Экономичный листогибочный станок

- Категория: Industrial Machinery >>>

- Поставщик: Maanshan,Genuo,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 10829.78 $* | 11370.97 $* |

| Aug-17-2025 | 10738.58 $* | 11275.49 $* |

| Jul-17-2025 | 9009.7 $* | 9459.83 $* |

| Jun-17-2025 | 10556.32 $* | 11084.76 $* |

| May-17-2025 | 9191.3 $* | 9651.43 $* |

| Apr-17-2025 | 10374.13 $* | 10893.96 $* |

| Mar-17-2025 | 10283.6 $* | 10797.16 $* |

| Feb-17-2025 | 10192.62 $* | 10702.36 $* |

| Jan-17-2025 | 10101.52 $* | 10606.48 $* |

Характеристики

Products Description

Machine Feature

GENUO Genius HSC series CNC press brake adopts integral processing and tempering

ultra-high strength frame. The CNC control system can independently and accurately

control Y1 and Y2 axes to make the ram run synchronously.The advanced servo

proportional valve ensures high bending accuracy and stability through real-time

feedback of grating ruler. Large stroke and daylight combined with multi axis optional

high-precision back guiding rule system can realize more flexible bending size and

angle.

The multi-functional CNC control can automatically calculate the pressure, crowning

and unfolding size according to the length and thickness of the workpiece.

There are also 2D and 3D image editing and demonstration options to make bending

easier and more efficient. This is the most mainstream and popular cost-effective

CNC press brake in the market. 40T ~ 800T optional.

Standard Equipment | Optional Equipment | ||||||||

◆CYBELEC CybTouch 12 CNC Control | ◇Delem DA-58T,ESA S640,DA-66T,ETC-16T | ||||||||

◆Mono block welded rigid to deflection and high tensile steel frame | ◇2 axis back gauge with R-axis or mutil-axis | ||||||||

◆High precision Y1,Y2 axis synchronized closed-loop feedback | ◇Z1,Z2 Joy stick control back gauge fingers | ||||||||

