Китайский производитель пластиковый транспортный роликовый Конвейерный ролик скэп закрытый

- Категория: Rubber Rollers >>>

- Поставщик: Shenzhen,Xinhansheng,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.74 $* | 0.94 $* |

| Aug-16-2025 | 0.89 $* | 0.44 $* |

| Jul-16-2025 | 0.59 $* | 0.36 $* |

| Jun-16-2025 | 0.59 $* | 0.54 $* |

| May-16-2025 | 0.25 $* | 0.88 $* |

| Apr-16-2025 | 0.46 $* | 0.50 $* |

| Mar-16-2025 | 0.78 $* | 0.39 $* |

| Feb-16-2025 | 0.6 $* | 0.56 $* |

| Jan-16-2025 | 0.81 $* | 0.19 $* |

Характеристики

Product parameters

Products | conveyor rollers | ||||||

Material of surface | HCPP, NPP, PPG, UPE, PVDF, soft PP, Santoprene, PTFE, SUS, EPDM, NBR, PU | ||||||

Material of shaft | SUS, Ti, fibre rod, carbon rod, PEEK, PP coated SS | ||||||

OD range of surface | ¢10~60mm | ||||||

Length range of surface | 50~1800mm | ||||||

OD range of shaft | ¢4~20mm | ||||||

Range of Total length | 100~2000mm | ||||||

Machining process | Precision cutting machines. Lathes. Milling machines. Grinders. Automated mechanical systems. | ||||||

