Автоматическая линейная укупорочная машина для бутылок из ПЭТ-пластика с конвейером жидкого мыльного крема

- Категория: Cosmetics Production Equipment >>>

- Поставщик: Esko,Machinery,Co.,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 5355.87 $* | 5623.36 $* |

| Aug-16-2025 | 5310.8 $* | 5576.99 $* |

| Jul-16-2025 | 4455.29 $* | 4678.93 $* |

| Jun-16-2025 | 5220.6 $* | 5481.16 $* |

| May-16-2025 | 4545.5 $* | 4772.91 $* |

| Apr-16-2025 | 5130.37 $* | 5387.65 $* |

| Mar-16-2025 | 5085.13 $* | 5339.55 $* |

| Feb-16-2025 | 5040.68 $* | 5292.80 $* |

| Jan-16-2025 | 4995.52 $* | 5245.13 $* |

Характеристики

Products Description

Filling Nozzle | 1 Nozzle | 2 Nozzle | 4 Nozzle | 6 Nozzle | 8 Nozzle | 10 Nozzle | 12 Nozzle | ||||||

Filling Speed | 10-25/min | 15-30/min | 25-35/min | 35-45/min | 50-60/min | 60-70/min | 70-80/min | ||||||

Filling Volume | 5-150ml / 10-250ml / 30-500ml / 50-1000ml / 250-2500ml / 300-3000ml / 500-5000ml | ||||||||||||

Main Parts | Siemens PLC, Panasonic Servo Motor, Schneider Electronic, Festo/AirTAC pneumatic component, etc. | ||||||||||||

Remark | The filling design/speed is customized according to client's product and requirement, click here to send us your requirement :) | ||||||||||||