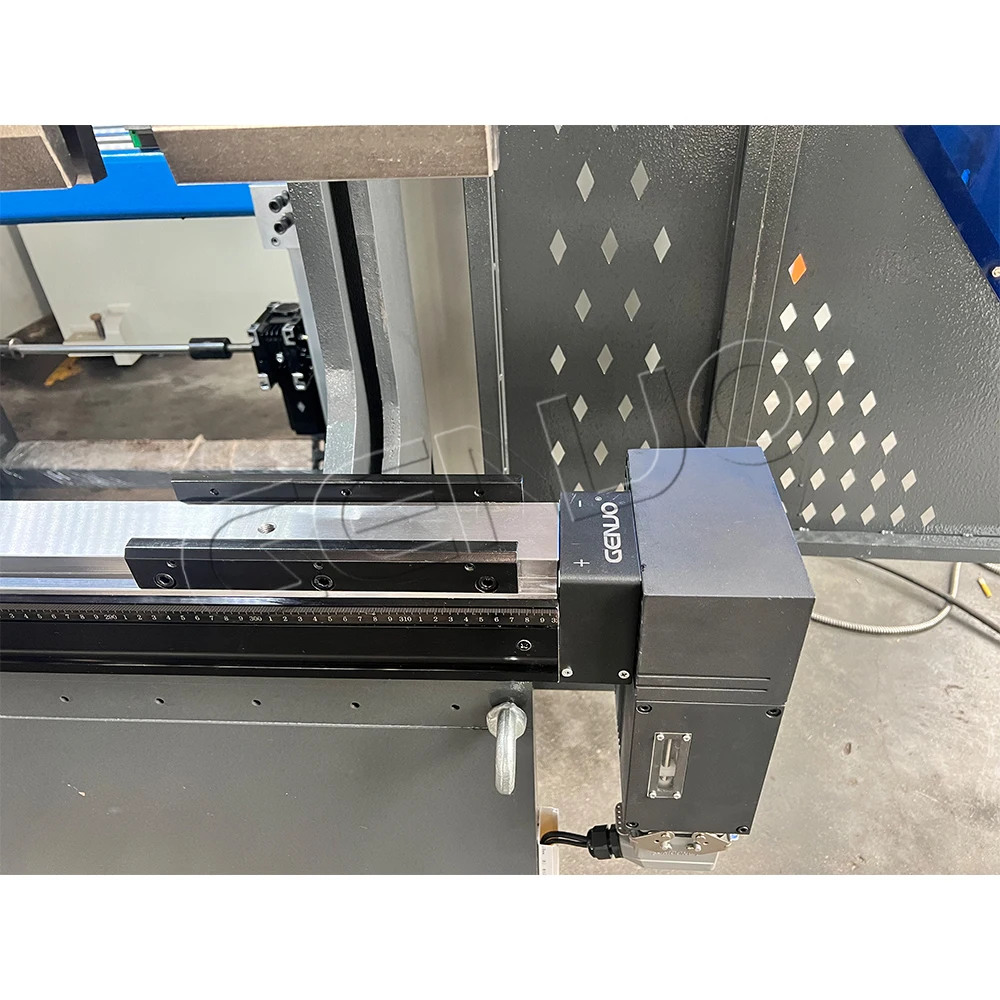

◆Accurate heavy-duty X axis back gauge system | ◇DSP or SDKELI Laser front guard options | ||||||||

◆Auto Motorized crowning system/Hydraulic cylinder crwoning | ◇Energy saving and low noise main servo motor drive | ||||||||

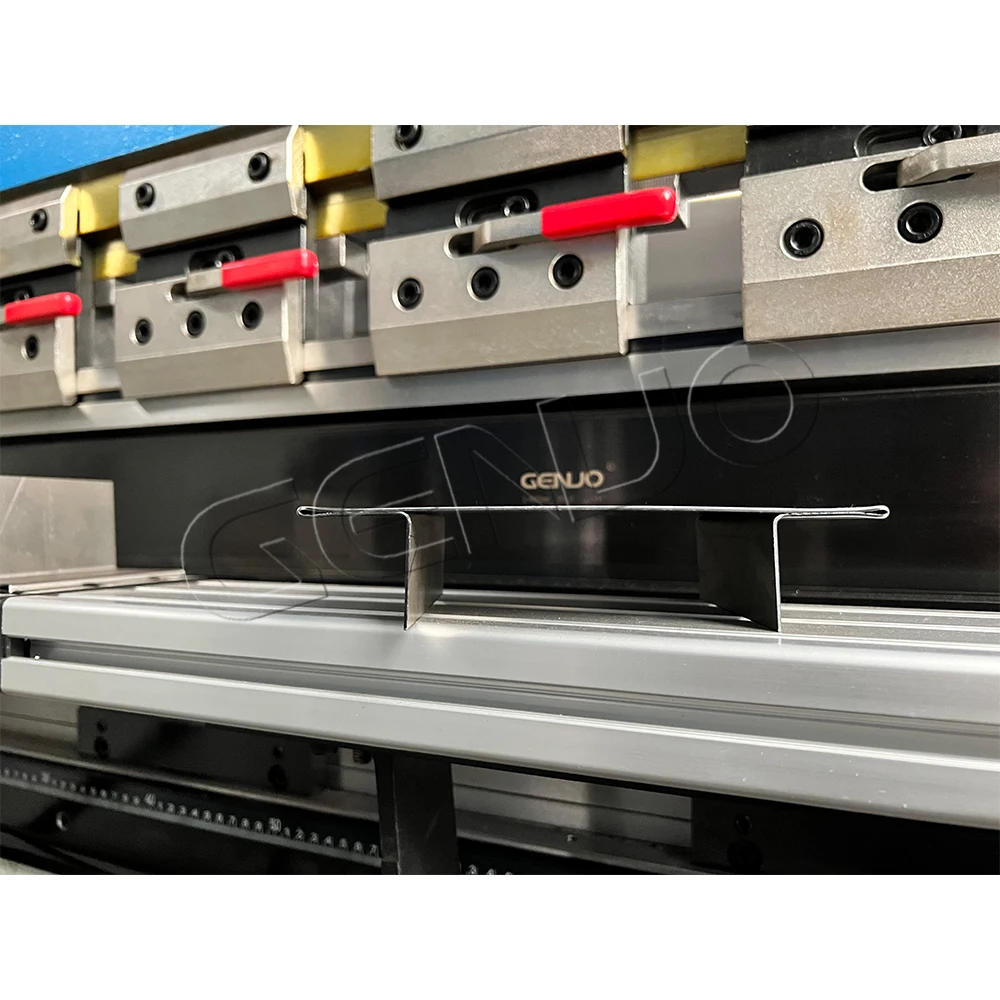

◆European-style punch and 4V/2V/1V Dies | ◇WILA type top and bottom tool clamping system | ||||||||