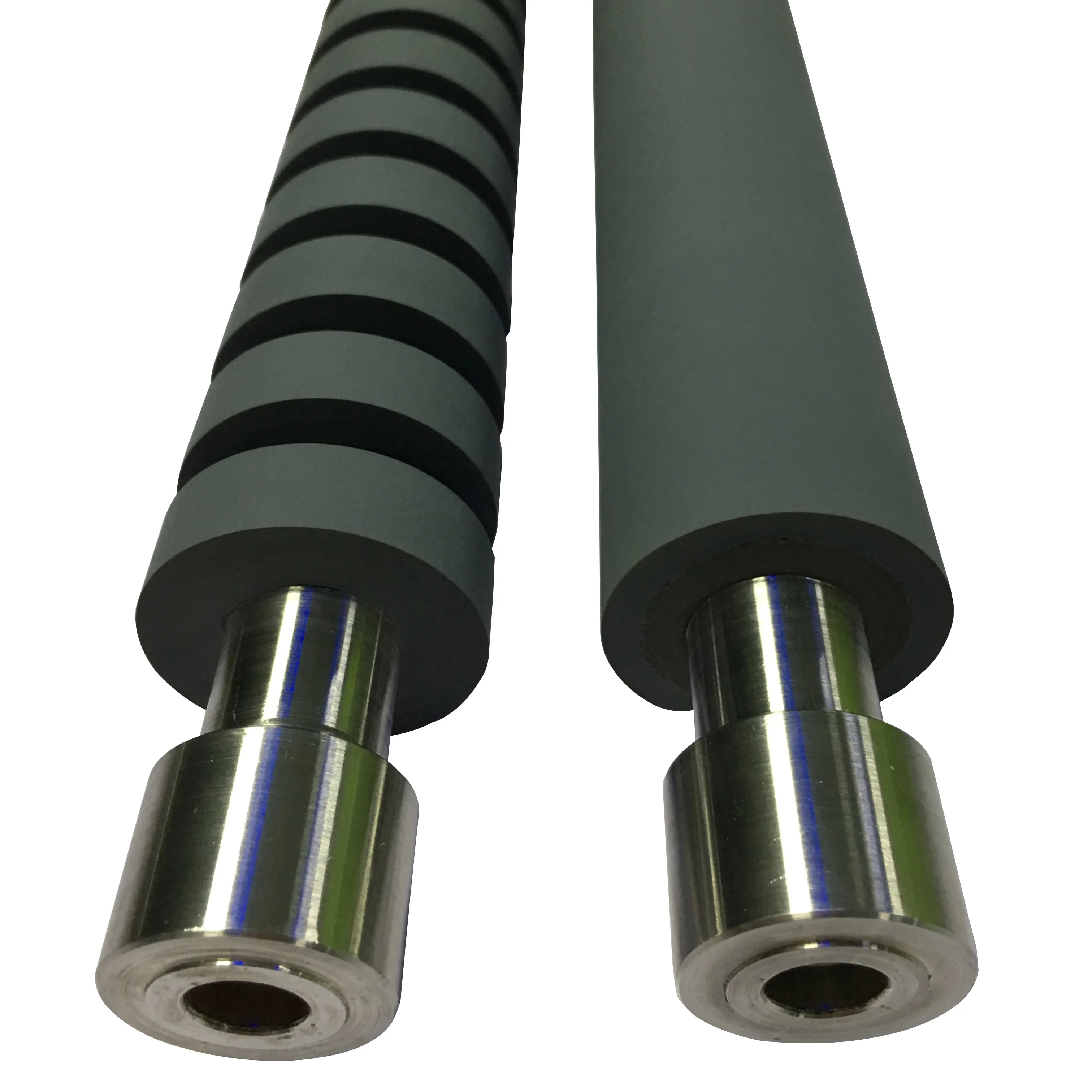

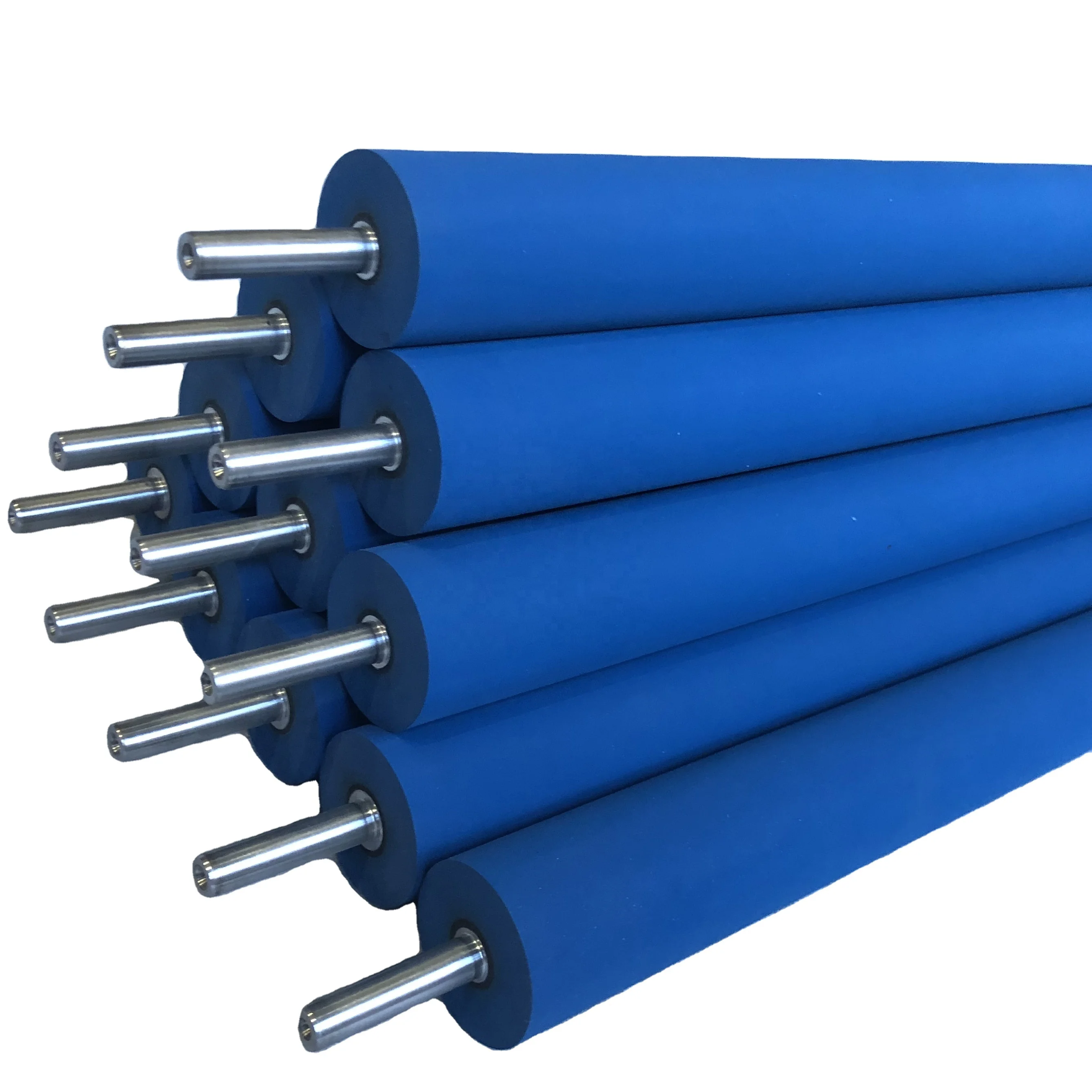

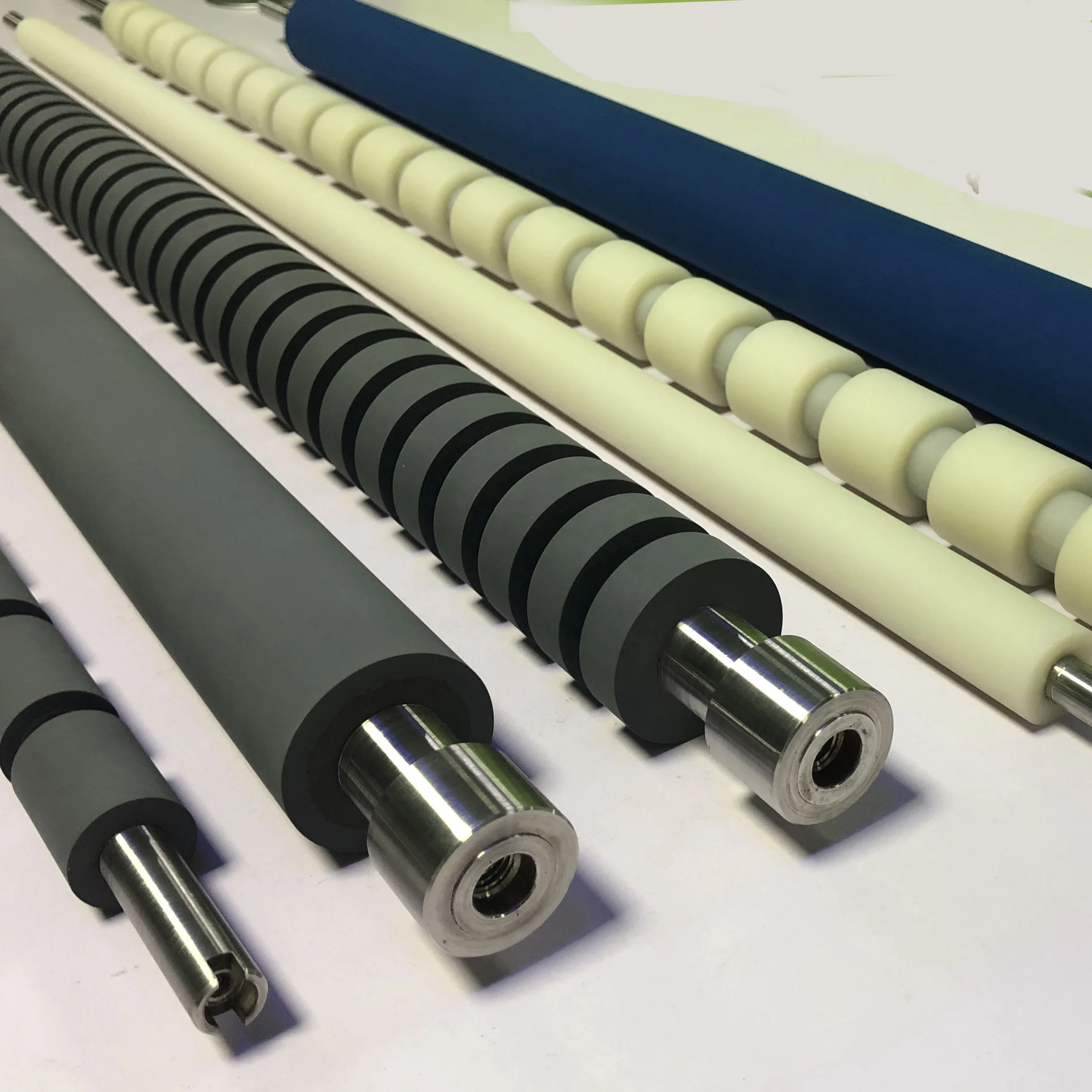

