Гомогенизатор для косметических кремов мазь вакуумный эмульгирующий миксер

- Категория: Cosmetics Production Equipment >>>

- Поставщик: Wenzhou,Tuoyi,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 13090.59 $* | 13745.64 $* |

| Aug-16-2025 | 12980.23 $* | 13629.73 $* |

| Jul-16-2025 | 10890.95 $* | 11435.8 $* |

| Jun-16-2025 | 12760.95 $* | 13398.41 $* |

| May-16-2025 | 11110.97 $* | 11666.13 $* |

| Apr-16-2025 | 12540.14 $* | 13167.91 $* |

| Mar-16-2025 | 12430.44 $* | 13052.74 $* |

| Feb-16-2025 | 12320.65 $* | 12936.83 $* |

| Jan-16-2025 | 12210.86 $* | 12821.78 $* |

Характеристики

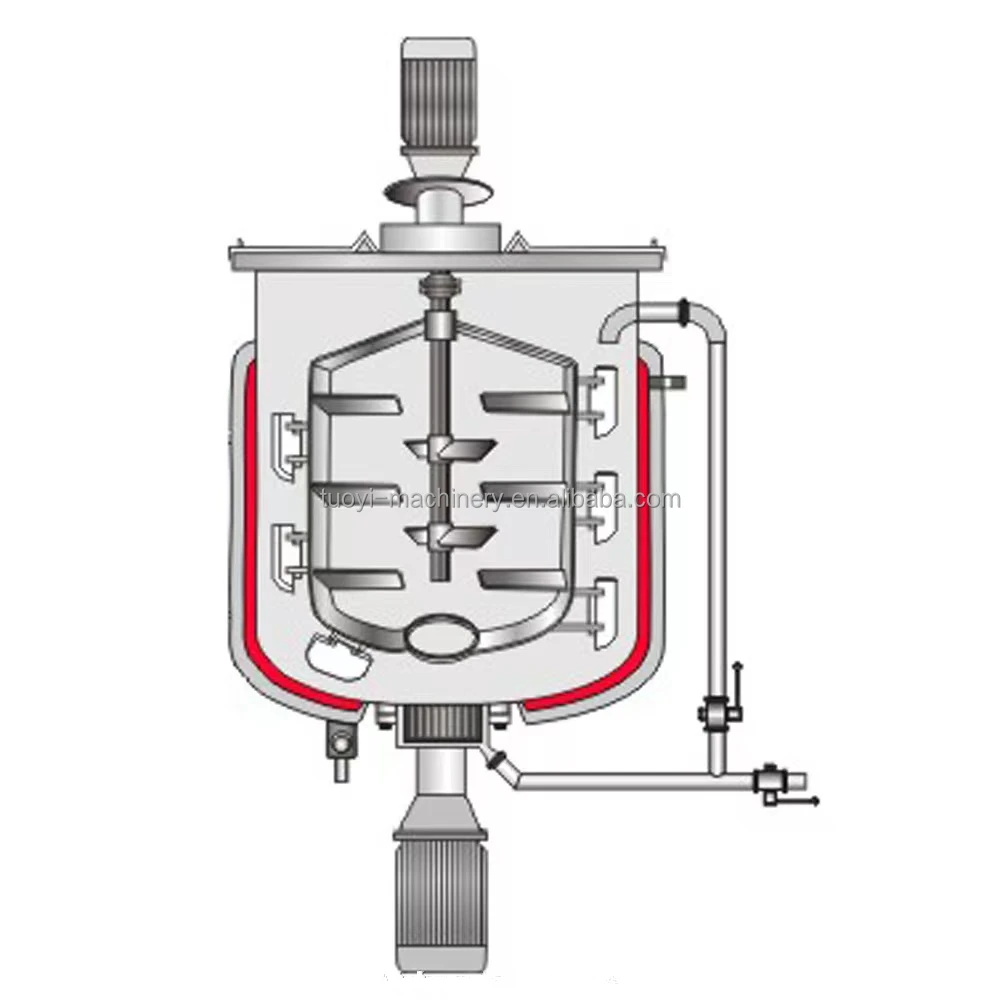

This Vacuum Emulsifying Machine has easy operation, steady capability, good homogeneity, high efficiency, reasonable structure,high automation level and easily clean.

Unidirectional mixing or bidirectional mixing for customer's option.The mixing paddle design will be customized according to different kinds of products, To make sure it has good mixing effect.

High Shear Homogenizer teethed type rotor and stator assembly installed on the vessel bottom or on the top As optional items, several interchangeable configurations are available.

TY-300L Vacuum Emulsifying Mixer | |||

NO | Name | Technical parameters | Main brand |

1 | Main pot | Design volume: 375L Working volume:300L |

|

2 | Material &Thickness | Inner Layer:8mm (Polishing: 400MESH) Cover: 6mm, Stirring blade: 12mm, | SUS316L |

Middle Layer: 8mm; | SUS 304-2B | ||

Cotton insulation is expanded perlite |

| ||

Out Layer: 3mm (Polishing:400MESH) | SUS 304-2B | ||

Pot Bottom: Discharge hole, Temperature detection hole. |

| ||

3 | Stirring Way | Anchor agitator stirring scraper | SUS316L |

Scraping blade PTFE material, snapping stirring the pot wall, so the material does not stick pot wall mixed. |

| ||

Bottom temperature probe bulb to 20mm can accurately measure the temperature of the material. Temperature Sensor. | Omron | ||

Bottom-mixing Motor: 5.5 KW; | ABB /Siemens | ||

Bottom-mixing Frequency control: 0~63r/min | Panasonic | ||

4 | Homogeneous | Homogenizer as SUS 316L solid stainless steel material, by laser machining process from several species such as helical vane cavity structure and the special work in strict accordance with Japan technology to produce high precision, strong shear. | Japan Technology |

Homogenizer Motor :7.5KW | ABB/Siemens | ||

Homogenizer Inverter: 0-3600r/min | Panasonic | ||

5 | Sealing | Dharma Blue sealed with silicone rubber O-ring | Burgmann |

Homogenizer using the world famous German high-speed Mechanical seal Burgmann. |

Burgmann | ||

6 | Heating way | Electric / Steam heating, Water test pressure 0.4Mpa,working Pressure<0.15-0.25Mpa |

|

7 | Discharge way | Spout with sanitary pot bottom valve. |

|

Can through Variety pump discharge. |

| ||

8 | Electric Box | Electrical control box for the SUS304-2B, Appearance of sand board. |

|

Main Eectric elements of world brand; Button by Japan Fuji, Schneider or Omron for Meter and Sensor. One the control panel should be able to adjust and display the stirring speed, The pot temperature, The Temperature of the upper and lower limits control, Emulsification time and slow mixing time settings and other functions. | Main electric Schneider | ||

Net weight | 1350kg(Only for standard equipment) |

| |

Power V. | 480V,60HZ |

| |

GMP Standard | Machine platform is welded stainless steel square tube. Welding surface polishing treatment. SUS304-2B Prevent slip Plate on the stirs and platform. | ||

Partner

Packing & Shipping

FAQ

Contact us