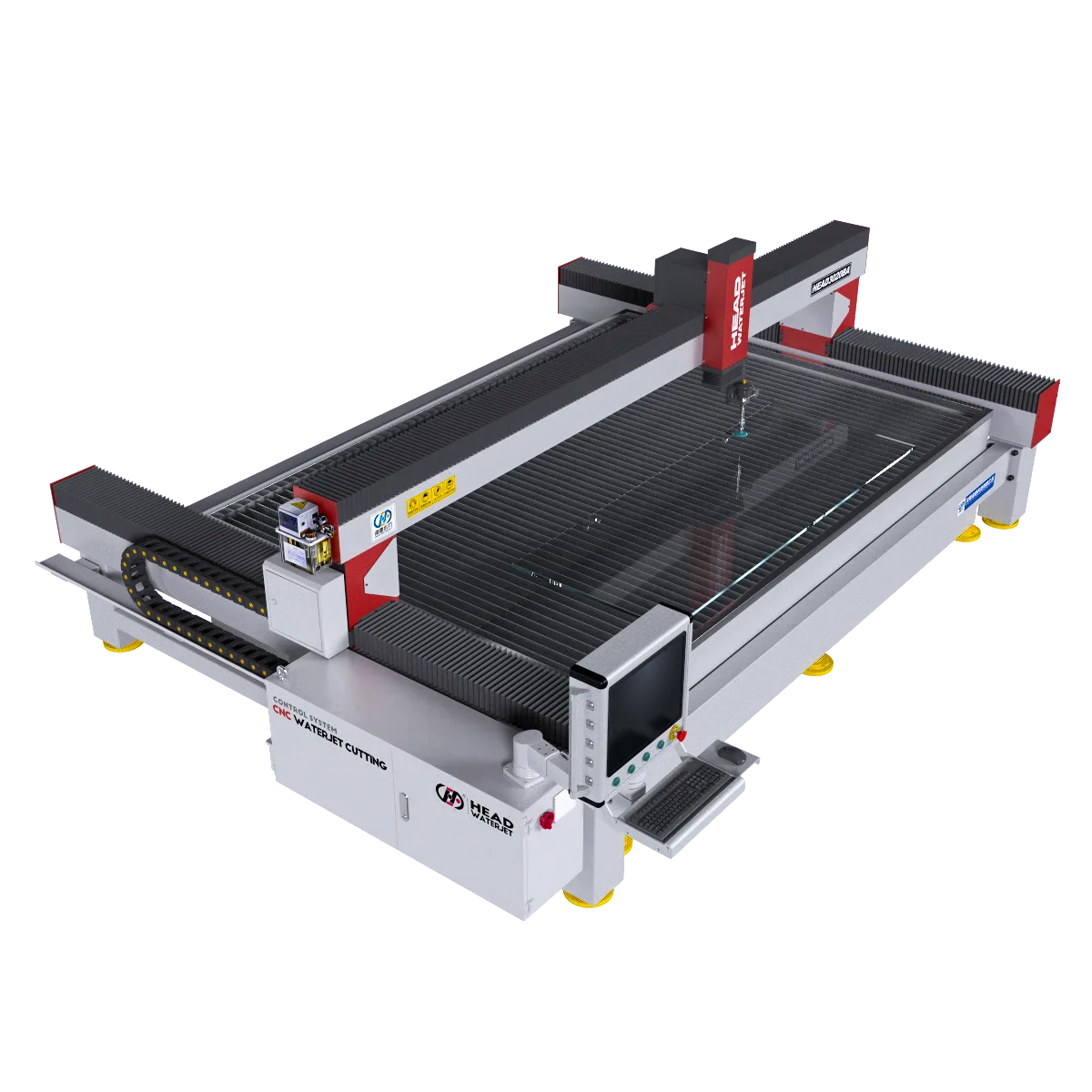

4000 мм * 2000 машина для резки стекла

- Категория: Glass Production Machinery >>>

- Поставщик: Shenyang,Head,Science,and,Technology,Corporation,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.72 $* | 0.74 $* |

