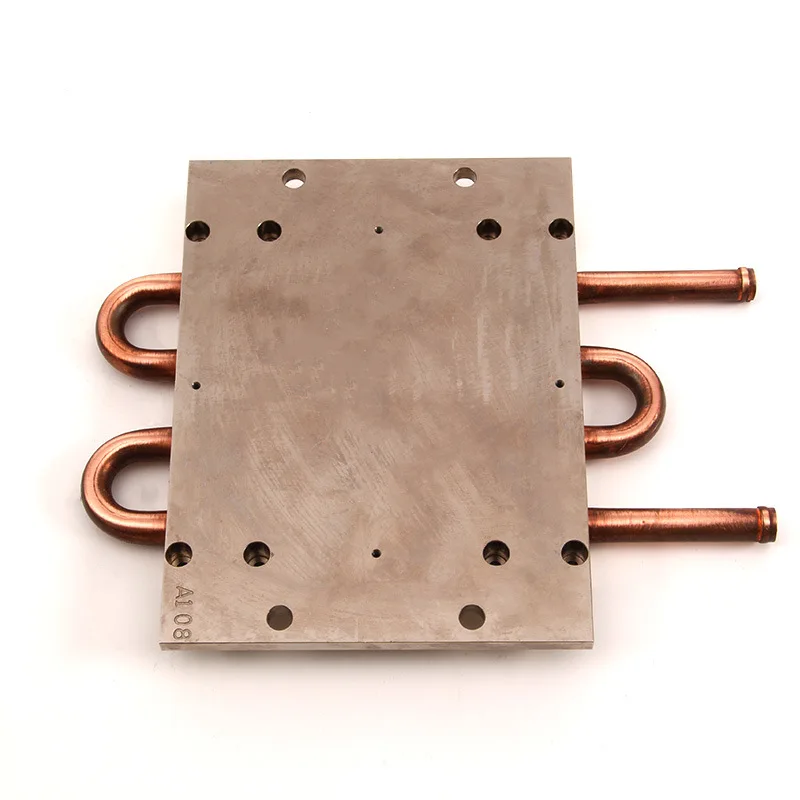

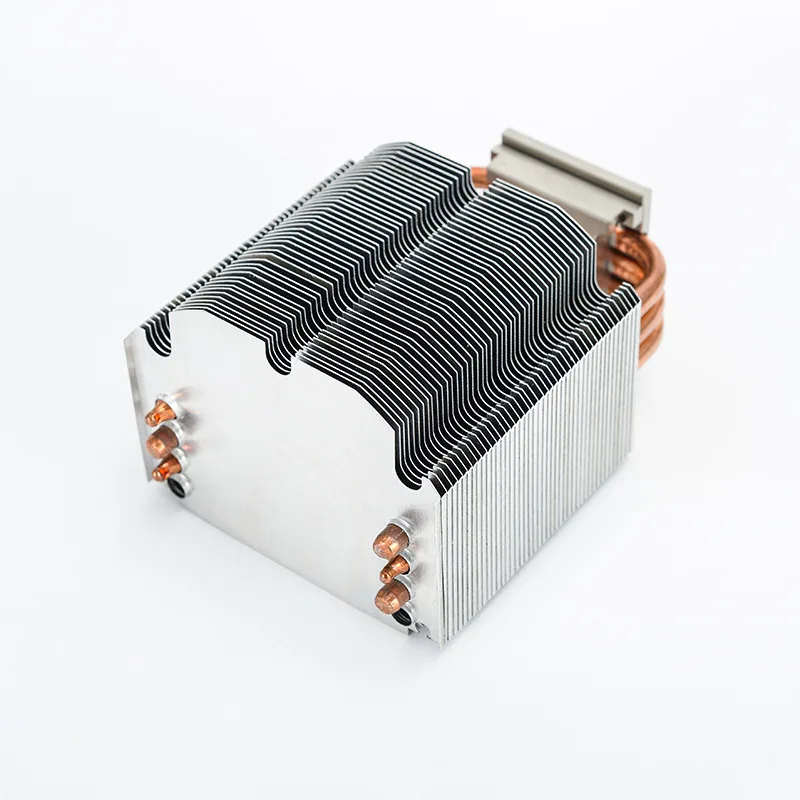

Строительная стальная конструкция Kenli индивидуальный Водяной радиатор алюминиевая жидкая холодная пластина для

