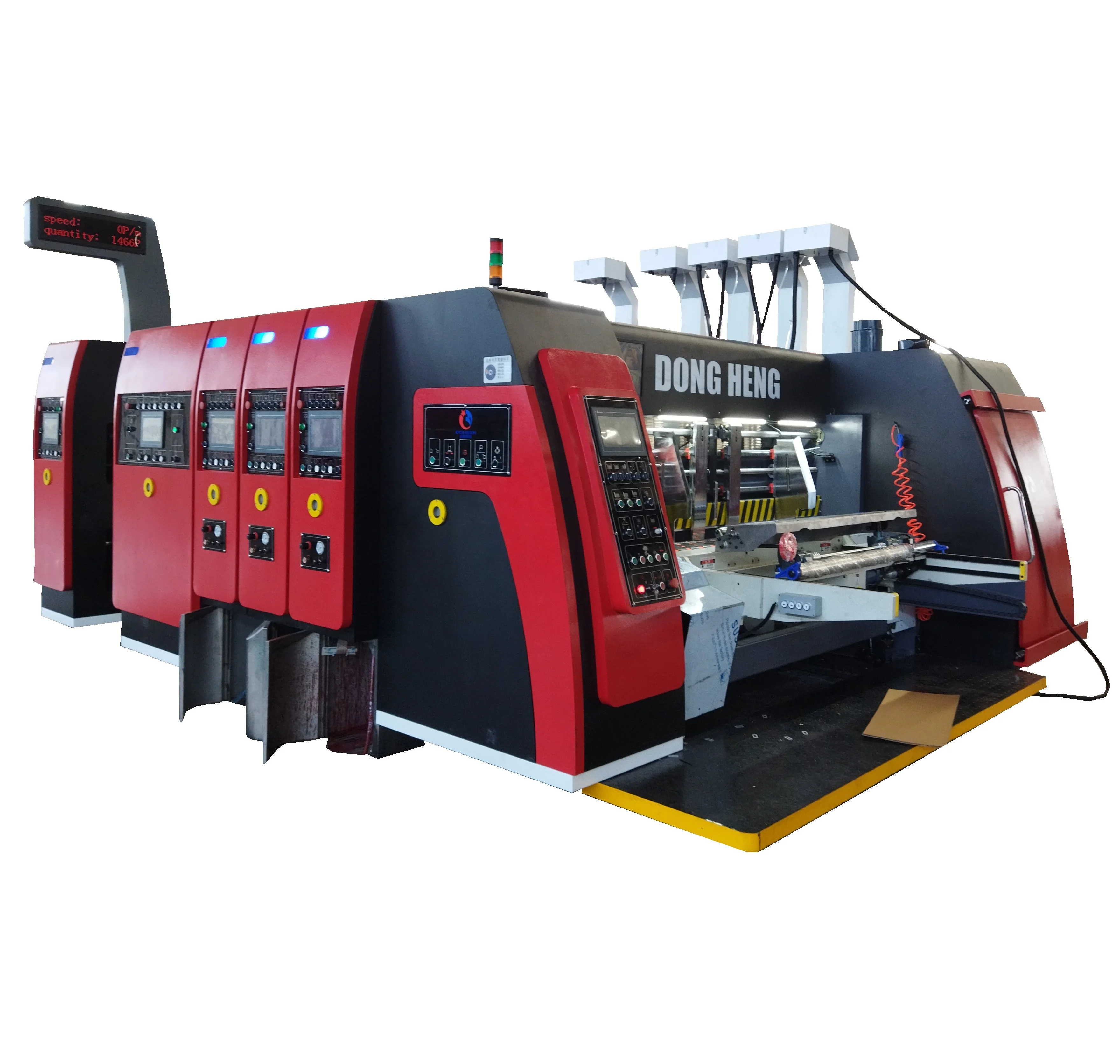

Гофрированный картон Крышкоделательная машина линия гофрированного картона печати долбежные высечки

