Профессиональные машины для производства гидратированного Лайма растений с

- Категория: Cement Making Machinery >>>

- Поставщик: Zhengzhou,DynNor,Industrial,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 136850.69 $* | 143693.9 $* |

| Aug-19-2025 | 135700.95 $* | 142485.53 $* |

| Jul-19-2025 | 113850.34 $* | 119543.52 $* |

| Jun-19-2025 | 133400.33 $* | 140070.68 $* |

| May-19-2025 | 116150.53 $* | 121958.70 $* |

| Apr-19-2025 | 131100.47 $* | 137655.48 $* |

| Mar-19-2025 | 129950.4 $* | 136448.29 $* |

| Feb-19-2025 | 128800.8 $* | 135240.1 $* |

| Jan-19-2025 | 127650.39 $* | 134033.72 $* |

Характеристики

Hydrated Lime Machines to Produce Ca(OH)2 Power

for Construction, metallurgy and water treatment purposes

Our Lime hydration System had served numerous customers at home and abroad for over 20 years, system overall performance has been proven to be very reliable for various quality of lime(from shaft kilns or rotary kilns). the output Ca(OH)2 can meet requirements of metallurgy use and construction paint purposes. output moisture level and output sizes are adjustable according to different applying purposes; our experienced engineers are 24/7 available to help you achieve the optimal production performance if your lime raw materials are different sources and not consistent.

We keep improving the lime slaker system based on latest technologies and ever-changing market demands. Give us a call or leave a message now if you need a lime slaking unit.