- Категория: Steel Structures >>>

- Поставщик: Hebei,Kenli,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 1.20 $* | 1.79 $* |

| Jul-16-2025 | 1.41 $* | 1.68 $* |

| Jun-16-2025 | 1.20 $* | 1.87 $* |

| May-16-2025 | 1.23 $* | 1.11 $* |

| Apr-16-2025 | 1.64 $* | 1.0 $* |

| Mar-16-2025 | 1.6 $* | 1.97 $* |

| Feb-16-2025 | 1.22 $* | 1.5 $* |

| Jan-16-2025 | 1.72 $* | 1.29 $* |

Характеристики

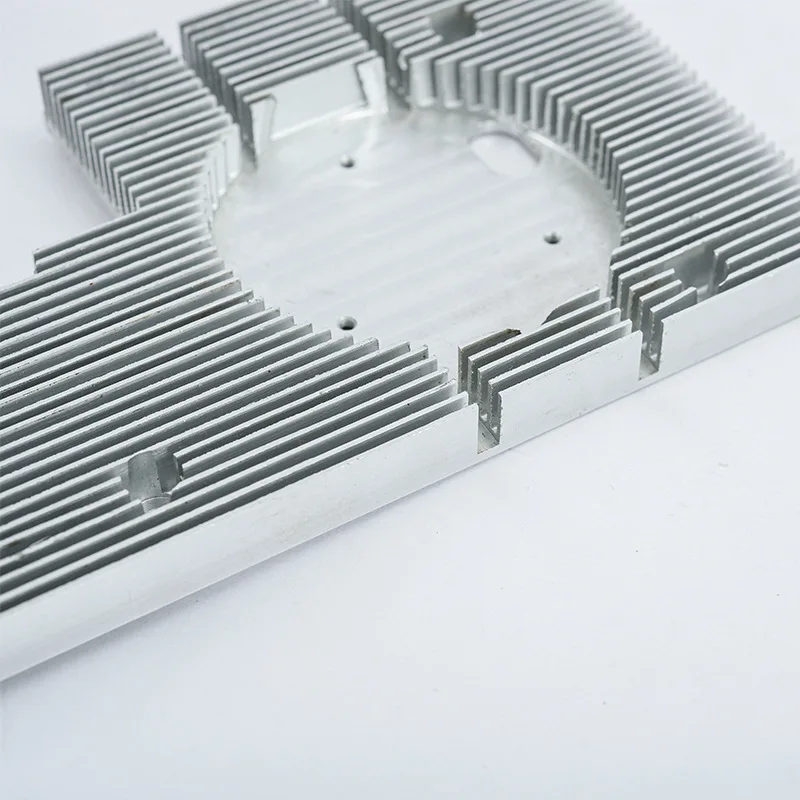

Cooling Plate Aluminum Liquid Cold Plate Liquid Cooler

Specification

Item | Sheet steel stamping |

Material | Carbon Steel, Stainless Steel, Aluminum, Brass, Copper, etc. |

Process | Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding, etc |

Drawing | jpg/.pdf/.dxf/.dwg/.igs./.stp/ etc |

Length | 3-6m. Special length Acceptable |

Machining | CNC,drilling,milling,cutting,welding,bending,assembling |

Test | CMM,Digital Height Gauge, caliper, Coordinate measuring machine, roughness test, hardness test. etc |

Surface Treatment | mill, anodized,powder coated,electrophoresis,wood grain,polish,brushed |

Packing Detail | Inside: packed with plastic film to protect each piece Outside: by waterproof craft paper or EPE film in wooden case |

Production Capacity | 3500 tons monthly, 42000 tons annually. |

MOQ | 500 kgs.Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ |

Delivery | 7-15 days for sample, 30 days for bulk order |

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining

This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials.

Over the history of metal stamping, forging and deep drawing, presses of all types are the backbone of metals manufacturing. The processes continue to improve in moving more metal in one press stroke. Press and interconnected automation devices increase production rates, reduce labor costs and provide more safety for workers.

We Kenli,know how to make complex component parts that meet the most rigid specifications of our customers, and we know how to maintain these specifications through high volume production runs.

* Stainless steel

* Low- and high-carbon steel

* Aluminum

* Titanium

* Brass

* Bronze

* Copper

* Low- and high-carbon steel

* Aluminum

* Titanium

* Brass

* Bronze

* Copper

* Automotive

* Renewable energy

* Medical

* Industrial

* Aerospace

* Hardware

* Home Improvement

* Renewable energy

* Medical

* Industrial

* Aerospace

* Hardware

* Home Improvement

Sheet metal stamping: the types of processes

* Metal blanking: sheet blanking on iron, aluminum, copper, brass and special alloys is carried out with punching and matrixes.

