Больничная фабрика машина для производства нетканых рукавов со стабильной

- Категория: Nonwoven Machines >>>

- Поставщик: Chipbest,Technology,(Dongguan),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 47600.11 $* | 49980.64 $* |

| Aug-15-2025 | 47200.15 $* | 49560.68 $* |

| Jul-15-2025 | 39600.96 $* | 41580.87 $* |

| Jun-15-2025 | 46400.18 $* | 48720.53 $* |

| May-15-2025 | 40400.38 $* | 42420.96 $* |

| Apr-15-2025 | 45600.69 $* | 47880.43 $* |

| Mar-15-2025 | 45200.88 $* | 47460.94 $* |

| Feb-15-2025 | 44800.0 $* | 47040.79 $* |

| Jan-15-2025 | 44400.69 $* | 46620.30 $* |

Характеристики

Hospital Factory Work Stable Speed Non woven Fabric Sleeve Making Machine Arm Cover Oversleeves Cuff Arm Sleeve Making Machine

Introduction :

The nonwoven sleeve making machine is just to produce the medical long sleeve, after sleeve finished, can use the gown making machine to make the gown body, and then use sewing machine to the sew the sleeve and gown body, the final products can be the whole medical gown cloth for hospital doctor.

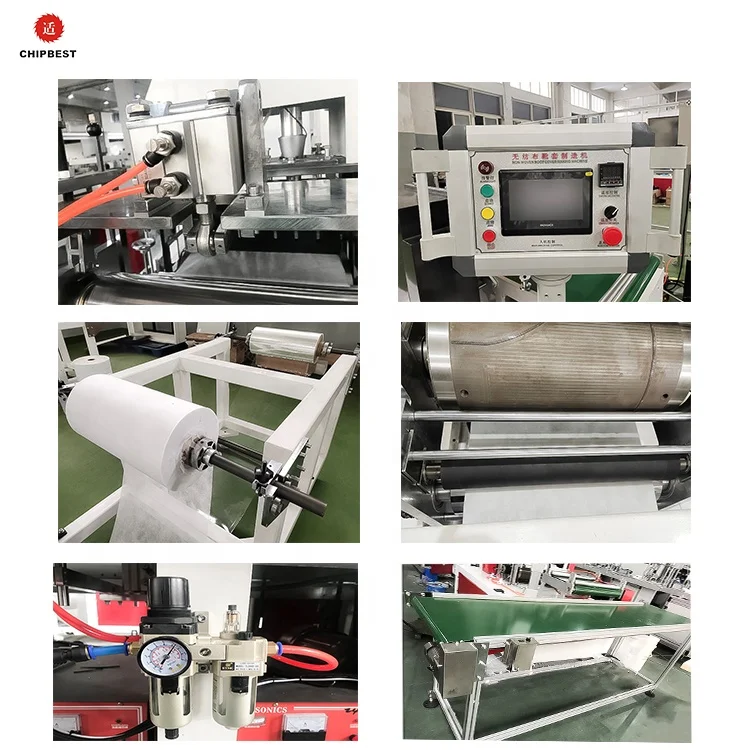

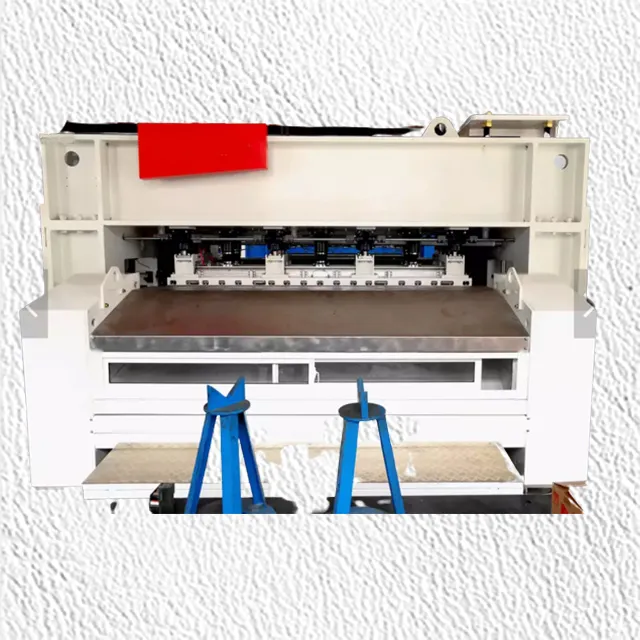

Nonwoven Sleeve Making Machine Photo :

Machine Parameters:

Model Name | JS-SM Gown Sleeve Making Machine |

Machine Size | 5000×2000×1800mm (L*W*H) |

Best speed | 40~60 PCS/min |

Voltage | 380 V ,3 phase ,4 lines |

Ultrasonic Set | 2 Sets |

Machine Working Power | 5 KW |

Machine weight | 1200 kg |

Finished Sleeve Product Photo:

Advantages

No. | Difference | Picture | advantage |

1 | Produce Speed |

| 40-60pcs/min |

2 | Ultrasonic systems |

| There are ultrasonic devices set in the machine with good and stable quality which can make the non woven weld much more solid. |

3 | Electric box |

| We use the independent safety inspection electric control box, which can be operated open, agile and safe.

|

4 | frequency converter |

| We use “Inovance” frequency converter

|

5 | Fan |

| we used fan near the ultrasonic horn to reduce temperature of horn and extend the life of ultrasonic |

6 | Motor |

| Our gear motor is new and doesn't need to be fueled |

7 | air cylinder control |

| Machine rolls are controlled by air cylinder . |

8 | Computer controller |

| “Inovance” PLC touch screen controller

|

9 | Machine door close |

| The workers can’t start the machine without key if the door was closed, we can ensure the production safety in this way |

10 | Traction roller |

| We used silicon roller instead of butyronitrile roller as silicon roller with better abrasion resistance and will not crack. |

11 | Independent RM unwind |

| RM feeding part |

12 | Connect with cylinder |

| because there is air cylinder control device on the machine, so buyer needs to buy an air compressor to combined with the cylinder |

13 | Cutting blade mould |

| The cutting mould to cut the boot piece by piece |

16 | Automatic waste discharge device |

| Automatic waste discharge device, which can save a lot of labor and more efficient. Some manufacturers need to operate the waste part manually. |

17 | conveyor belt |

| We install the conveyor belt to collect the finished product, which can be set as a single or multiple stack to facilitate the customer's later packaging work |

Sleeve Machine Spare Parts List :

No. | Name | Qty |

1 | Adjustable Spanner | 1set |

2 | Allen wrench | 1set |

3

| Screwdriver | 1set |

4 | Screw | N pcs |

5 | Mould pad | 1 pc |

More info required, pls contact me at your convenience.

Attn: Walker He (Mr.)

Chipbest Technology (Dongguan) Co.,Ltd

Mobile/Whats App/Wechat: 008618928290625

Factory Address: No.44 Baofeng Road,Shijie Town,Dongguan City,Guangdong Province,China

https://chipbest.en.made-in-china.com/