En1424 1423 AASHTO Тип 0 1 2 3 4 стандартные пескоструйные стеклянные бусины для пескоструйной обработки

- Категория: Abrasives >>>

- Поставщик: Jinan,Junda,Industrial,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 184.93 $* | 188.48 $* |

| Jul-19-2025 | 149.37 $* | 152.53 $* |

| Jun-19-2025 | 181.90 $* | 185.81 $* |

| May-19-2025 | 180.72 $* | 184.14 $* |

| Apr-19-2025 | 144.44 $* | 147.9 $* |

| Mar-19-2025 | 177.7 $* | 181.33 $* |

| Feb-19-2025 | 175.30 $* | 179.4 $* |

| Jan-19-2025 | 174.52 $* | 177.62 $* |

Характеристики

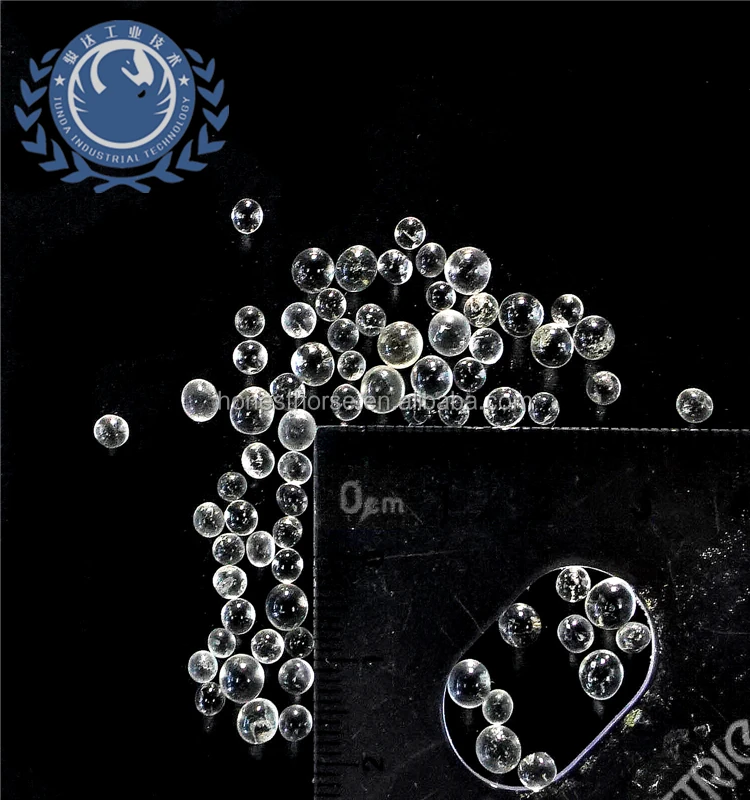

Glass beads for blasting

A GROWING ROLE IN ENSURING HIGHWAY SAFETY

1.With more drivers traveling on more roads, the need to promote safety - especially at night and during poor weather conditions -

has been a continuing concern.

2.In response, HONEST HORSE has developed both materials and technology to improve visibility while enhancing driver safety.

3.Embedding glass beads into highway safety markings creates reflective lines that shine through darkness, rain, and fog to direct

drivers more safely along the road.

4.Customers who rely on our HONEST HORSE products include highway safety authorities, pavement marking material producers, and

road marking companies.

1.With more drivers traveling on more roads, the need to promote safety - especially at night and during poor weather conditions -

has been a continuing concern.

2.In response, HONEST HORSE has developed both materials and technology to improve visibility while enhancing driver safety.

3.Embedding glass beads into highway safety markings creates reflective lines that shine through darkness, rain, and fog to direct

drivers more safely along the road.

4.Customers who rely on our HONEST HORSE products include highway safety authorities, pavement marking material producers, and

road marking companies.

Junda glass bead is a type of abrasive blasting for surface finishing, specifically to prepare metals by smoothing them. Bead blasting provides superior surface cleaning to remove paint, rust and other coatings.

The glass bead blasting process is environment-friendly and chemical-free and can be used to detect weld and solder flaws. Advantages of using glass bead blasting include:

• A large variety of grades available for different jobs and profiles.

• Does not interfere with coatings as it isn't reactive.

• It leaves no residue or embedded contaminants, and also does not cause any dimensional surface change.

• Improved corrosion resistance and the ability to smooth away surface flaws.

• No detectable crystalline silica.

How it works

Junda Glass bead blasting essentially applies fine glass beads of various sizes at varying degrees of pressure. Smaller glass spheres result in a smoother surface while larger spheres produce a more textured finish.

Glass beads do not remove any of the base metal or imbed the surface. It will produce a better, more uniform finish while also adding sheen or brightness to the part.

It has a variety of applications, including:

• Finishing: Can be used on a wide range of materials, including metals, glass, plastic and rubber.

• Cleaning: Without causing a dimensional surface change, glass bead blasting removes/cleans foreign substances.