- Категория: >>>

- Поставщик: Hebei,Dongheng,Packaging,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 67235.10 $* | 70597.66 $* |

| Aug-16-2025 | 66670.19 $* | 70004.45 $* |

| Jul-16-2025 | 55935.30 $* | 58732.49 $* |

| Jun-16-2025 | 65540.97 $* | 68817.29 $* |

| May-16-2025 | 57065.14 $* | 59918.45 $* |

| Apr-16-2025 | 64410.59 $* | 67631.19 $* |

| Mar-16-2025 | 63845.12 $* | 67037.4 $* |

| Feb-16-2025 | 63280.16 $* | 66444.6 $* |

| Jan-16-2025 | 62715.53 $* | 65851.12 $* |

Характеристики

Products Description

High Speed Automatic Corrugated Carton Printer Slotter Die Cutter Machines

(XTREM SERIES: DHY-SX920, DHY-SX1224, DHY-SX1624, DHY-SX1828, DHY-SX2536)

1. Open & close type units combination.

2. High humanization request design, can accomplish the order setting, changing, production in short time, and display

the current work details.

3. 7 inch colorful touch screen can 7 inch colorful touch screen can input, check, revise, and save production orders.

4.Advanced vacuum absorb lead edge automatic feeding system.

5. All drive rollers are made of high quality steel, surface hard chrome plating and lapping treated. The drive gears are

made of high quality alloy steel, surface hard chrome plating and lapping treated. All main gears are auto lubricated with

oil, increase the service life of the gears.

6. All assembling accessories are tempering treated to be more solid durable. All these accessories are made by

high-precision processing center and grinded by numeric-control grinder.

7. Roller gaps are adjusted by high precise worm box with a range of 0-11mm, 3 three-head handles are equipped for

your easier adjustment.

8. Self-locking device to lock the machine when it's working. For security, the machine cannot start without locking the

machine units.

9. auto-zero device ensuring uniform adjustment of the machine.

(XTREM SERIES: DHY-SX920, DHY-SX1224, DHY-SX1624, DHY-SX1828, DHY-SX2536)

1. Open & close type units combination.

2. High humanization request design, can accomplish the order setting, changing, production in short time, and display

the current work details.

3. 7 inch colorful touch screen can 7 inch colorful touch screen can input, check, revise, and save production orders.

4.Advanced vacuum absorb lead edge automatic feeding system.

5. All drive rollers are made of high quality steel, surface hard chrome plating and lapping treated. The drive gears are

made of high quality alloy steel, surface hard chrome plating and lapping treated. All main gears are auto lubricated with

oil, increase the service life of the gears.

6. All assembling accessories are tempering treated to be more solid durable. All these accessories are made by

high-precision processing center and grinded by numeric-control grinder.

7. Roller gaps are adjusted by high precise worm box with a range of 0-11mm, 3 three-head handles are equipped for

your easier adjustment.

8. Self-locking device to lock the machine when it's working. For security, the machine cannot start without locking the

machine units.

9. auto-zero device ensuring uniform adjustment of the machine.

ORIGINAL DESIGN

MACHINE CONFIGURATION

FEEDING UNIT

Details -Feeding Unit

1. Advanced lead edge feeding system, high speed and high accuracy automatic feeding.

2. The space of the feeding area is adjustable.

Left, right and rear guards are motorized moved.

The two front guards height are manually and synchronously lifting up and down, this is for feeding cardboards of

different thicknesses.

Pneumatic flapping device on the right side guard.

3. Both continuous feeding and skip feeding are available.

4. High quality rubber rollers in the feeding unit for high speed and high precision feeding.

5. Both brush device and wind blower for dust removal.

6. 7 inch colorful touch screen, can acheive below operations:

1. Advanced lead edge feeding system, high speed and high accuracy automatic feeding.

2. The space of the feeding area is adjustable.

Left, right and rear guards are motorized moved.