Application Product

Details Images

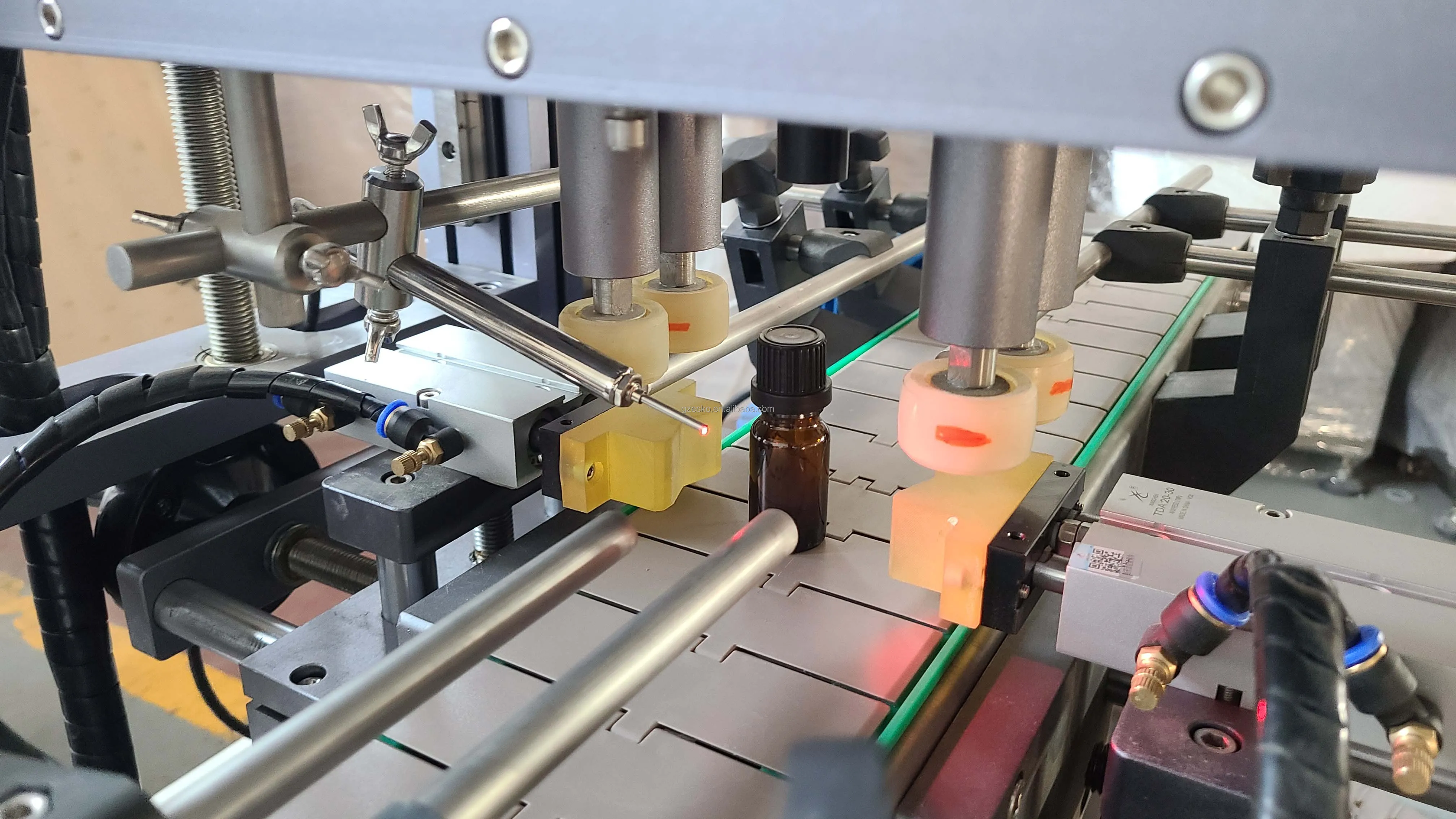

Automatic Cap Loader + Automatic Capping Machine

Can be adopted with different kind of cap loader for your packaging, such as flip-top cap, pump, sprayer, regular threaded cap, etc.

And multiple choices of capping design for different packaging and speed requirement.

And multiple choices of capping design for different packaging and speed requirement.

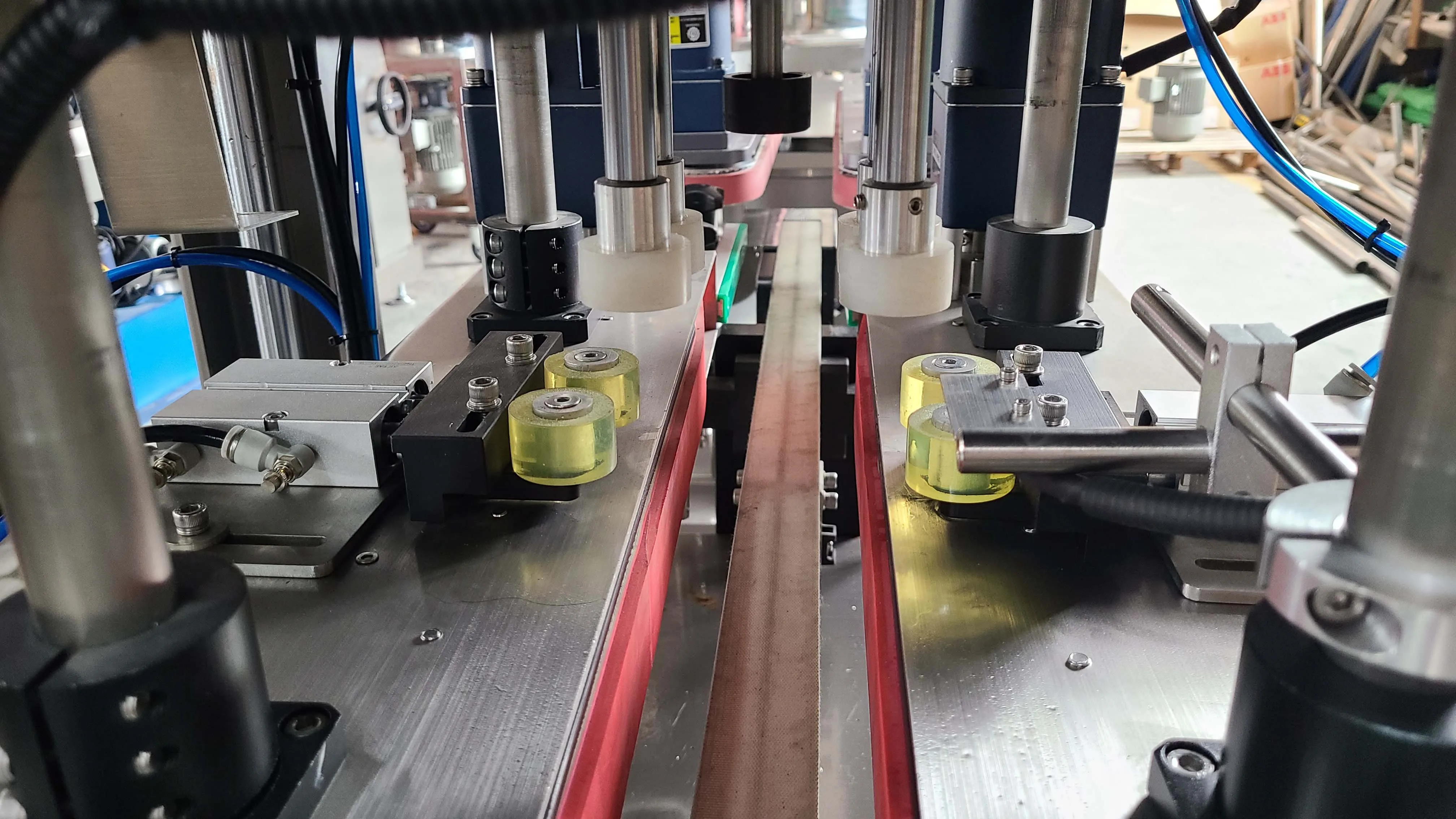

4 Head Belt Type Capping Machine

Generally using for regular sizes bottle or jar, speed 30-50pcs/min.