| Aug-20-2025 | 0.68 $* | 0.61 $* |

| Jul-20-2025 | 0.81 $* | 0.17 $* |

| Jun-20-2025 | 0.90 $* | 0.2 $* |

| May-20-2025 | 0.10 $* | 0.36 $* |

| Apr-20-2025 | 0.45 $* | 0.95 $* |

| Mar-20-2025 | 0.49 $* | 0.33 $* |

| Feb-20-2025 | 0.12 $* | 0.56 $* |

| Jan-20-2025 | 0.29 $* | 0.42 $* |

Характеристики

Water jet laminated glass cutting machine prices

Waterjet cutting is a fast growing machine tool process, due to its versatility and capability to cut most types of materials, manufacturers are realizing that there are virtually no limits to what waterjets are capable of cutting. Major benefits of waterjet cutting include; no heat generated structural changes, cold cutting process, virtually burr free cut edges, reduces finishing operations and no material distortion or discolouration.

Product description:

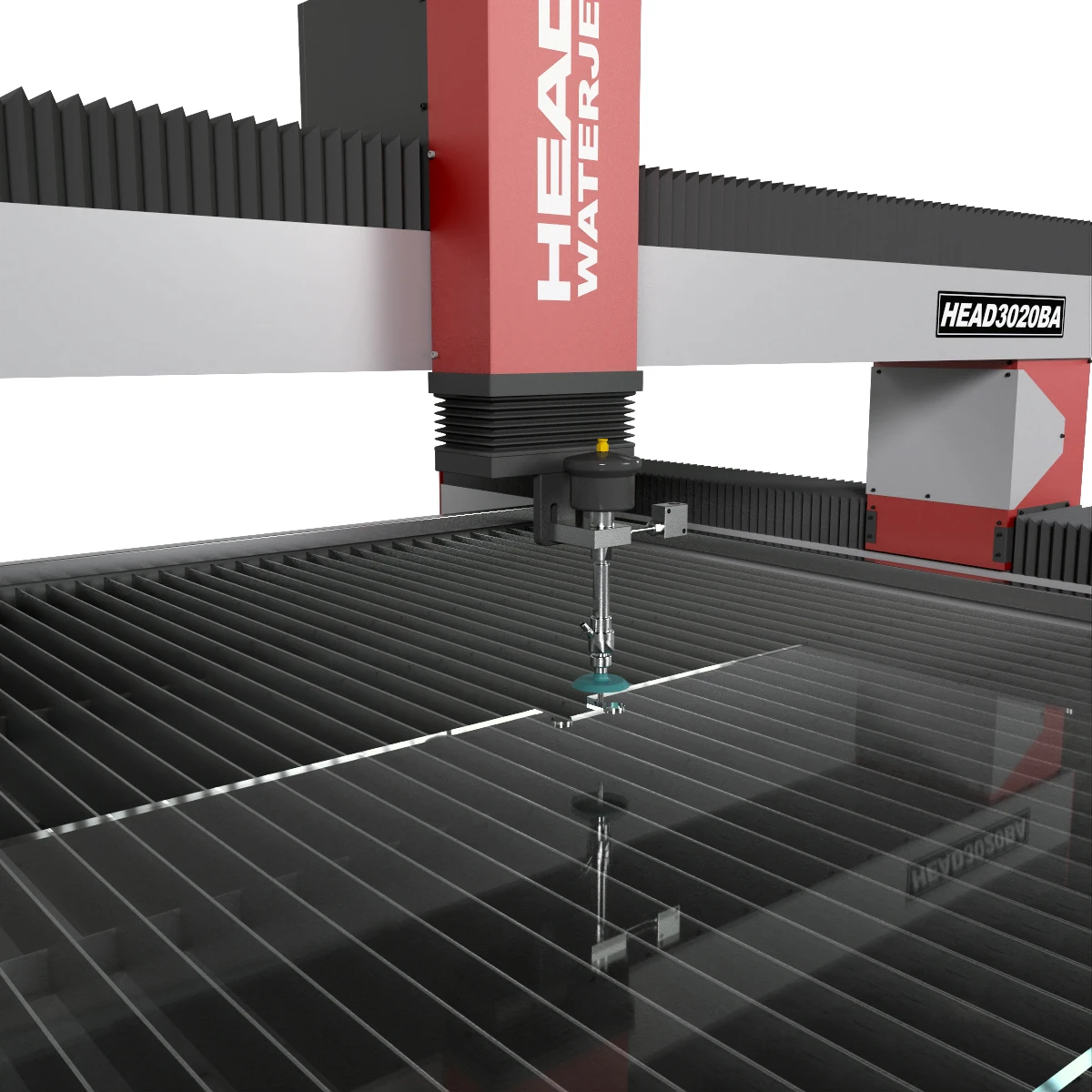

High precision AC five axis water cutting head, the high reliable absolute value encoder servo motor can be started without the origin switch, which saves the time of returning to the origin and reduces the mechanical failure of the whole machine. Precision 3D workpiece cutting can be achieved by using high precision and reliable speed reduction mechanism with positioning accuracy of 1.5arcmin

Features:

50 HP High 420 MPa pressure for smooth finish cutting at high speed.

Main heart of Supercharger, "Intensifier" is "Made in USA".

User friendly & minimum maintenance cutting head design with USA make "Water Switch Seal Kit" & other parts.

All parts of machine are processed on Highly accurate YASKAWA servo motor (made in Japan). Which gives you trouble free operation & long life of parts.

5 axis cutting head enables operators to cut bevels and mitre cuts up to 45 degrees. provides the option to activate a "taper compensation" setting which offsets the taper in the water stream to accurately achieve the desired angle

SPECIFICATIONS FOR WATER JET CUTTING MACHINE | ||||||

Max. pressure | 420MPA/60000psi | |||||

Max. flow rate | 3.7L / min | |||||

Electrical source voltage | 3 phases 220/380 Voltage, 50/60Hz, 37KW, 50HP | |||||

