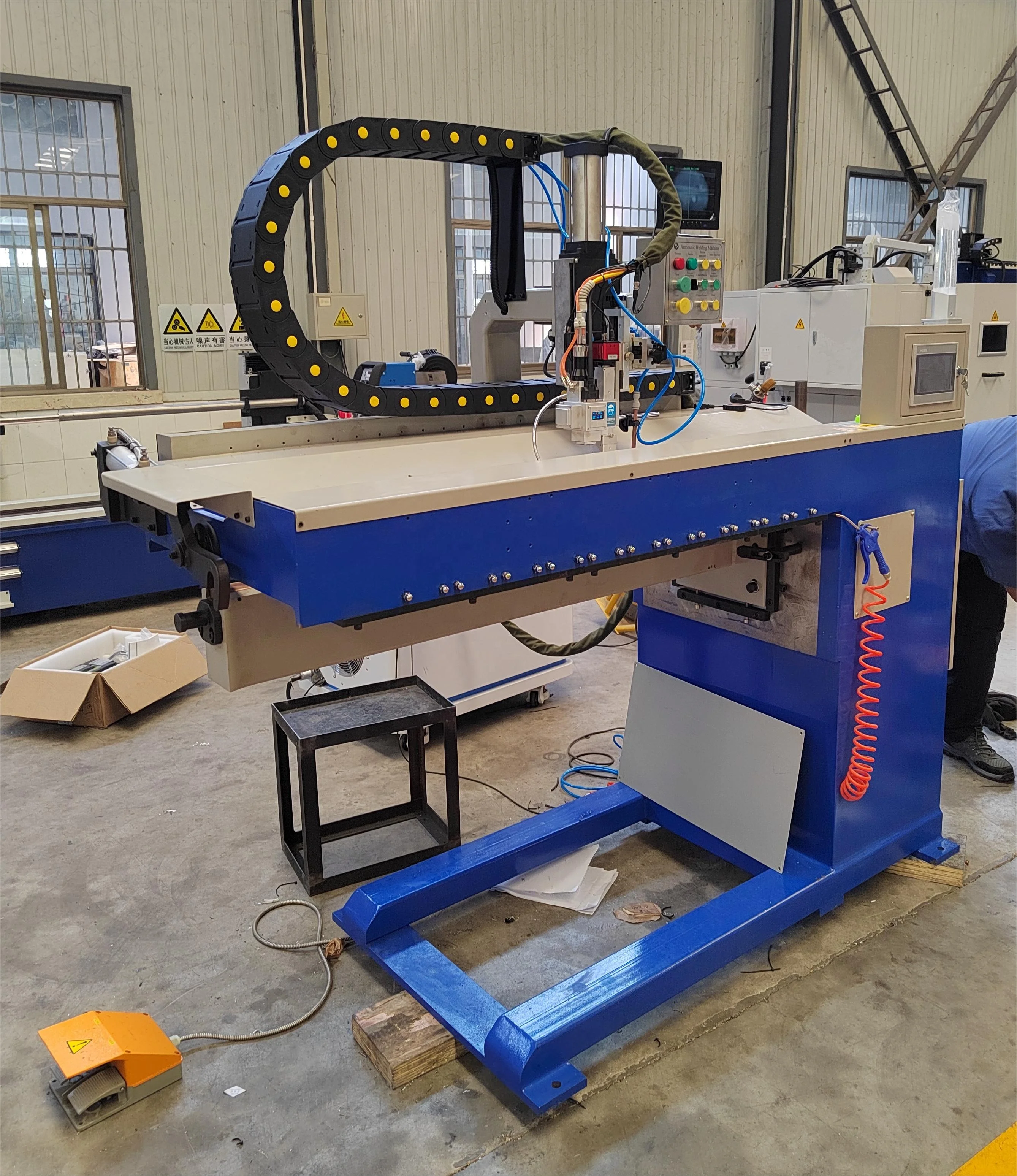

Автоматическая Лазерная Сварка PLC резервуар для воды из нержавеющей стали автоматический Продольный сварочный

- Категория: Seam Welders >>>

- Поставщик: Jinan,Haoyu,Automation,System,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 7619.74 $* | 7771.73 $* |

| Jul-16-2025 | 6179.70 $* | 6303.95 $* |

| Jun-16-2025 | 7499.23 $* | 7649.2 $* |

| May-16-2025 | 7439.44 $* | 7588.21 $* |

| Apr-16-2025 | 5939.29 $* | 6058.25 $* |

| Mar-16-2025 | 7319.54 $* | 7465.63 $* |

| Feb-16-2025 | 7259.90 $* | 7404.21 $* |

| Jan-16-2025 | 7199.76 $* | 7343.50 $* |

Характеристики

PLC control Automatic laser welding stainless steel water tank automatic longitudinal seam welder

Welcome to see more work video on our Yutube Channel

: www.youtube.com/c/haoyucncweld

I Machine features and Application

1.Automatic Weld longitudinal seam on cylinder/tank/pipe/sheet . Welding process will be continual and steady.