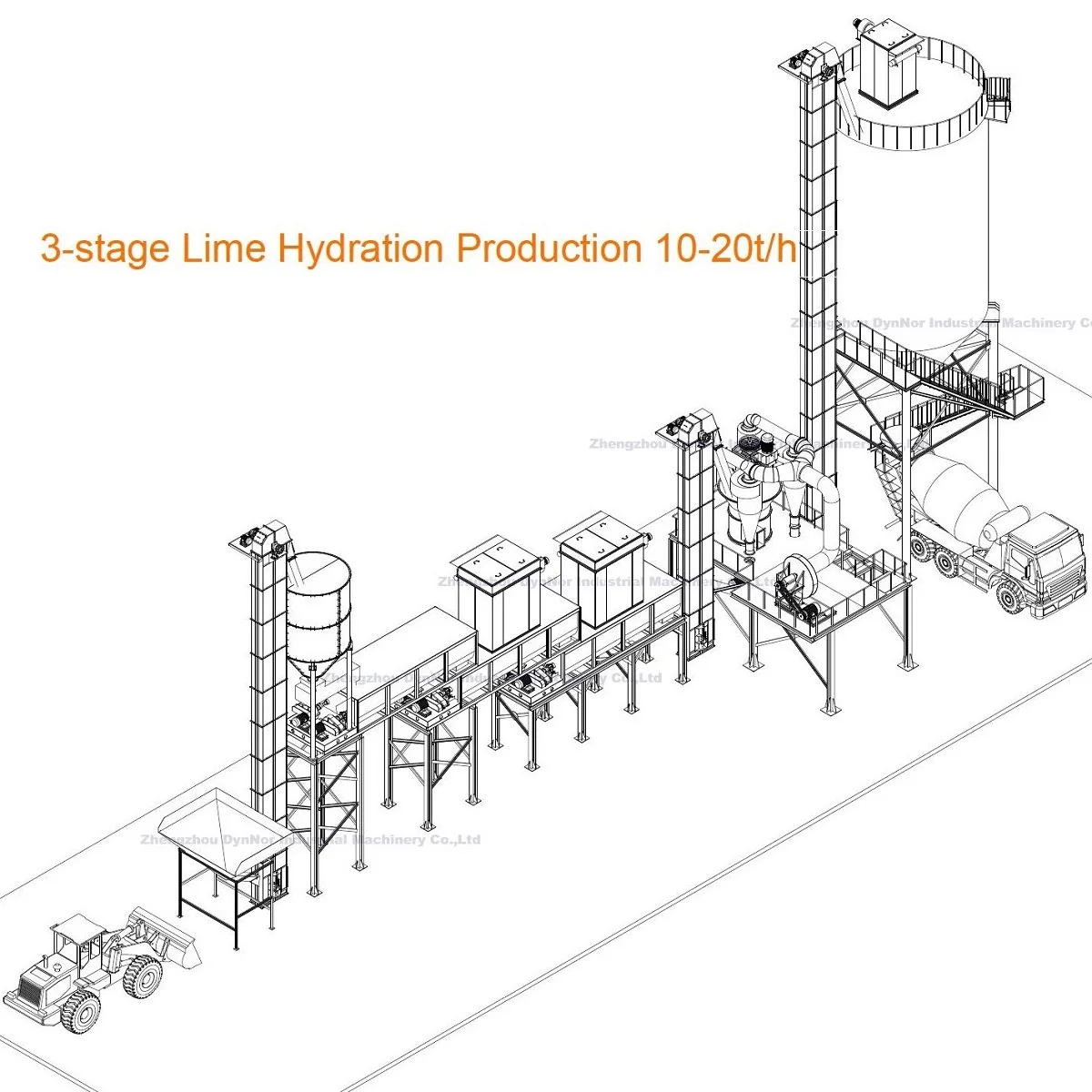

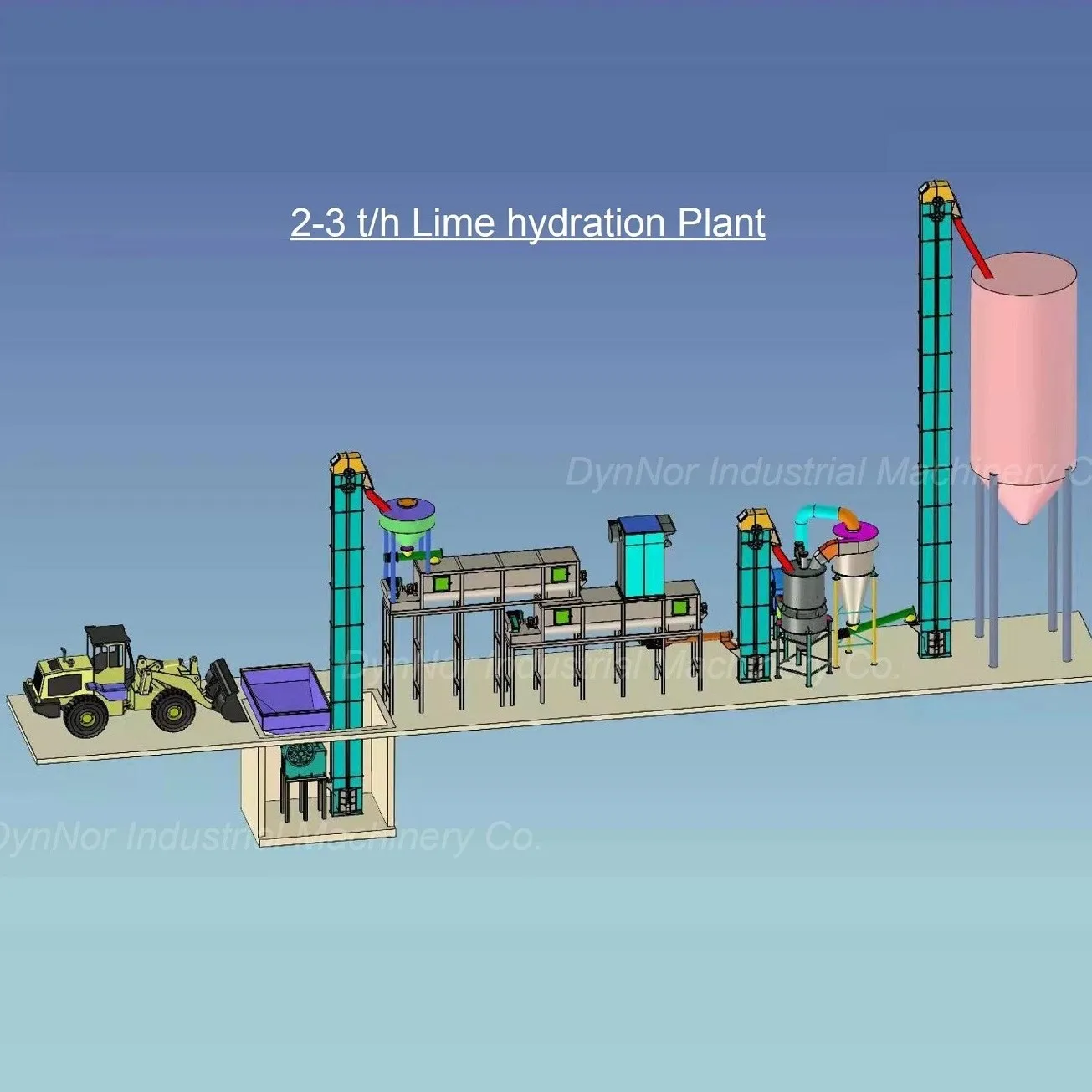

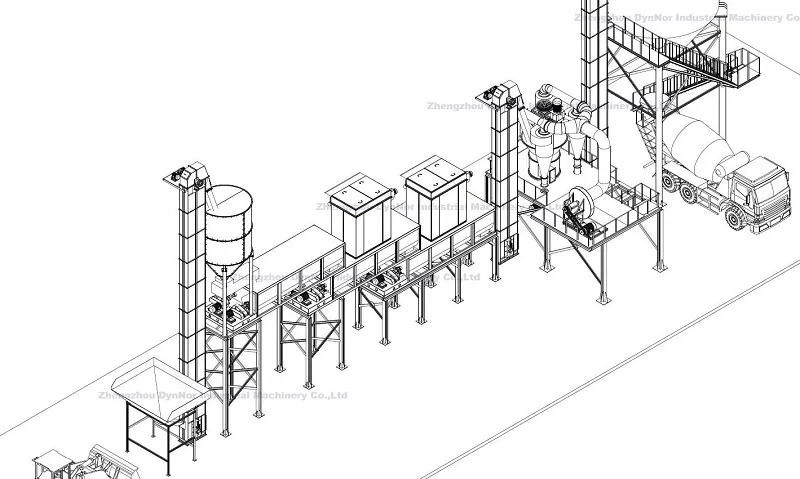

Hydrated Lime Plant Layout Plans

The hydrator system may have different layout plans and optional equipments based on customers' demand or limitation of floor area or workshop.

- Tower type layout:

This layout could save floor space, and it is normally integrated with a water tank that is heated by exhaust steam from the slaking process. Heated water could effectively increase the slaking performance in many cases and improve product quality. drawback is that size of water tank is quite big and thus would increase the machine cost and shipping cost for overseas projects.

- Staircase Layout:

This is the conventional layout, but still very popular in the industry. it's very reliable and easy for maintenance &operation. drawback is that it requires a larger floor area for installation.

Description of 10 t/h hydrated lime plant:

Description of 10 t/h hydrated lime plant:

>> List of Equipment:

| 1.) Crusher Hopper | 2.) Jaw Crusher | 3.) Bucket Elevator | 4.) Lime Slaker Hopper |

| 5.) Screw Feeder | 6.) Lime Slaker I | 7.) Lime Slaker II | 8.) Lime Slaker III |

| 9.) Dust Collector | 10.) Screw Discharge | 11.) Bucket Elevator | 12.) Powder Separator |

>> Floor Area Required for Installation: Length: 31.5m, Width: 4.5m

>> Raw Material Crushing Pit: 3.0m x4.5m x4m (Width x length x Depth)

>> Output sizes: from 100 to 600 mesh (adjustable)

>> Total Power Installed: 280Kw/h

When the hydration system is started, the transmission mechanism drives the stirring mechanism to stir, and the calcium oxide enters the first hydrator’s chamber through the belt weighing feeder. The PLC control system controls the water spray device to start spraying water. The material and water are pushed to the chamber of the second hydrator by special-angled blades on the shaft while being fully mixed. The second-stage mixing shaft is also equipped with special-angled blades, which push the materials to the third-stage hydrator chamber while fully stirring. The three-stage mixing shaft is also equipped with special-angled blades, which separates the over-burned lime particles in the material from the outer