◆Fast punch clamps and movable sliding front support | ◇Bending tools management cabinet or trolley | ||||||||

◆BOSCH Rexroth hydraulic system,GIVI linear encoder | ◇Special heights, Daylight, Throat Depth are available | ||||||||

◆SIEMENS main motor,Sunny pump,Schneider Electric | ◇40~800 Tons and 4~20ft Bending Lengths options | ||||||||

◆EMB ferrule type pipe connector, NOK sealing rings | ◇Single/Tandem/Trio optional | ||||||||

High precision closed loop CNC control

▼Rigid Frame Construction

GENUO have vast experience with

R&D and designing components to

very tight tolerances for machine

frames. So for complicated

structures, highly complex

structures, highly complex

loadings and transient modelling.

The foundation of all GENUO press

brakes is a solid,monoblock frame

made from high-yield steel.

made from high-yield steel.

▼Proportional Control

German Bosch Rexroth integrated

"hydraulic system block",

hydraulic transmission with high

reliability , integrated hydraulic

system can effectively alleviate

"hydraulic system block",

hydraulic transmission with high

reliability , integrated hydraulic

system can effectively alleviate

the problem caused by leakage

of hydraulic fluid.

▼Linear Encoder Feedback

The deformation is measured

accurately and compensated

by feedback method.

The accuracy can be achieved

uM level.

Establishing the right back gauge for your projects will allow for increased part production

and precision.From intricate parts which typically require more axes to large quantities

that require more time and therefore increased cost, the correct back gauge for each

job is essential to lowering costs per part which ultimately benefts your bottom line.

GENUO technicians are happy to assist you with any questions you may have on your

project requirements.

To confrm a constant bend angle, manual or CNC crowning is essential which will offset

potential deviations and allow for possible tooling wear to maintain parallel contacting

surfaces.CNC crowning systems allow the press brake control to be pre-programmed

with machine characteristics and defection data.

Adjust the calculate and setting accordingly for different characteristics of different

materials.

GENUO provides a variety of tooling solutions to meet your different production needs.

Not only that, we are also experts in the field of bending tools. If you have any special

bend, our engineers will customize special tools for each workpiece, which greatly

expands your press brake function and revenue.

To help greatly improve your productivity and business benefits.

▼Stable Electrical Cabinet

Durable France Schneider electrics

ensure the stableoperation of the

machine.Reasonable line

connection and arrangement

greatly reduces the failure rate.

The integrated control module of

The integrated control module of

hydraulic valve group makes the

sliding block move smoothly and

accurately. And the operator and

all parts of the machine played a

good protection.

▼Superior Hydraulic System

Integrated Rexroth hydraulic system,

quick response. The low failure rate

makes the machine run safely,

efficiently and stably.The whole

series of standard is equipped with

galvanized cold drawn pipe and

galvanized cold drawn pipe and

German EMB ferrule type pipe joint.

Reduce the risk of oil leakage by

50% compared with rubber and

welded seamless tubing.

And in can be longer service life.

▼Low Noise and Powerful Force

Using Germany Siemens main motor and USA SUNNY or FIRST gear oil

pump guarantee the machine service life and improve the machine working stability.

Reasonable matching makes the machine burst out strong and lasting pressure.At the same time, the

Reasonable matching makes the machine burst out strong and lasting pressure.At the same time, the

special coupling device also greatly reduces the noise of the machine in

the process of running.

DSP LASER protects the press brake

operator from the danger of crushing

that can take place accidentally

between the moving part of the

machine and the fixed one.

It assures to carry out the machine

working cycle penalizing its execution

time in the least.

WILA'S state of the art Clamping

systems can offer the ultimate

solution when it comes to efficiently

changing tools both hydraulical and

Pneumatic.

Accuracy and ergonomics have been

coordinated to realize the highest

level of productivity.

This CNC bending support suitable

for all kinds of large sheet metal,

especially thin metal sheet.Perfect to

maintain synchronization with the

sheet during the bending process.

which lightens the operators work

moving heavy pieces, improves

bending efficiency and reduces

operator risk.