8 Head High Speed Capping Machine

Designed for high productivity demand, speed can reach to 60-100pcs/min.

4 Head Cylinder Capping Machine

Designed for small packages, such as 5ml vial or jar.

Threaded Cap / Flip Top Cap Loader

Automatic cap loading system for Threaded Cap / Flip Top Cap Loader.

Pump / Sprayer Cap Loader

Automatic cap loading system, with a mechanical gripper to feed Pump / Sprayer Cap automatically.

Festo & AirTAC Cylinder

Adopted with Festo and AirTAC air cylinder, longer service life and working more stable.

All material contact parts are made of SUS316L, the best option for manufacturing cosmetic, food and pharmaceutical products.

Siemens PLC Touch Screen Smart Control

The filling speed and volume of each nozzle can be adjusted on the screen independently. For filling different products we can save the parameter in the screen as recipe, and one-button start when changing different packaging or products.

Complete Production Line

Recommend Products

Buyer's Comment

Purchse & Production Process

Main Component

Project Reference

FAQ

Q: Are you a manufacturer / factory?

A: Yes we are a manufacturer with more than 15 years manufacturing experience in machinery.

Q: I am planning to set up a factory, but i am a green hand, could you help me with that?

A: Sure! We've been helping dozens of client to set up their new factory, generally will offer you a suitable design based on your actual situation, such as your daily production, raw material formula, factory layout, etc. What's more, we can help you to find reliable raw material and packaging supplier in China. After you received our machines, we could send our technician to your factory for installation and training your people.

Q: How long is your warranty? After warranty, what do we do if the machine breaks down?

A: Our warranty is two years, and lifelong maintenance is provided. After warranty we could still offer you online or on-site service.

Q: How do you control or test the quality before shipment?

A: Firstly, our accessories/parts supplier will test their products before they ship to us. After the machines are finished, our Quality Inspectors and Technical Team will test and run each machine, and make a testing video for our client. We'd also like to invite you come to our factory to verify machines yourself.

Q: Are the machines difficult to operate? How can we learn it?

A: Our machines are adopted with PLC smart screen control, very easy to operate. Also, we will make an operation instruction video and send it to our client before shipment, and send our technician to client's factory for trainning if needed. Moreover, we have 24 hours online service, we could have video call with you anytime to answer your questions or providing you operation guidance.

Q: Could i visit your factory to observe machine running?

A: Yes, customers are warmly welcome to visit our factory.

Q: Could you make the machine according to buyer's requirement?

A: Yes, OEM is acceptable. Most of our machines are customized according to customer's need.

A: Yes we are a manufacturer with more than 15 years manufacturing experience in machinery.

Q: I am planning to set up a factory, but i am a green hand, could you help me with that?

A: Sure! We've been helping dozens of client to set up their new factory, generally will offer you a suitable design based on your actual situation, such as your daily production, raw material formula, factory layout, etc. What's more, we can help you to find reliable raw material and packaging supplier in China. After you received our machines, we could send our technician to your factory for installation and training your people.

Q: How long is your warranty? After warranty, what do we do if the machine breaks down?

A: Our warranty is two years, and lifelong maintenance is provided. After warranty we could still offer you online or on-site service.

Q: How do you control or test the quality before shipment?

A: Firstly, our accessories/parts supplier will test their products before they ship to us. After the machines are finished, our Quality Inspectors and Technical Team will test and run each machine, and make a testing video for our client. We'd also like to invite you come to our factory to verify machines yourself.

Q: Are the machines difficult to operate? How can we learn it?

A: Our machines are adopted with PLC smart screen control, very easy to operate. Also, we will make an operation instruction video and send it to our client before shipment, and send our technician to client's factory for trainning if needed. Moreover, we have 24 hours online service, we could have video call with you anytime to answer your questions or providing you operation guidance.

Q: Could i visit your factory to observe machine running?

A: Yes, customers are warmly welcome to visit our factory.

Q: Could you make the machine according to buyer's requirement?

A: Yes, OEM is acceptable. Most of our machines are customized according to customer's need.