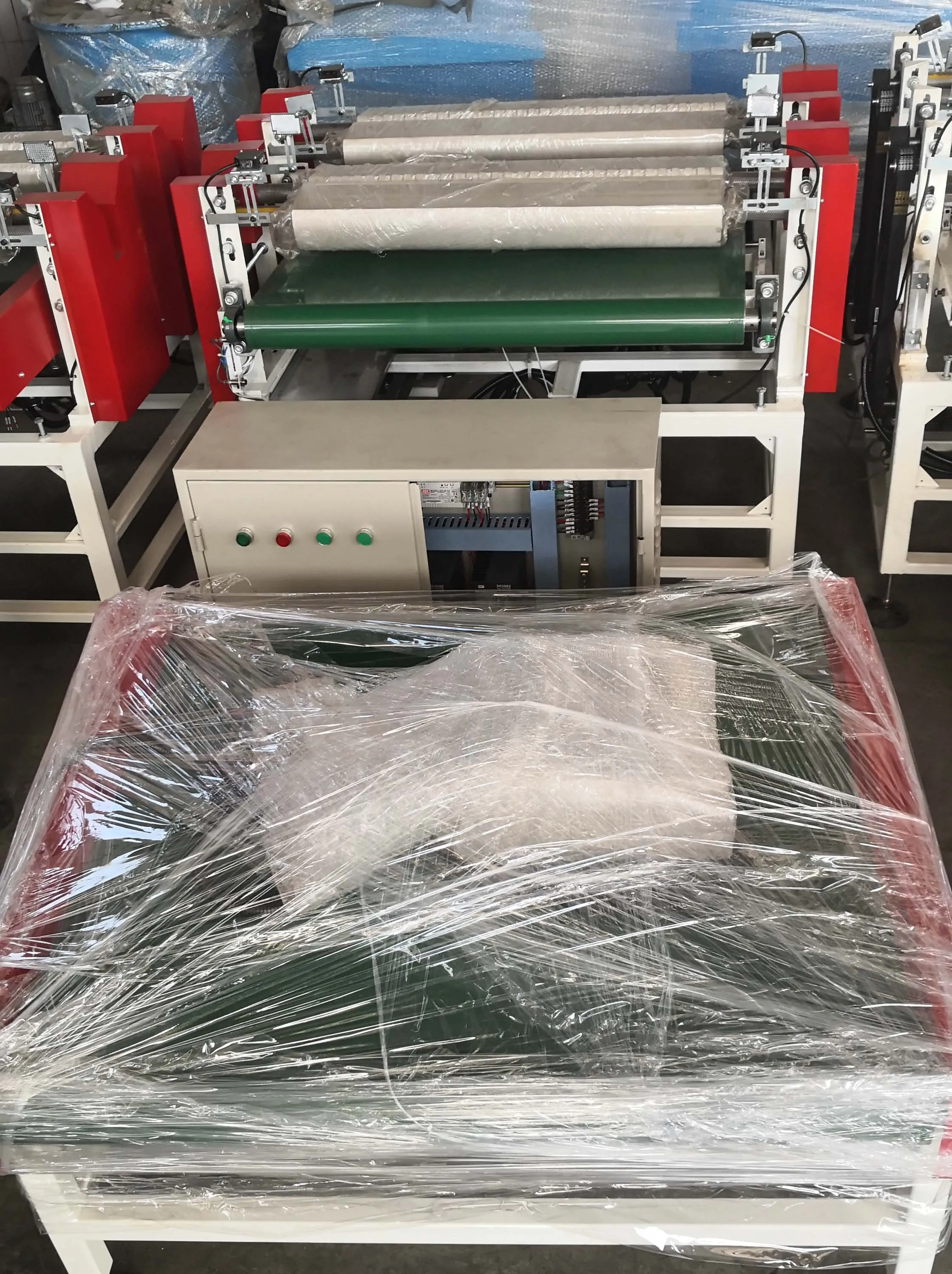

Glove Stacking Machine for Nitrile Gloves

We have Chinese patent for invention for this glove stripping machine, patent no.: 20110244762.2

Description

This equipment has two operation modes: PLC automatic control and manual control. Our counting & stacking has the features of compact size, easy operation, high efficiency, little energy consumption, low maintenance cost. The rollers are adopted to take off the gloves, and cause no damage to gloves. No air source is needed, and the noise is <40dB, high safety and environmental friendly.

As this machine has realized full automatic counting, labor cost can be reduced, and by using this machine, every production line can reduce 2-3 workers, and this greatly help improve working efficiency and lower production cost, so this is the perfect choice of glove manufacturers.

Advantages

- Full-auto running, save 2-3 manpower each line for glove producers

- Easy installation, and no operator needed

- Good order for glove stacking

- Little energy consumption

- No damage to gloves

- Low production cost

- Little maintenance needed

Equipment components

- Platform for machine rack

- Taking-off mechanism

- Conveying mechanism

- Lifting mechanism

- Control system

Technical specifications

1. Platform for rack

- Machine main rack is made of: 50*50 Q235A square tube and 50*25 Q235A

- Machine supporting rack is made of: 40*40 Q235A square tube

- Metal plate protection cover is installed outside the rack

2. Taking-off mechanism

- Composed of 4 pcs of φ150mm*1005 (diameter*length) semicircle rollers

- Made of aluminium alloy, and coated by rubber. No rust and no contaminations to gloves

- 2 of the 4 rollers has grooves and this helps take off the glove more effectively and easy to eliminate the air inside the gloves

- Driven by servo motor with gears and synchronous belt, the semicircle rollers take off the gloves to main conveyor belt

3. Conveying mechanism

- Main conveying system is composed of main conveyor belt, main conveyor aluminum roller, servo motor, chain wheel and etc

- Supporting conveying system is composed of supporting conveyor belt, supporting conveyor aluminum roller, stepping motor and chain wheel

- Gloves which are taken off will be conveyed from main conveyor to supporting conveyo

4. Lifting mechanism

- Composed of lifting screw rod, stepping motor and lifting platform

- Lifting system controls the movements of main conveying system, so that gloves that have been taken off could be stacked neatly on the main conveyor

5. Control system

- Electric cabinet, and main components are SIEMENSbrand

- PLC (SIEMENS) control with touch screen

- Realize full automatic control of the whole equipment, and complete working data are displayed and can be set on the touch panel

Specifications

No | Item | Details |

1 | Motor power (KW) | 3 |

2 | Speed (pcs/min) | 180-280 (adjustable according to production line speed) |

3 | Glove counting setting | 25/50/100 pcs per stack |

4 | Number of stacks | 5 |

5 | Glove length workable range | 230 - 310mm |

6 | Floor space (mm) | 2,500 * 1,800 |

Company profile

Welcome to Yicheng!

Yicheng Machinery is located in Zhangjiagang City, which is around 2 hours drive from Shanghai Pudong International Airport. We are a leading supplier of PVC/latex/nitrile glove production line, with more than 10 years experience in this field.

We have successfully built over 50 turnkey projects all over the world, which make us one of the biggest manufacturers and the most powerful factories for vacuum impregnation machinery.

We have already sold our machines to over 25 countries, like Russia, USA, Saudi, Egypt, Malaysia, Brazil, Guatemala, Vietnam, Kazakhstan, Uzbekistan, Chile, and etc.

We sincerely hope to establish trustworthy and long-term relationships with clients all over the world to develop and move forward hand in hand together!