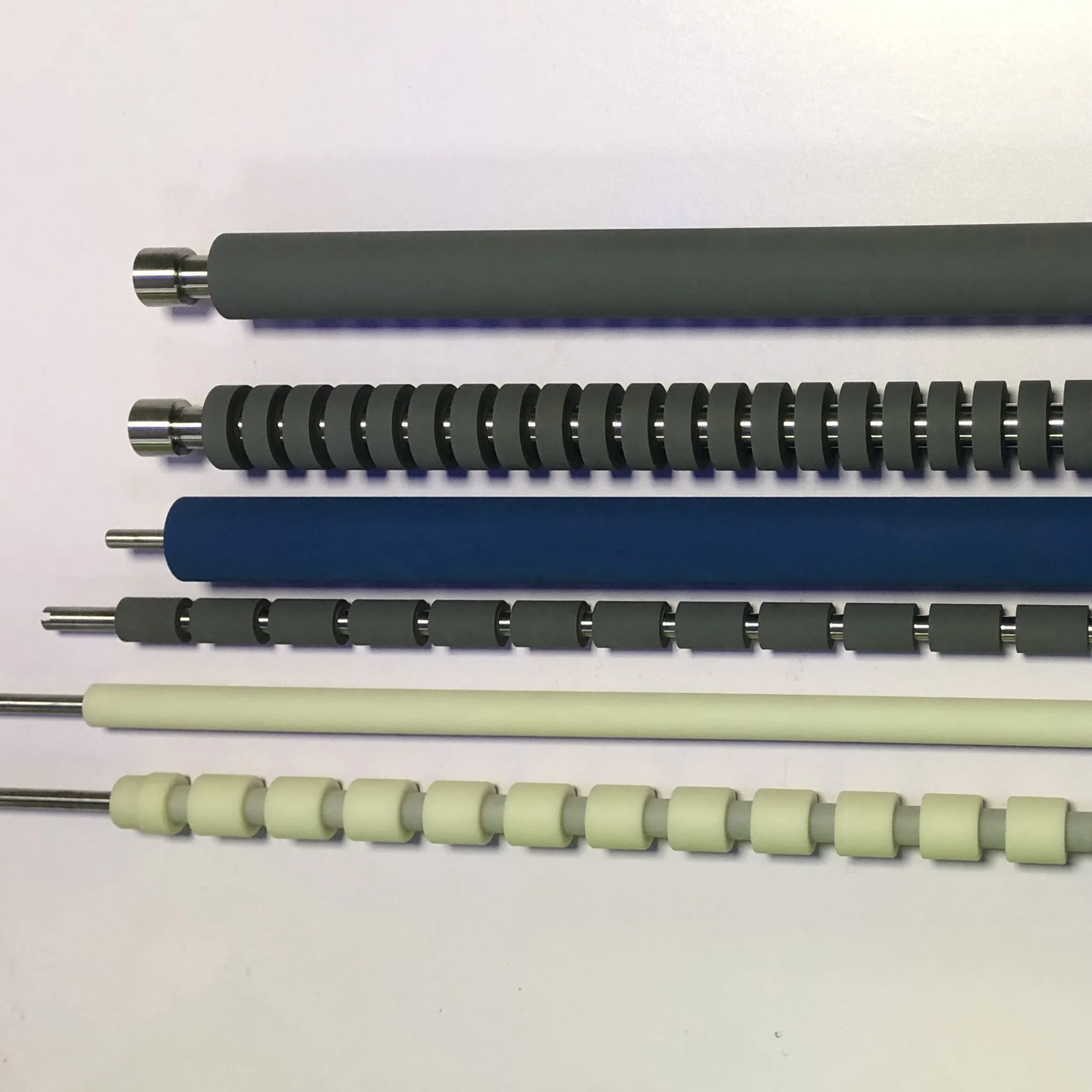

Product Display

The company's existing professional rollers: HCPP, NPP, PPH, German gray PP, soft PP (thermorun), UPE, PVDF, Teflon, Santoprene , SUS, EPDM rubber rollers, NBR rubber rollers,, PU rubber rollers, etc.

