Beston Group полностью непрерывные отходы пластика пиролизная установка Отходы Резиновых Шин машина для

- Категория: Rubber Recycling Machinery >>>

- Поставщик: Beston,Group,CO.,LTD

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 357000.0 $* | 374850.91 $* |

| Aug-16-2025 | 354000.84 $* | 371700.62 $* |

| Jul-16-2025 | 297000.51 $* | 311850.44 $* |

| Jun-16-2025 | 348000.55 $* | 365400.66 $* |

| May-16-2025 | 303000.83 $* | 318150.75 $* |

| Apr-16-2025 | 342000.97 $* | 359100.80 $* |

| Mar-16-2025 | 339000.6 $* | 355950.43 $* |

| Feb-16-2025 | 336000.69 $* | 352800.51 $* |

| Jan-16-2025 | 333000.19 $* | 349650.4 $* |

Характеристики

Products Description

▶ What is pyrolysis ?

Pyrolysis is a typical thermal chemical reaction, so the essence of it refers to the recombination of the hydrogen and carbon groups of the raw materials in the oxygen-free environment as the temperature rises.

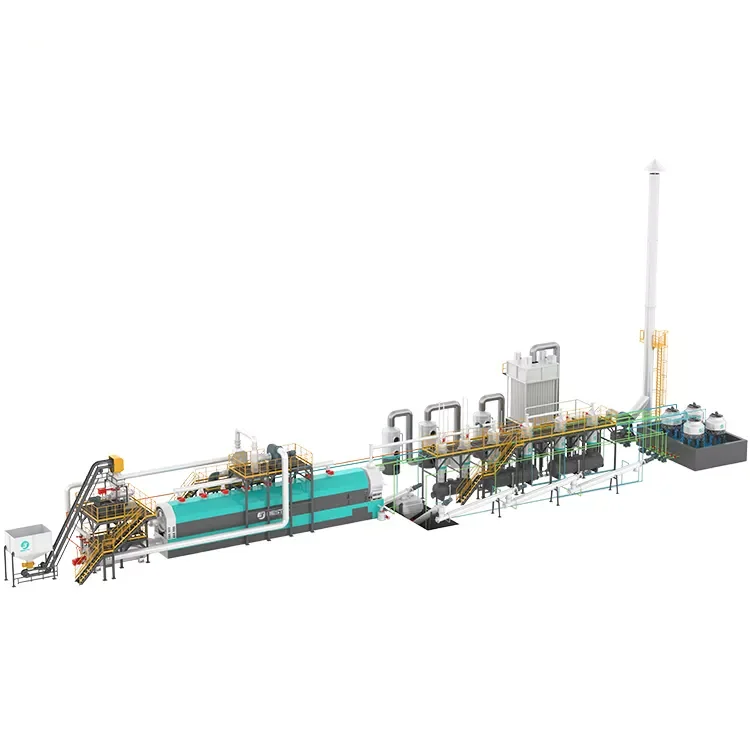

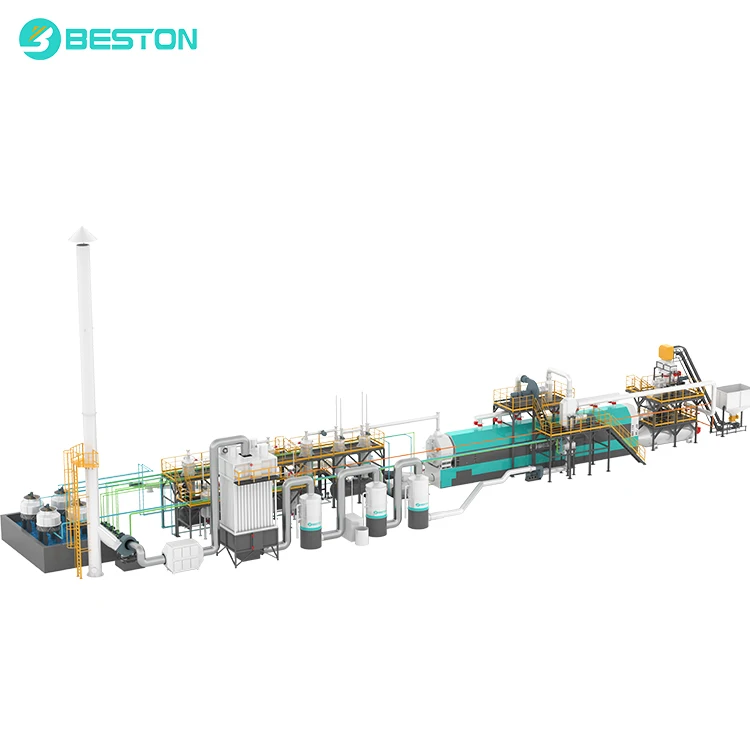

Fully Continuous Pyrolysis Plant

There are two main types of pyrolysis plant for sale in Beston, the fully continuous pyrolysis plant and the small scale pyrolysis plant. Thereinto, the continuous type plants can be divided into semi-continuous and fully continuous type. Following is the specific parameters of all the plants we offer.

Model | BLJ-3 | BLJ-6 | BLJ-10 | BLJ-16 | BLL-30 | ||||

Daily Capacity | 1.5-3T | 6T | 8T-10T | 12-16T | 20-30T | ||||

Working Method | Batch | Semi-Continuous | Fully Continuous | ||||||

Raw Materials | Waste Plastic, Tyre, Rubber, Oil Sludge | ||||||||

Reactor Size | D1.4m*L5m | D2.2m*L6.0m | D2.6m*L6.6m | D2.8m*L7.1m | D1.8m*L22m | ||||

Pattern | Horizontal & Rotary | ||||||||

Heating Materials | Fuel Oil, Natural Gas, LPG, etc. | ||||||||

Installation Area Requst | 20m*8m*8m | 30m*10m*8m | 30m*10m*8m | 40m*10m*8m | 50m*20m*10m | ||||

Weight | 18T | 39T | 44T | 60T | 103T | ||||

Operating Pressure | Slight Positive Pressure | Slight Negative Pressure | |||||||

Cooling Method | Slight Negative Pressure | ||||||||

Life span | 5-8years | ||||||||

Production Process

▶ Raw Materials:

Waste tires/rubber: one of the main components of tires is rubber. Different kinds of waste tires and rubber materials can be used for oil generation, including big car tires, truck tires, OTR tires, motorcycle tires, bicycle tires, rubber cable sheath, rubber soles and all the other kinds of rubber sheets or carpets. For example, the oil yield of big car tires, truck tires and OTR tires is 45%-52%; the oil yield of small car tires, motorcycle, bicycle tires is 35%-40%; the oil yield of rubber cable sheath, rubber soles is about 35%; the oil yield of all kinds of rubber sheets or carpets is 30%; the oil yield of Unclassified rubbers is about 35%.

Waste plastics: except for PVC and PET, almost all the other kinds of plastics can be used for pyrolysis to get oil. For example, the oil yield of pure PP, PE, PS can reach more than 90%; the oil yield of ABS is more than 40%; the oil yield of pure white plastic sheets is about 70%; the oil yield of instant noodles packing bags is 40%; the oil yield of plastic logo is 20%; the oil yield of wet paper-mill waste is 15%-20%; the oil yield of dry paper-mill waste is 50%; the oil yield of plastic household garbage is 30%-50%; the oil yield of pure plastic cable sheath is 80%; the oil yield of pure plastic bags is 30%.

Oil sludge: there are floor oil sludge, tank bottom oil sludge, refinery oil sludge, crude oil sludge, petroleum sludge, engine

oil sludge, etc. The oil content of different sludge materials determines the oil yield.

Waste plastics: except for PVC and PET, almost all the other kinds of plastics can be used for pyrolysis to get oil. For example, the oil yield of pure PP, PE, PS can reach more than 90%; the oil yield of ABS is more than 40%; the oil yield of pure white plastic sheets is about 70%; the oil yield of instant noodles packing bags is 40%; the oil yield of plastic logo is 20%; the oil yield of wet paper-mill waste is 15%-20%; the oil yield of dry paper-mill waste is 50%; the oil yield of plastic household garbage is 30%-50%; the oil yield of pure plastic cable sheath is 80%; the oil yield of pure plastic bags is 30%.

Oil sludge: there are floor oil sludge, tank bottom oil sludge, refinery oil sludge, crude oil sludge, petroleum sludge, engine

oil sludge, etc. The oil content of different sludge materials determines the oil yield.