The two front guards height are manually and synchronously lifting up and down, this is for feeding cardboards of

different thicknesses.

Pneumatic flapping device on the right side guard.

3. Both continuous feeding and skip feeding are available.

4. High quality rubber rollers in the feeding unit for high speed and high precision feeding.

5. Both brush device and wind blower for dust removal.

6. 7 inch colorful touch screen, can acheive below operations:

Input, check, revise, and save production order details.

Save volume can be 200 orders.

Automatic and manual setting job dimensions.

The whole machine sychronously go back to zero

Control the open and close of the printing roller and the press roller

Save volume can be 200 orders.

Automatic and manual setting job dimensions.

The whole machine sychronously go back to zero

Control the open and close of the printing roller and the press roller

PRINTING UNIT

1. Printing setting adopts electrical digital adjusting at 360 degree. (Both stop and start)

2. Ratchet type fixed scroll bar for printing plate mounting quickly. The scroll bar with locking up device at the left and

right side to secure the printing precision.

Scale marks on the plate cylinder for easier plate mounting.

Foot switch control the running direction of roller for easier printing plate changing.

3. Auto-zero device supplies uniform adjust line for every unit.

4. Anilox roller equipped with automtic pneumatic lifting system and automatic idling system.

Anilox roller contact with the plate roller when feeding starts.

Anilox roller separate with the plate roller when feeding stops.

The anilox roller start idling when machine printing stops.

5. The printing roller made of high quality steel with surface grinded and hard chromed. Balance aligned for high speed

smooth running.

6 The gear adopts non-backlash adjustment mechanism

2. Ratchet type fixed scroll bar for printing plate mounting quickly. The scroll bar with locking up device at the left and

right side to secure the printing precision.

Scale marks on the plate cylinder for easier plate mounting.

Foot switch control the running direction of roller for easier printing plate changing.

3. Auto-zero device supplies uniform adjust line for every unit.

4. Anilox roller equipped with automtic pneumatic lifting system and automatic idling system.

Anilox roller contact with the plate roller when feeding starts.

Anilox roller separate with the plate roller when feeding stops.

The anilox roller start idling when machine printing stops.

5. The printing roller made of high quality steel with surface grinded and hard chromed. Balance aligned for high speed

smooth running.

6 The gear adopts non-backlash adjustment mechanism

COMPUTER SLOTTING UNIT

1. Slotting setting applies PLC touch screen and electrical digits with 360 degree (both stop and start). Automatic

adjustment and automatic registration.

2. 5 sets of knives for slotting, corner cutting and edge cutting.

Both computer adjustment and electrical motorized adjustment available for the carton height and the horizontal

and vertical movement of the knives.

3. Slotting knives, creasing wheels and pre-pressing wheels united moved.

Top slotting knives fixed into bottom knife grooves, move together as one single unit.

4. The roller gaps adjustment adopts high precision worm box, worm gear self-locking. Equipped with 3 three-head

handle for instant and easy handling, gap ranges 0-11mm.

5. Planetary gear running structure achieve longer service life.

6. Single axle with double knives as slotting structure, carton height adjusted by inner gear system which prevent the carton polluted caused by lubricating oil. Anti-collision protection system to protect the machine accessories when

adjust the carton height.

7. Unique spring type scraps removing device

adjustment and automatic registration.

2. 5 sets of knives for slotting, corner cutting and edge cutting.

Both computer adjustment and electrical motorized adjustment available for the carton height and the horizontal

and vertical movement of the knives.

3. Slotting knives, creasing wheels and pre-pressing wheels united moved.

Top slotting knives fixed into bottom knife grooves, move together as one single unit.

4. The roller gaps adjustment adopts high precision worm box, worm gear self-locking. Equipped with 3 three-head

handle for instant and easy handling, gap ranges 0-11mm.