layer of calcium hydroxide while discharging the hydrated product. The temperature measuring element on the hydrator body transmits the temperature of the material in the hydrator chamber to the PLC control system for monitoring in real time, and adjusts the water supply in time. The steam along with some hydrated lime particles generated by the material reaction is filtered by the pulse bag filter, lime particles are released back to the hydrator while clean steam &air is discharged. Finally, the product (calcium hydroxide) is sent to the lime powder separator through the material conveying equipment to control output powder sizing.

The reaction of quicklime (calcium oxide) with water is called the hydration of quicklime. Mainly calcium oxide (CaO) in quicklime reacts with water (H2O) to form calcium hydroxide -Ca(OH)2. The reaction of calcium oxide and water is a strong exothermic reaction. During the reaction process, a large amount of steam is generated due to heat generation. Therefore, the reaction of calcium oxide and water is a three-phase reaction involving vapor, liquid and solid.

Reaction equation of quicklime hydration: CaO + H2O = Ca(OH )2 + 66.1kJ

From the above equation, it can be obtained that: 1Kg of CaO requires 18/56=0.321 (Kg) of water for complete hydration and releases 66.1×1000/56=1180.357 (KJ) of heat. According to experience, the reaction temperature is controlled at about 100 degrees, so the system needs additional water to transfer the heat generated by the reaction.

The heat generated from 1 mol CaO hydration is Q1=66.1 (KJ)

The heat required to heat 1 mol CaO from 0°C to 100°C is Q2=44.1×100/1000=4.41 (KJ)

The heat required to heat 1 mol of water from 0°C to 100°C is Q3= 75.4×100/1000=7.54 (KJ)

The heat required to evaporate 1 mol of water Q4=40.6 (KJ)

Assuming that 1 mol of CaO is completely Hydrated, the steam used to transfer heat is X mol, and according to the heat balance:

(X+1)×Q3+X×Q4+Q2=Q1

X=1.12 (mol)

It can be deduced from the above that, without considering the heat loss and the purity of the quicklime, it is theoretically necessary to add (1+1.12)×18/56=0.71kg of water for every 1kg of calcium oxide to produce 0.36kg of steam to be removed from the hydration.