Waste Tyre

Waste Plastic

Sludge

▶End product

* Pyrolysis oil: 35%-45% * Carbon black: 30%-35% * Steel wire: 8%-15% * Combustible gas: 8%-15%

Details Images

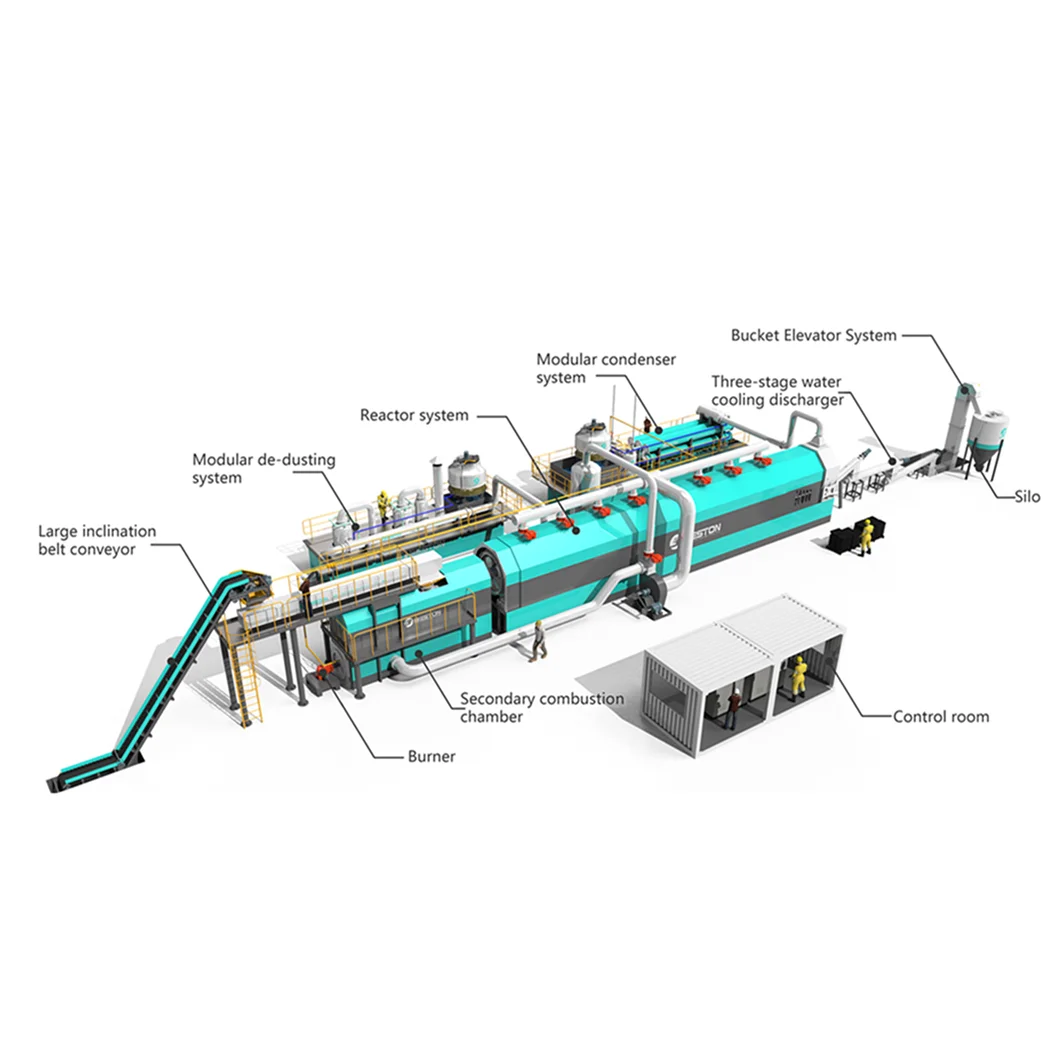

Continuous Pyrolysis Plant Design V.S. Batching Pyrolysis Plant Design

Comparing with the batching type pyrolysis plant, Beston continuous pyrolysis plant design has the following unique features,

■ Faster Feeding and Discharging System

Continuous pyrolysis plant is also called a fully automatic pyrolysis plant because it utilizes automatic screw feeder to feed the raw materials into the reactor. The feeding and discharging happen simultaneously without any interruption in 24 hours a day. As a result, there is no need to wait for the cooling of the reactor before feeding as the batching pyrolysis plants do.