5. Planetary gear running structure achieve longer service life.

6. Single axle with double knives as slotting structure, carton height adjusted by inner gear system which prevent the carton polluted caused by lubricating oil. Anti-collision protection system to protect the machine accessories when

adjust the carton height.

7. Unique spring type scraps removing device

DIE CUTTING UNIT

1. 4.Die cutting setting adopts PLC and electric digital adjustment with 360 degree ( both stop and start)

2. Rubber cushion roller has cutting and repair mechanism. The rubber dressing can be used repeatedly.

3. A speed difference-off setting device is adopted that can automatically adjust the rotation speed of the rubber roller so that the die cutting carton has exactly the same shape as the die shape

4. Axially conjunct moving of the cam type soft roller is 40mm, uniform wear and tear raises the occupation of the gum cover, save the cost.

5. The feeder roller has 4 feeding wheels, they are dynamic balancing adjusted with stable operation. The surface is grinded and hard chromed.

6. Feeding rollers gap is adjusted by high precise worm box with a range of 0-11mm.

2. Rubber cushion roller has cutting and repair mechanism. The rubber dressing can be used repeatedly.

3. A speed difference-off setting device is adopted that can automatically adjust the rotation speed of the rubber roller so that the die cutting carton has exactly the same shape as the die shape

4. Axially conjunct moving of the cam type soft roller is 40mm, uniform wear and tear raises the occupation of the gum cover, save the cost.

5. The feeder roller has 4 feeding wheels, they are dynamic balancing adjusted with stable operation. The surface is grinded and hard chromed.

6. Feeding rollers gap is adjusted by high precise worm box with a range of 0-11mm.

Marketing Campaign

The DHY-SX series can be upgraded to be full computer control.

With the full computer system, you need only to input all measure data into the computer, and press "start" to finish all setting.

DHY-SX with full computer control

DHY-SX with full computer control

Product Paramenters

Below are the standard dimensions for our machine. We can also customize the machine according to your requests.

Please feel free to contact our sales if there is a need.

Please feel free to contact our sales if there is a need.

Specification | DHY-SX920 | DHY-SX1224 | DHY-SX1624 | DHY-SX1828 | DHY-SX2536 |

Speed(Pcs/Min.) | 240 | 200 | 160 | 140 | 80 |

Max. Sheet (Continous Feeding) | 900X2050 | 1200X2450 | 1600X2450 | 1800X2850 | 2500X3650 |

Max.Sheet (Skip Feeding) (mm) | 1100X2050 | 1500X2450 | 2000X2450 | 2200X2850 | 2900X3650 |

Min. Sheet (mm) | 280X630 | 350X690 | 420X730 | 450X750 | 650X900 |

Max. Printing (mm) | 840X2000 | 1160X2400 | 1550X2400 | 1750X2800 | 2500X3600 |

Printing Plate Thickness (mm) | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

Printing Precision (mm) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

Cardboard Thickness(mm) | 1.5-11 | 1.5-11 | 1.5-11 | 1.5-11 | 1.5-11 |

Customer Photos

Certifications

All of our machines are covered with CE certificate.

The workmanship quality, installation standard can all meet the EU regulations.

There is no problem for you to import, use and resell in European countries.

The workmanship quality, installation standard can all meet the EU regulations.

There is no problem for you to import, use and resell in European countries.

Service

PRE-SALE SERVICE

* Prompt response and quotation

* Professional and positive purchase suggestion

* Factory visit

* Professional and positive purchase suggestion

* Factory visit

AFTER-SALE SERVICE

* Training how to use the machine.

* Engineers available to work overseas.

* Technical support for the whole using life.

* Engineers available to work overseas.

* Technical support for the whole using life.

Our Advantages

1. We have more than 20 years manufacturing experience.

2. We have mature research and development team to design the best machine for the market.

3. We have experienced workers which have been working us from the beginning.

4. We have high precision CNC machines for our accessories machining.

5. We use all high quality accessories and components our machine.

6. We prepare sufficient accessories for our future orders to be finished in short time.