HCPP roller

temperature resistance under 80 degree

shaft can be customized

NPP roller

temperature resistance under 100

degree

shaft can be customized

German gray PP

temperature resistance under 110 degree

shaft can be customized

soft PP (thermorun) roller

Shore hardness: 55A

chemical resistant

PVDF roller

Suitable for glass cleaning and solar industry

SUS roller

SUS304 roller

SUS316L roller

Ti2 roller

EPDM rubber roller

Shore hardness: 45A~60A

chemical resistant

customized according to drawing

PU rubber roller

Shore hardness: 45A~60A

good wear resistance

Sticky Roller, Cleaning Roller, Subfilm Roller

NBR rubber roller

Shore hardness: 45A~60A

good wear resistance

customized according to drawing

customized according to drawing

Application field

A professional team with 10+ years of technical experience is at your service

Spare parts for PCB equipment

DES Machine(FPCB/RIGID),

developing machine, etching machine,

strip machine, PTH Pre&Post treatment,

black hole machine, brown oxide line,

black hole machine, brown oxide line,

desmear machine, OSP machine,

horizontal electroless copper line,

chemical cleaning machine,

loading & unloading machine flexible

loading & unloading machine flexible

Spare parts for LCD equipment

Touchscreen OGS Yellow Equipment,

Membrane Structure Yellow Equipment, Touchscreen Etching Cleaning Equipment,

Etching Cream Washing line,

Glass cleaning equipment,

striping equipment,

LCD Solar etching cleaning equipment, AG glass etching equipment,

CG plate cleaning equipment

Spare parts for Electroplating equipment

Gold plating machine, silver plating machine, industrial waste gas treatment, water treatment, rail production line, copper

rolling machine, oxidation equipment, pure water equipment, sand blasting machine

rolling machine, oxidation equipment, pure water equipment, sand blasting machine

Spare parts for photovoltaic (PV) equipment

Monocrystalline silicon cleaning machine, wafer cleaning machine, silicon wafer cleaning machine, texturing cleaning machine,

polysilicon cleaning machine

polysilicon cleaning machine

Certifications

Companies strictly enforce the ISO9001(2008)international quality certification system

Our factory

The company was committed to provide satisfactory PCB, LCD, Solar PV and other wet

processing equipment spare parts and services.

processing equipment spare parts and services.

Shenzhen Xinhansheng Technology co., Ltd is a professional enterprise in mold designing, manufacturing, production, plastic injection, sales and machine maintenance.

Since 2001, we have developed and produced different kinds of engineering plastic products for

many customers both at home and abroad, such as: Southeast Asian countries, Africa,USA,Taiwan and so on. Now we have three separate overseas offices in Thailand, South Korea and India. We have received good reputations from our customers.

Our Strength

Professional engineer teams and sales teams Advanced equipment

Fast delivery time One-stop service

High quality and factory price Good after-sales service

High quality and factory price Good after-sales service

FAQ

Q1. We don't have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days, mainly for existing parts assembly and processing products

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, Grinding machine, gear hobbing machine, milling machine, injection molding machine, molding

machine,engraving machine,electrical discharge machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, injection molding, etc.

Q7. What are your main products?

A7. Spare parts: Gears, disk wheel, bushings, nozzles, flow meters, pressure gauges, level switches, screws, handles, other

processing or injection products.

Module products: PPH/HCPP/NPP roller, UPE roller, PVDF roller, SUS roller, thermorun roller, HPVC roller, Teflon coated roller, PU rubber roller, NBR rubber roller, EPDM rubber roller, PVA sponge roller, PP sponge roller, PU sponge roller, PVC sponge roller,spray bar with nozzles, drive shaft, conveyor machine.

Equipment maintenance: mainly for PCB wet process equipment maintenance, brand for UCE, KT, Taesung, Atotech, Schmid, Dooson, TCF, Ampoc, Manz, TTM, etc

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. What are your engineering plastics?

A9. There are many engineering plastics, commonly used are ECTFE, PFA, PTFE, PEEK, UHMWPE, PVDF, PPH, CNL, PPSU, PPS, PC, etc. We

can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 3,500 square meters and has 50+ employees.

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days, mainly for existing parts assembly and processing products

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, Grinding machine, gear hobbing machine, milling machine, injection molding machine, molding

machine,engraving machine,electrical discharge machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, injection molding, etc.

Q7. What are your main products?

A7. Spare parts: Gears, disk wheel, bushings, nozzles, flow meters, pressure gauges, level switches, screws, handles, other

processing or injection products.

Module products: PPH/HCPP/NPP roller, UPE roller, PVDF roller, SUS roller, thermorun roller, HPVC roller, Teflon coated roller, PU rubber roller, NBR rubber roller, EPDM rubber roller, PVA sponge roller, PP sponge roller, PU sponge roller, PVC sponge roller,spray bar with nozzles, drive shaft, conveyor machine.

Equipment maintenance: mainly for PCB wet process equipment maintenance, brand for UCE, KT, Taesung, Atotech, Schmid, Dooson, TCF, Ampoc, Manz, TTM, etc

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. What are your engineering plastics?

A9. There are many engineering plastics, commonly used are ECTFE, PFA, PTFE, PEEK, UHMWPE, PVDF, PPH, CNL, PPSU, PPS, PC, etc. We

can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 3,500 square meters and has 50+ employees.