Max. diameter of nozzle / orifice | 1.02mm / 0.33mm | |||||

Max. delivery capacity of oil pump | 106L / min | |||||

Max cutting heads | 1-10 cutting heads (1 for standard machine) | |||||

IGEMS CAD/CAM/NEST for water jet cutter

IGEMS brand from Europe, the most famous 5 axis water jet software around the world.The 5 axis water jet software is from Sweden.The software can achieve auto-changing cutting angle when we are using the 5 axis. It can also control cutting speed when we cut line or corner to ensure cutting quality

IGEMS CAD: A software built in module allowing to create and modify drawings. Enables importing of drawings from various file formats, including *.cdr files. Clear interface and intuitional handling, similar to leading 2D CAD software.

DATA Exchange :A tool enabling import of files originating from different external software, without the need of their additional conversion. Useful particularly when using files with extensions different than *.DWG and *.DXF.

CAM Tools :This module includes 14 tools designed for optimisation of imported objects in terms of creating a working path for the tool. In several simple steps it is possible to erase hidden/duplicated contours, elimination of gaps in the contours or changing splines to vector lines.

AWJ : Add-in enabling optimisation of cutting speed for machines equipped with the abrasive cutting system.

Bevel :2 & 3D cuttingFrom now on you can import 3D files into IGEMS and place toolpaths on the contour of the model. This feature is something we've been working on for the past year and is something we are really proud of.There are plenty of settings in a 3D software, and we believe in things that are easy to use. So we stripped it down as much as possible to give you a light and fast 3D software for applying toolpaths.The module includes functions for defining surfaces/edges, adding toolpaths and customise leads, collision control etc. It's included in the regular Bevel module and can be downloaded by anyone with an update subscription.