2.welding method : laser ,MIG or TIG or Plasma as choose

3. Machine can work continuously for 24-hour.

4.During the welding ,the workpiece is fixed,and the welding torch moving Longitudinally to welding the longitudinal seam , Drive device includes motor, straight rack & pinion and linear guide way.

II Technique Parameters

| No. | Items | specification |

1 | Applicable diameter | customized as the workpiece size range |

2 | Applicable length | <3000mm |

3 | Material thickness | >0.5mm |

4 | Material | Steel or stainless steel or aluminum or cooper or cast iron or other metal |

5 | Control system | Japan Omron PLC and touch screen |

6 | Welding speed | max 2500mm/min |

7 | Welding torch moving range in left-right direction | 100mm |

8 | Welding gun lifting range | 100mm |

9 | Welding power source | Raycus or BTW or named as customer need |

10 | Machine working voltage | 220v 1phase |

Jinan Haoyu Automation system Co., Ltd (relate companies are Jinan Haoyu CNC Machinery Co., Ltd and Singapore company SUN RISING TRADE PTE LTD ) is a high-tech private company located in Jinan City ,Shandong province. We have been a professional manufacturer in the field of welding automation over from 2004

Our products mainly include automatic welding machine, robot welding station, automatic pipe cutting machine, automatic material handling equipment, automatic assembling machine,these machines are widely used in the areas of automobile,construction machinery, railway vehicle, electric power, shipbuilding, pressure container, petrochemical, house appliances and military industry, etc.

We established a long-term cooperative relationship with more than 60 countries and regions, such as Canada,Italy,Australia,United States,India,south America.Our welding machines are recognized by customers with quality and excellent service.the company have obtained CE and ISO certification .

With strong R&D staffs and Strict QC&QA team,so can design and produce as customers' requirements.Our sales team provide perfect support from Pre-sale and after-sale, in-sale.Technology Improvement and perfect products are the eternal pursuit of the company.

Welcome to Visit us at any time!

1.Our first factory was setup in 2004. The factory owner has more than 18 years experiences in welding field.We can make MIG welding machine, cold wire TIG welding machine, hot wire TIG welding machine, submerged arc welding machine,plasma welding machine and laser welding machine.

2.Machines have always been committed with the service idea of customer-centric, supply installation, adjustment, training and maintenance in pre-sales and after-sales service.

3.More stringent quality control system. Most Chinese suppliers are making automatic welding machine mainly for China local market. Their standard only meet domestic normal safe requirement. In order to meet International Standard, we had applied for CE certificates. All technical files are recorded and saved in EU organization.

4.Delivery time assurance measure: the whole process from signing contract to delivering machine is under strict controlled. The system can ensure us deliver the machine timely.

5.And best of all,we have energy to devote to welding industry, and also have patience for each customer.

We have always been committed with the service idea of customer-centric, supply Installation, adjustment, training and maintenance in pre-sales and after-sales service.

1. Pre-sales Service

Before signing contract, customers can get production plan, technical consultant and equipment suggestion and etc.

2. Training service

2.1.Customers can get free technical training in China factory. Mainly training are operate the machine to weld,Basic daily cleaning and maintenance for the machine,Solutions for common hardware problems,online training is ok.

2.2.When Sellers send engineer to Buyer's place for Installation, Commissioning and training in Buyer's place, Buyer should afford the Labour cost of engineers(100.00 USD per person per day),undertake all the relative expenses,like Transportation expenses, accommodation expenses and so on.

2.3 When the Seller's engineer carries out the services in Buyer's place, Buyer shall arrange a Translator that can speak Chinese for Seller's engineer.

3.Pre-shipment inspection system:

3.1 According to the customer‘s shipping details, we will check the products size, weight, spare parts, protective film and other information one by one for each part of goods. If there are any doubtful goods before delivery, quality inspectors will open the package in time and inspect the goods through professional testing equipment to ensure the accuracy of delivery.

3.2.The outer packaging of each goods will also be checked, such as whether the packing is damaged, whether the wooden pallet is fumigated, whether the exported goods are packed with steel strips,etc. To ensure that the goods are not damaged during loading and unloading.

4 .Afer sale service system

4.1 After our customer having received goods, if there are problems caused by the transportation of materials, we would let the customer take photos before unloading, give feedback to the freight forwarder, and make insurance compensation.

4.2. After customers received the goods, if there some quality problems ,production problems. If it is confirmed that there are indeed quality problems.Our QA and QC managers and relevant responsible department will give the reasonable compensation content based on the business contract .

5.We provide Lifelong technology support.

6.Warranty :uausally is one year for main part(PLC,HMI,Gearbox) ,also can be 2~5years as customers requirement

7. My whatsapp/wechat is 0086 15854187090,weclome to inquiry or ask for technology support any time !