* Sheet metal deep-drawing: which can turn flat metal sheets transforming them into metal components such as cylinders,hemispherical caps, or finished products such as pots and pans or other kinds of containers.

* Sheet metal bending: used to obtain semi-finished products through the pressure exerted by the mold during the metal working.

* Sheet metal deep-drawing: which can turn flat metal sheets transforming them into metal components such as cylinders,hemispherical caps, or finished products such as pots and pans or other kinds of containers.

* Sheet metal bending: used to obtain semi-finished products through the pressure exerted by the mold during the metal working.

* Sheet metal punching: achieved by using automatic CNC machines and standard or special punches and tools, is performed on iron,stainless steel, aluminum, copper, brass and special alloys.

* Metal threading: used to fix together two or more metal parts.

* Metal threading: used to fix together two or more metal parts.

Not sure what to get? Consult our sales team for assistance!

Packing & Delivery

(Protective Tape+Shrink film+waterproof kraft paper+wooden case) To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Quality Control

Professional measure tools at every aspect size,testing hardness,surface film,physical property,loading weight etc

Company Profile

Hebei Kenli Technology Co.,Ltd ,which covers an orea of 180,000 square meters,total construction area of production,office is 80,000 square meters,equipped with 12 domestic most advanced aluminum production lines, the annual production capacity of 32,000 tons in Hebei Province.With innovative mold design,aluminum alloy extrusion, oxidation coloring, electrophoretic spraying, home decoration,curtainwall ond broken bridge insulation produetion copacity.

We always focuse on the research and development of forward looking marketand high-tech content of new products. In strict accordance with GB/T5237-2017,GB/T6892-2015 standard production,and exporied to the United States. Europe,South Korea and southeost Asian countries.

Upholdthe sincere friendship, win-win cooperation'construction of "heart,concentration and satisfaction",we are willing to work with you to forge ahead in the new area, create a quality future!

We always focuse on the research and development of forward looking marketand high-tech content of new products. In strict accordance with GB/T5237-2017,GB/T6892-2015 standard production,and exporied to the United States. Europe,South Korea and southeost Asian countries.

Upholdthe sincere friendship, win-win cooperation'construction of "heart,concentration and satisfaction",we are willing to work with you to forge ahead in the new area, create a quality future!

SURFACE TREATMENT

Aim:high corrosion resistance,weather resistance and good wear resistance

Anodizing

Different Color Anodizing

film 10-25um

Powder Coating

high coating hardness and strong adhension

15years+ useful life

Electrophoresis

smooth and colorful surface

Wooden Grain Transfer

New generation decorative material which produces a natural apperance

Brushing(Noble and elegant)

brushed lines are very neat

Polishing

see no any mechanical line

The reason why aluminium extrusion can be widely used

one is that aluminium extrusion has a variety of surface colours. Anodising and powder coating are familiar to us, but there are some maybe we don’t know.

Focus us and you’ll know more.

FAQ

Q: Do you make extrusion profile different sizes?

A: Yes.Many sizes are stock.5days mill finishing,10days anodizing/powder coating

Q: Can you make holes?

A: Yes,different holes acceptable.

Q: What is different surface thickness?

A:Anodized:7-23 μm, Powder coating: 60-120 μm , Electrophoresis film: 12-25 μm

Q:What is MOQ?

A: 500KGS.Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for many years.

Q: Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time.Honesty is our company's tenet.

Q: Do you provide samples ? is it free or extra ?

A: The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q: How could you guarantee your products?

A: Each piece of products is manufactured by certified workshops, inspected by piece by piece according to

inational QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

Q: How can I get your quotation as soon as possible?

A: The email will be checked within one hours,meanwhile,the Skype,Wechat and WhatsApp

will be online in 24 hours.Please send us your requirement , we will work out a best price soon.

Q: Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time.Honesty is our company's tenet.

Q: Do you provide samples ? is it free or extra ?

A: The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q: How could you guarantee your products?

A: Each piece of products is manufactured by certified workshops, inspected by piece by piece according to

inational QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

Q: How can I get your quotation as soon as possible?

A: The email will be checked within one hours,meanwhile,the Skype,Wechat and WhatsApp

will be online in 24 hours.Please send us your requirement , we will work out a best price soon.