HEAD floor type loading system

The cutting table adapts latest loading design, the max overturn angle is 85,the distance between loading material and ground is only 100 mm, max load-bearing is 1000 KG, hydraulic lifting and some other designs can meet the requirement of marble cutting. The situation many personnel are needed for loading material is changed, nowadays only 1 person is needed for the whole loading process. simple,convenient,greatly reduce the labor cost and minimize the marble breakage. This cutting table structure is 1st time adapted in domestic. It gains high praise once used by lots of marble processing clients.

A.\tPress the green button to start the turning of the system, at this time, the hydraulic station is supplying the hydraulic oil to the hydraulic cylinder.

B.\tPress the up button, the hydraulic cylinder begin to move, and the loading system begin to turn up

C.\tPress the red button to stop the loading system, when it stay in a certain angle level. Then you can put your cutting material on the system.

D.\tAfter you load your material, then press the down button, the loading system will go down and back to the water tank

water jet software

* Shanghai "WEIHONG"brand

* Easy to operate in just 8 hours to learn

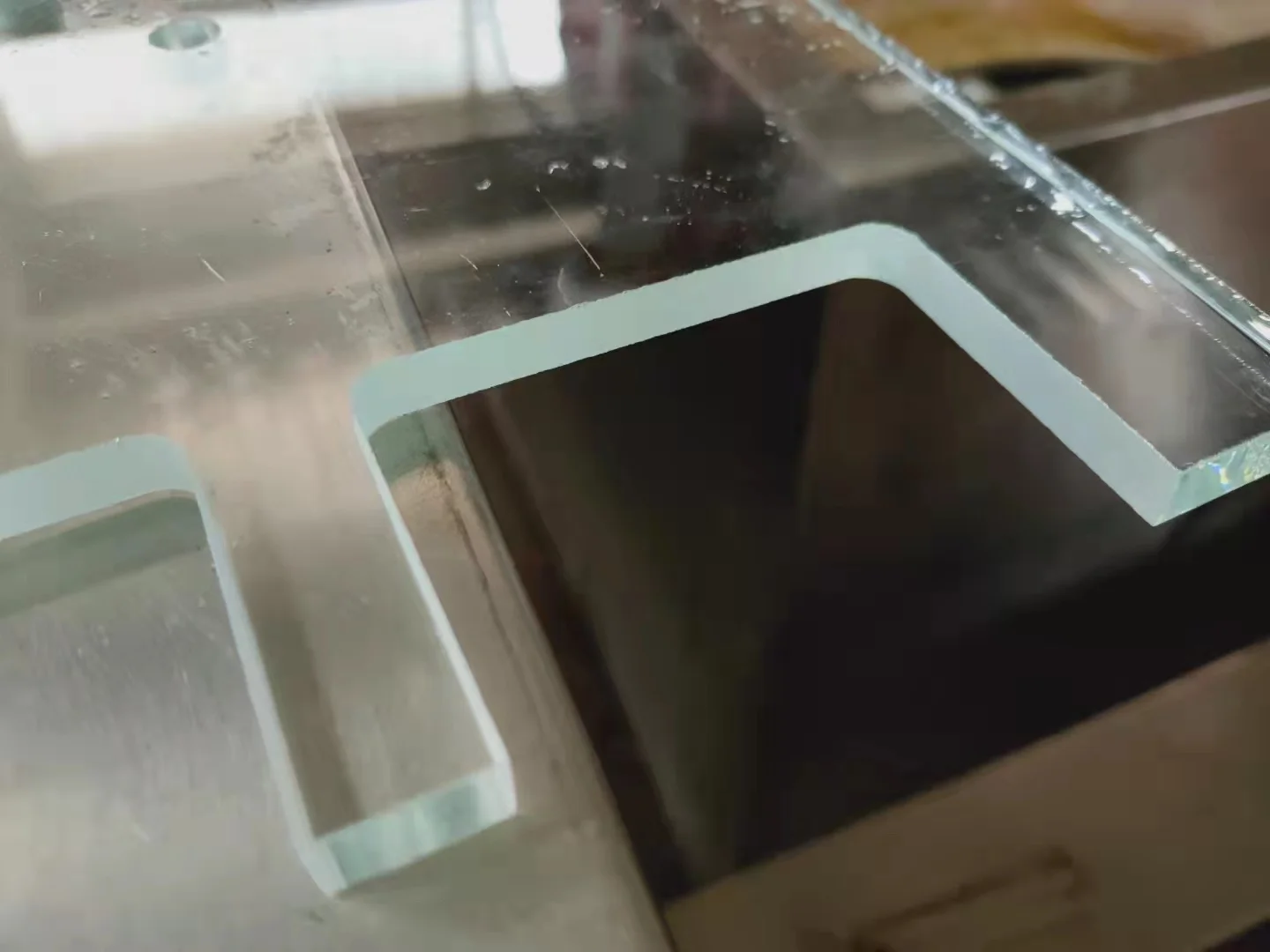

Cutting sample

Designed & manufactured to perfection, we are one of the well known and leading manufacturers and exporters of Water Jet Cutting Machinery. At our premises, we are manufacturing the cutting machinery utilizing premium quality of raw materials and components. In addition to this, the cutting machinery is best known in the market due to its remarkable features such as high performance, easy operation and durability. This Machinery finds usage in many application such as automotive, aerospace and electronics for cutting metals and non metals.

HEAD WATERJET has the complete produce and fabrication system, which has over 4000CBM factory and office, which can meet the Standardized 5s process Modular Production request, and can guarantee Quality and Quantity. Safe and Civilized according to Specifications, Process Operation,and Standard Acceptance.

Our company has the complete organizational structure, we have over 70 employees+30 global cooperative agents and engineers, and has the complete marketing, service, research and develop and production system which can supply the complete and on time service. We have ISO/EAC/CE/SGS/Alibaba Golden Supplier Certificate.