■ Non-rotary Design of A Continuous Pyrolysis Reactor

Batching pyrolysis plant, known as the small scale pyrolysis plant, adopts a rotary reactor. It has a double helix structure inside of the reactor to make sure the raw materials have a 360°rotation while being heated. But the continuous pyrolysis reactor is not rotary. It has a larger space to make sure a large number of raw materials can be heated evenly at the same time.

Note for you: the semi-continuous pyrolysis plant (BLJ-16) adopts the same reactor with the small type plant.

■ Modular Design

Beston fully continuous pyrolysis machine (BLL-30) adopts modular design, which means every part of the equipment can be an independent modular that has high changeability and feasibility.

Usually, a whole set of the plant consists of the following modules, and you can also see the components of Beston pyrolysis plant here.

▷ Feeding System

▷ Heating System

▷ Pyrolysis System

▷ Condensing System

▷ Discharging System

▷ Dedusting System

Thereinto, the continuous pyrolysis plant adopts 3-in-1 discharging system, which combines the condensing system, discharging system as well as the liquefication system together, so as to improve the working efficiency.

Modular design makes the delivery, assembling and maintenance of the plant much more easier, therefore, it has gained a lot of favorable reviews from our customers.

Continuous pyrolysis plant is also called a fully automatic pyrolysis plant because it utilizes automatic screw feeder to feed the raw materials into the reactor. The feeding and discharging happen simultaneously without any interruption in 24 hours a day. As a result, there is no need to wait for the cooling of the reactor before feeding as the batching pyrolysis plants do.

■ Non-rotary Design of A Continuous Pyrolysis Reactor

Batching pyrolysis plant, known as the small scale pyrolysis plant, adopts a rotary reactor. It has a double helix structure inside of the reactor to make sure the raw materials have a 360°rotation while being heated. But the continuous pyrolysis reactor is not rotary. It has a larger space to make sure a large number of raw materials can be heated evenly at the same time.

Note for you: the semi-continuous pyrolysis plant (BLJ-16) adopts the same reactor with the small type plant.

■ Modular Design

Beston fully continuous pyrolysis machine (BLL-30) adopts modular design, which means every part of the equipment can be an independent modular that has high changeability and feasibility.

Usually, a whole set of the plant consists of the following modules, and you can also see the components of Beston pyrolysis plant here.

▷ Feeding System

▷ Heating System

▷ Pyrolysis System

▷ Condensing System

▷ Discharging System

▷ Dedusting System

Thereinto, the continuous pyrolysis plant adopts 3-in-1 discharging system, which combines the condensing system, discharging system as well as the liquefication system together, so as to improve the working efficiency.

Modular design makes the delivery, assembling and maintenance of the plant much more easier, therefore, it has gained a lot of favorable reviews from our customers.

Hydraulic Feed

Reactor

Atomization Tower

Packing for delivery

Installation Instructions

Successful Cases

Beston pyrolysis plant was installed in Paraguay, Chile, Egypt, the Philippines, United Kingdom, South Africa, Hungary,

Indonesia,Romania, Korea, Turkey, Dominica, Uganda, Nigeria, Jordan, Netherlands, Brazil, Canada, Malaysia, Saudi

Arabia,Zimbabwe,etc.

Indonesia,Romania, Korea, Turkey, Dominica, Uganda, Nigeria, Jordan, Netherlands, Brazil, Canada, Malaysia, Saudi

Arabia,Zimbabwe,etc.

About Beston

Beston Group CO.,LTD

Founded in 2013, BESTON GROUP CO., LTD. is a one-stop environmental equipment manufacturing specialist.

Beston has been focus on waste plastic/tyre/rubber recycling, oil sludge treatment, paper recycling, biomass recycling .

Beston has been focus on waste plastic/tyre/rubber recycling, oil sludge treatment, paper recycling, biomass recycling .

Along with the increasingly self-strength and a favorable market environment created by China, Beston Group has developed into a high-tech enterprise with the ability of research, production, sales, services, import and export trading of large waste recycling plants in China nowadays. We promise the quality of all plants we sell to every customer and welcome people from all over the world who have the intention to change the world by waste recycling to contact us.

Why Choose Us

Похожие товары

Электрическая машина для переработки шин

US $850.00

Малая пиролизная установка, небольшая пластиковая пиролизная машина

US $18000-$21000