Мощный рифленый шлифовальный круг с обработкой сапфира/циркония алмазный CBN

- Категория: Grinding Wheels >>>

- Поставщик: Sichuan,Porous,Metal,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 171.92 $* | 180.70 $* |

| Aug-16-2025 | 170.32 $* | 179.6 $* |

| Jul-16-2025 | 143.63 $* | 150.28 $* |

| Jun-16-2025 | 167.24 $* | 175.46 $* |

| May-16-2025 | 145.80 $* | 152.18 $* |

| Apr-16-2025 | 164.49 $* | 172.66 $* |

| Mar-16-2025 | 163.0 $* | 171.64 $* |

| Feb-16-2025 | 161.37 $* | 169.56 $* |

| Jan-16-2025 | 160.86 $* | 168.63 $* |

Характеристики

Products Description

Technical advantages

Higher than the blade

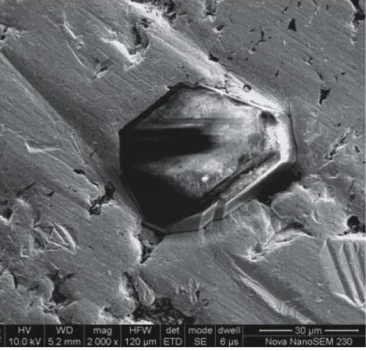

1. Self-consistent hole-making technology at the working surface of grinding wheel

2. High edge height technology

3.Self-sharpening technology

4. Coupling technology of high conformability and easy repair

5. High-strength metallurgy combined with

internal interface liquid phase full equilibrium diffusion integral molding technology

internal interface liquid phase full equilibrium diffusion integral molding technology

Material advantages

1. New cermet bond

Through independent research and development, Sap overcame the technical difficulties of combining the binder with diamond/CBN abrasive grains, and took the lead in developing the cermet bond in China.

Metal-ceramic bond contains metal bond and covalent bond (ceramic bond is covalent bond). The advantages of metal bond on abrasive holding force and ceramic bond on abrasive self-sharpening can be integrated by adjusting the ratio of the two in the bond. The Sap grinding wheel is characterized by high sharpness, high shape retention, easy repair and long service life.

Metal-ceramic bond contains metal bond and covalent bond (ceramic bond is covalent bond). The advantages of metal bond on abrasive holding force and ceramic bond on abrasive self-sharpening can be integrated by adjusting the ratio of the two in the bond. The Sap grinding wheel is characterized by high sharpness, high shape retention, easy repair and long service life.

2. Optimized combination of ultra-hard abrasive particles with high comprehensive performance

3. Full metallurgical bonding of working layer/substrate

4. Lightweight, high thermal conductivity, corrosion resistant substrate

5. Matching of physical, chemical and mechanical properties of integral grinding wheel

5. Matching of physical, chemical and mechanical properties of integral grinding wheel

Quality inspection

We have professional quality inspection equipment to ensure that every product is of high quality. At the same time, we accept double quality inspection before leaving the factory, and provide corresponding inspection reports to ensure product quantity and data.

Production and testing

Application direction

Carbide processing

High-precision machining of various tools

Why Choose Us

1. Well-equipped, stable and high-quality raw material supply chain, to provide customers with the best quality products.

2. Strict quality inspection process and professional certificate testing to ensure the quality level of the final product.

3. Excellent sales team can provide customers with integrated and professional services.

4. Accept various OEM & ODM services to meet the different needs of different customers,low MOQ.

5. Professional supplier and manufacturer, an integrated enterprise integrating production and sales, providing customers with one-stop service.

2. Strict quality inspection process and professional certificate testing to ensure the quality level of the final product.

3. Excellent sales team can provide customers with integrated and professional services.

4. Accept various OEM & ODM services to meet the different needs of different customers,low MOQ.

5. Professional supplier and manufacturer, an integrated enterprise integrating production and sales, providing customers with one-stop service.

Sichuan Porous Metal Technology co,LTD, established in 2022,specializes in product research and development, production and sales with various metal powders and ceramic atomizing cores as the core. Our main products are electronic metal ceramic atomizing core, high-purity titanium powder, titanium hydride powder, MIM powder, 3D printing metal powder,grinding wheel, iron-based, nickel-based powder, tungsten carbide (WC), chromium carbide (Cr3C2) thermal spray powder, etc.And best selling in Australia, Europe, Japan, India and other countries and regions. Those products are widely used in 3D printing, product coating, powder metallurgy, biological materials and other fields.

We could provide customized products and differentiated services to a high quality level.And have a strict quality control system, professional R&D and sales team,stable logistics network.

We aim to communicate and cooperate with our customer, convey the core concept of our company, and establish a long-term cooperative relationship with them to achieve win-win and development for both parties.

We could provide customized products and differentiated services to a high quality level.And have a strict quality control system, professional R&D and sales team,stable logistics network.

We aim to communicate and cooperate with our customer, convey the core concept of our company, and establish a long-term cooperative relationship with them to achieve win-win and development for both parties.

FAQ

1.Are you a trading company or a manufacturer?

RE: We are a company integrating industry and trade. Our company is located in Chengdu, and our factory is in Deyang, with corresponding R&D and production capabilities.At the same time, we have long-term cooperation with two suppliers to ensure customer needs.

2. Do you accept customization?

RE: We can provide corresponding customized solutions according to the specific needs of customers.

3. Can you provide samples?

RE: We can provide samples to customers and send them to consumers in time by express.

4. How is your production capacity ?and whether it can meet customer needs in a timely manner.

RE: We have our own factory in Deyang, which can produce the products required by customers in time and have sufficient production capacity.

5.How long is your lead time?

RE: Within 50kg, can be shipped out from the factory within 15 days. More than 50 kg, the corresponding time needs to be negotiated according to the weight of the product.

6.What is your terms of payment ?

RE: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment. irrevocable LC at sight.

7.Do you have OEM or ODM service of those Powders?

Re: Sure. If needed, we can customize those powders for you.

8.How can you guarantee the goods you offer is qualified of metal Powder?

Re: All the goods are inspected before shipment. If the goods can't come to the quality we promise, you can ask for refund.

RE: We are a company integrating industry and trade. Our company is located in Chengdu, and our factory is in Deyang, with corresponding R&D and production capabilities.At the same time, we have long-term cooperation with two suppliers to ensure customer needs.

2. Do you accept customization?

RE: We can provide corresponding customized solutions according to the specific needs of customers.

3. Can you provide samples?

RE: We can provide samples to customers and send them to consumers in time by express.

4. How is your production capacity ?and whether it can meet customer needs in a timely manner.

RE: We have our own factory in Deyang, which can produce the products required by customers in time and have sufficient production capacity.

5.How long is your lead time?

RE: Within 50kg, can be shipped out from the factory within 15 days. More than 50 kg, the corresponding time needs to be negotiated according to the weight of the product.

6.What is your terms of payment ?

RE: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment. irrevocable LC at sight.

7.Do you have OEM or ODM service of those Powders?

Re: Sure. If needed, we can customize those powders for you.

8.How can you guarantee the goods you offer is qualified of metal Powder?

Re: All the goods are inspected before shipment. If the goods can't come to the quality we promise, you can ask for refund.

Похожие товары

Алмазный шлифовальный диск для гранита 105 мм 115 мм 125 мм

US $5.00-$15.00

4-дюймовый режущий диск

US $0.10-$1.00

Параллельный Алмазный/CBN шлифовальный круг

US $16.00-$17.00

Алмазный шлифовальный диск для гранита 105 мм 115 мм 125 мм

US $5.00-$15.00