• Deburring: In order to assemble and operate parts, corners and edges may need to be deburred. Glass bead blasting can remove burrs and feathered edges while ensuring no base metal from the surface is removed.

• Peening: Peening extends the life of metal parts by combating stress cracks and corrosion.

The glass bead blasting process is environment-friendly and chemical-free and can be used to detect weld and solder flaws. Advantages of using glass bead blasting include:

• A large variety of grades available for different jobs and profiles.

• Does not interfere with coatings as it isn't reactive.

• It leaves no residue or embedded contaminants, and also does not cause any dimensional surface change.

• Improved corrosion resistance and the ability to smooth away surface flaws.

• No detectable crystalline silica.

How it works

Junda Glass bead blasting essentially applies fine glass beads of various sizes at varying degrees of pressure. Smaller glass spheres result in a smoother surface while larger spheres produce a more textured finish.

Glass beads do not remove any of the base metal or imbed the surface. It will produce a better, more uniform finish while also adding sheen or brightness to the part.

It has a variety of applications, including:

• Finishing: Can be used on a wide range of materials, including metals, glass, plastic and rubber.

• Cleaning: Without causing a dimensional surface change, glass bead blasting removes/cleans foreign substances.

• Deburring: In order to assemble and operate parts, corners and edges may need to be deburred. Glass bead blasting can remove burrs and feathered edges while ensuring no base metal from the surface is removed.

• Peening: Peening extends the life of metal parts by combating stress cracks and corrosion.

Project | Quality | ||

Chemical composition% | SiO2 | >72% | |

CaO | >8% | ||

Na2O | <14% | ||

MgO | >2.5% | ||

Al2O3 | 0.5-2.0% | ||

Fe2O3 | 0.15% | ||

Others | 2.0% | ||

Refractive Index | Nd≥1.5% | ||

Density | 2.4-2.6g/cm3 | ||

Size distribution | Oversize ≤5% under size ≤10% | ||

Wire diameter | 0.03-0.4mm | ||

Durability | 3-5 % | ||

Hardness | 6-7 MOHS ;46HRC | ||

Microhardness | ≥650kg/cm3 | ||

Circularity | Round rate of ≥95% | ||

Appearance | colorless ,glass transparent without impurities,Round and smooth | ||

Application | 1.Grinding 2.Road marking paint 3.Sand blasting | ||

Lead Content | No lead content, reach American 16CFR 1303 Lead content standard | ||

Harmful substances content | Lower than American 16CFR 1500 standard | ||

Flammable fire test | Not easy combustion,reach American 16CFR 1500.44 standard | ||

Soluble heavy metal content | Metal content of soluble matter ratio solid weight rate no more than ASTM F963 corresponding value | ||

Package | 25KG/pp bag then 40 bags in one ton bag/pallet | ||

Standard | EN1423,1424;AASHTO ,M247;BS6088;JISR3301;KS L2521 ETC. | ||

Glass beads ---- Applications

1.we work with governments around the world to address improvements in highway safety.

2.With our ongoing research into retroreflectivity coupled with our industry leading Technical Service team, our leadership and innovation have set the standards for reflective highway markings.

3.Worldwide acceptance of these safety standards has resulted in global demand for reflective marking materials.

4.Currently, more than two-thirds of our annual worldwide production - the single largest use of our products worldwide - is used for highway delineation and guidance systems.

1.we work with governments around the world to address improvements in highway safety.

2.With our ongoing research into retroreflectivity coupled with our industry leading Technical Service team, our leadership and innovation have set the standards for reflective highway markings.

3.Worldwide acceptance of these safety standards has resulted in global demand for reflective marking materials.

4.Currently, more than two-thirds of our annual worldwide production - the single largest use of our products worldwide - is used for highway delineation and guidance systems.

Packaging&shipping

Our Packages

1.25kg/bag(pp bag or paper bag) then 40 bags in one ton bag/pallet ,

2.one ton one bag

all packages are lined with waterproof materials

We can also pack according to your requirement.

Our Packages

1.25kg/bag(pp bag or paper bag) then 40 bags in one ton bag/pallet ,

2.one ton one bag

all packages are lined with waterproof materials

We can also pack according to your requirement.

Q : What is the mode of payment?

T/T: 50% advance payment then the rest 50% payment pay us when get the scanned B/L from our E-mail

L/C: 100% irrevocable L/C at sight

Q: What’s the MOQ of your products?

As usual, MOQ 5TONS .Or as your require,we need to calculate the new price to you.

Q: Can you provide free samples?

Yes,we can send free samples less than 500g to you.

Q: What standards are you carrying out for your products?

SAE standard and ISO 9001, SGS

T/T: 50% advance payment then the rest 50% payment pay us when get the scanned B/L from our E-mail

L/C: 100% irrevocable L/C at sight

Q: What’s the MOQ of your products?

As usual, MOQ 5TONS .Or as your require,we need to calculate the new price to you.

Q: Can you provide free samples?

Yes,we can send free samples less than 500g to you.

Q: What standards are you carrying out for your products?

SAE standard and ISO 9001, SGS