Product Paramenters

Model | Nominal Pressure (kn) | Bending Length (mm) | Columns Distance (mm) | Ram Strokes(mm) | Throat Death (mm) | Open Height (mm) | Motor Power (kw) | Dimension (L x W x H) (m) | ||||||||

HTC PTO | / | A | B | C | D | E | / | / | ||||||||

40T1600 | 400 | 1600 | 1250 | 150 | 300 | 420 | 4 | 2.0*1.8*2.4 | ||||||||

63T2500 | 630 | 2500 | 1960 | 150 | 320 | 420 | 5.5 | 2.9*1.8*2.4 | ||||||||

100T3200 | 1000 | 3200 | 2600 | 200 | 400 | 480 | 7.5 | 3.9*1.9*2.6 | ||||||||

100T4000 | 1000 | 4000 | 3200 | 200 | 400 | 480 | 7.5 | 4.6*1.9*2.7 | ||||||||

125T3200 | 1250 | 3200 | 2600 | 200 | 400 | 480 | 11 | 3.9*1.9*2.6 | ||||||||

160T3200 | 1600 | 3200 | 2600 | 200 | 400 | 480 | 11 | 3.9*1.9*2.6 | ||||||||

200T3200 | 2000 | 3200 | 2600 | 200 | 400 | 480 | 15 | 3.9*1.9*2.7 | ||||||||

320T4000 | 3200 | 4000 | 3200 | 200 | 400 | 480 | 22 | 4.8*2.1*3.2 | ||||||||

500T6000 | 5000 | 6000 | 4900 | 320 | 500 | 600 | 37 | 6.5*2.8*4.5 | ||||||||

The above data is only for reference only,to prevail in kind. More specifications available. Please click here! | ||||||||||||||||

Recommend Products

Company Profile

FAQ

Q1: Are you manufacturer or trading company ?

A2: We are factory with more than 20 years of technology and experience.

Q2: How long is your delivery time ?

A2: General speaking, if the machines is in stock, we can delivery them with 3-7 days, If the quantity is 1-2 container, we can give you with 25-35 days,if the quantity is more than 2 container and you are very urgent, we can let factory priority produce your goods.

Q3: Do you provide samples ? Is it free or extra ?

A3: For new customer, We can provide charge samples for standard fastener. For old customer,We will send you free samples But the clients will pay the express charges.

Q4: What is your terms of payment ?

A4: We can accept T/T,LC for general order ,Paypal and Western union for small order or samples order. Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q5. How about your machine quality?

A2: We are factory with more than 20 years of technology and experience.

Q2: How long is your delivery time ?

A2: General speaking, if the machines is in stock, we can delivery them with 3-7 days, If the quantity is 1-2 container, we can give you with 25-35 days,if the quantity is more than 2 container and you are very urgent, we can let factory priority produce your goods.

Q3: Do you provide samples ? Is it free or extra ?

A3: For new customer, We can provide charge samples for standard fastener. For old customer,We will send you free samples But the clients will pay the express charges.

Q4: What is your terms of payment ?

A4: We can accept T/T,LC for general order ,Paypal and Western union for small order or samples order. Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q5. How about your machine quality?

A5:Our machines distribute worldwide to about 50 counties where there are metal plate ind ustry ,there are Brilliant machines And where there are our machines,there are good reputation and terminal user satisfaction.

Q6.How about your after-sale service?

A6:1.Technical solutions: we can provide technical solutions within one day.

2.Online video: Show you machine working video in factory.( update every week)

3.Installation service: This is available with all of our machines,live video can be provided. We can also dispatch technician to customer's factory for installation machines.

Q6.How about your after-sale service?

A6:1.Technical solutions: we can provide technical solutions within one day.

2.Online video: Show you machine working video in factory.( update every week)

3.Installation service: This is available with all of our machines,live video can be provided. We can also dispatch technician to customer's factory for installation machines.

(Customers only need to pay for the airfare and hotel expense.)

4.Training service: Our technician will teach you how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5.Quality guarantee: 2 years warranty, we provide lifetime service. We arrange final test before shipment, After making sure machine is the best performance, then make shipments.

6.100% response rate: we will reply your questions within 12 hours.

4.Training service: Our technician will teach you how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5.Quality guarantee: 2 years warranty, we provide lifetime service. We arrange final test before shipment, After making sure machine is the best performance, then make shipments.

6.100% response rate: we will reply your questions within 12 hours.

Contact us