Double water and dust proof : pvc covers ( inner ) and stainless steel covers

for both X and Y axis

HEAD has 120 quality inspections and 80 durability test, which can guarantee the complete process technology and quality control. Heavy base body with vibration aging treatment after welding , in order to pretent the machine from shape out after Long working time. Milling by CNc Without vibration during machine working

Machine's X,Y lead screw's accuracy is calibrated and compensated by Renishaw Laser Interferometer system.

>>>Try to Read This -------Our Service

1. Maintenance free of charge for 12 months .

2. We will provide the consumable parts at an agency price.

3. 24 hours online service, free technical support.

4. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

5. We have manual instruction and Videos for software Installation, operation and machine's using and maintenance; We will send professional technician to customers' factory, provide them two-weeks training, including working principle of machine, Auto CAD drawing, common problems and solution, etc.

>>>Try to Read This -------FAQ

Q1: Does This Machine Pass CE Certificate?

A2: Yes, this machine passed European CE certificate and meet Safety Standard.

Q2: How much of cutting thickness?

A2: Marble is 0-120mm; granite is 0-110mm; tiles are 0-40mm; glass and mosaic is 0-80mm; steel, stainless steel, copper is 0-60mm; aluminum is 0-80mm; plastic, acrylic, foam is 0-200mm. With our double-pressures system, it can cut 0-160mm steel sheet, 0-200mm stones. It is good for customers cut thicker materials.

Q3: How fast of speed?

A3: Speed depends on cutomers' materials and cutting requirement, and customers can adjust speed parameters.

Our Package Advantage:

1. Our Wooden Case is after fumigation treatment. Needn't timber inspection,saving shipping time.

2. All the spare parts of the machine were bovered by some soft materials,mainly using Pearl Wool.

Avoiding all damages that could happen in the delivery process.Then we'll covered plastic wrap out it tightly, make sure intact of the covered soft materials,also avoiding Waterproof and rust proof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has firm iron jack,convenient to Handling and transport.

Before delivery, we would do the test about 20-30 working hours for machine, and use standard packing to each configuration. We choose famous export company and transport company, making shipment more convenient and safer.