Штамповка под заказ сверхмощные зажимные ремни с храповым механизмом для шин 2 дюйма 50 мм т желтая цинковая Зажимная

- Категория: Ratchet Tie Downs >>>

- Поставщик: Changzhou,Haojun,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 405.93 $* | 425.58 $* |

| Aug-19-2025 | 401.9 $* | 421.83 $* |

| Jul-19-2025 | 337.18 $* | 354.58 $* |

| Jun-19-2025 | 394.77 $* | 414.6 $* |

| May-19-2025 | 343.30 $* | 360.46 $* |

| Apr-19-2025 | 388.30 $* | 407.84 $* |

| Mar-19-2025 | 384.37 $* | 403.16 $* |

| Feb-19-2025 | 381.55 $* | 400.2 $* |

| Jan-19-2025 | 377.72 $* | 396.42 $* |

Характеристики

Product Description

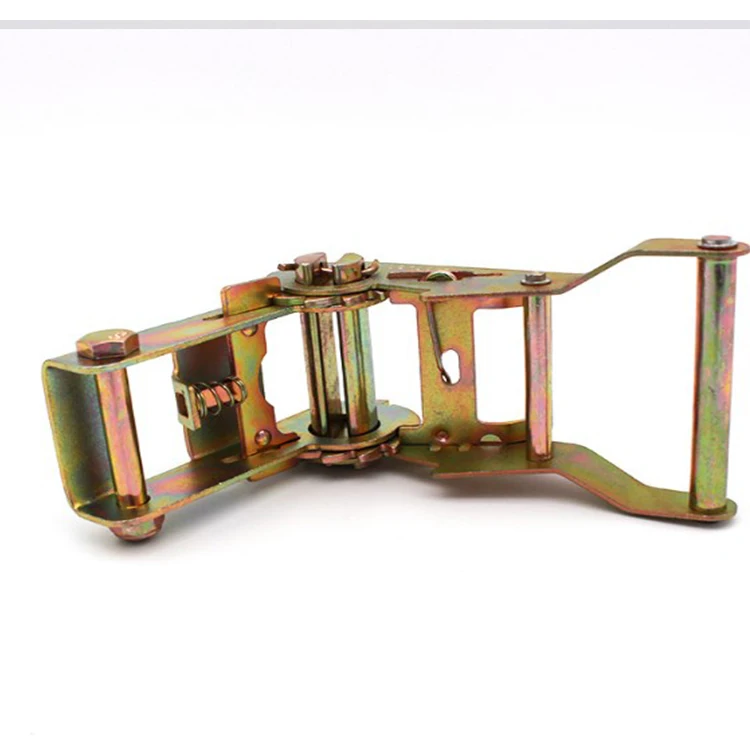

Customized Stamping Customized Heavy Duty Ratchet Tie down Straps for Tire Secure/ 2INCH 50mm 2T Buckle Yellow Zinc Ratchet Buckle Tie Down

Products Details

Product Feature

1.Carefully selected quality materials.

2. After strict inspection of the production process.

3.The bearing capacity is strong,not easy to break.

4.Encryption needle and thread.

5.The operation is simple.

6.Full inspection before shipment.

Applications

Product Paramenters

Item | Description |

Belt Material | Polyester |

Size | 2 inches |

Capacity | 5000kgs/3000kgs |

Material | Steel buckle |

Finish | Zinc Plated |

MOQ | 1 sets |

Application | Making Cargo Lashing Strap |

Width | 50mm/2'' |

Break Strength | 5000 KG |

Type | Locking Buckle Cargo Lashing Straps Tie |

Usage | Securing Cargo |

Ratchet Handle | Ratchet Handle |

Sample | Avaiable |

Popular color | Orange or customized |

Surface Treatment

Surface Finish | Material Avaiable |

Machined | All metals |

Smooth | All metals+Plastic (e.g aluminum, steel,nylon, ABS) |

Powder Coating | All metals ( e.g aluminum, steel) |

Brushing | All metals ( e.g aluminum, steel) |

Anodized Hardcoating | Aluminum and Titanium alloys |

Electropolishing | Metal+plastic (e.g aluminum, ABS) |

Bead Blasting | Aluminum and Titanium alloys |

Anodized Clear or Color | Aluminum and Titanium alloys |

Chrome /Zinc/Nickel Plating | Steel and Brass |

Company Introduction

Changzhou Haojun Technology Co., Ltd locates in west Shanghai,focus on providing one stop solutions for metal and plastic products.

We are committed to help customer realize the concepts and designs with support of our engineering and manufacturing advantages that includes projects and processes as :

---Casting and Forging

---CNC Machining

---Stamping and sheet metal fabrication

---Springs

---Plastic injection molding

1.Stamping Workshop

2.CNC Machining Workshop

3.Casting Workshop

4. Forging Workshop

5.Quality Control

1) Checking the raw material after they reach our factory

2) Check the details before production

3) Full inspection and routing inspection during mass production

4)Checking the goods after finished

5)Checking the goods before shipment

2) Check the details before production

3) Full inspection and routing inspection during mass production

4)Checking the goods after finished

5)Checking the goods before shipment

Packing&Shipping

Fully packed well before shipment to avoid damage during shipment.

We can also packing as per customer's requirement.

---Plastic or Bubble bags

---Small cartons

---If needed for heavy products, we will use pallet or wooden box .

Certifications

Our Advantages

1) Design assistance and full engineering support .

2) Professional at OEM & ODM parts .

3) After sales service.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8)Perfect for low to mid sized production volumes.

2) Professional at OEM & ODM parts .

3) After sales service.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8)Perfect for low to mid sized production volumes.

FAQ

Q1: Where can I get product & price information?

A: Send us an inquiry e-mail, we will contact you as we receive your mail.

Q2: How long can I get the sample?

A: Depends on your specific items, within 15 days is required generally.

Q3: What's kinds of information you need for a quote?

A: Kindly please provide the product drawing in PDF or .IGS or .STEP.

Q4: what's the payment terms?

A: We accept 30% as payment deposit and balance paid before shipment.

Q5. Are you a trading company or factory?

A: We are a direct factory with experienced engineers and employees .

Q6. What shall we do if we do not have drawings?

A. Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts

with dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q7. Can we get some samples before mass production?

A: Absolutely

Q8. Will my drawings be safe after sending to you?

A: Yes, we will keep them well and not release to the third party without your permission.

Q9: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.

A: Send us an inquiry e-mail, we will contact you as we receive your mail.

Q2: How long can I get the sample?

A: Depends on your specific items, within 15 days is required generally.

Q3: What's kinds of information you need for a quote?

A: Kindly please provide the product drawing in PDF or .IGS or .STEP.

Q4: what's the payment terms?

A: We accept 30% as payment deposit and balance paid before shipment.

Q5. Are you a trading company or factory?

A: We are a direct factory with experienced engineers and employees .

Q6. What shall we do if we do not have drawings?

A. Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts

with dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q7. Can we get some samples before mass production?

A: Absolutely

Q8. Will my drawings be safe after sending to you?

A: Yes, we will keep them well and not release to the third party without your permission.

Q9: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.